Close

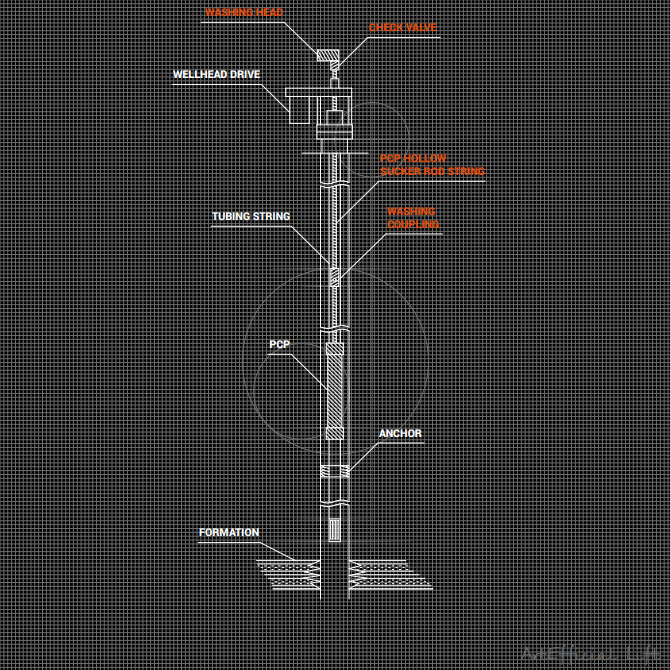

Transfer of torque from surface drive to PCP rotor, heating, flushing and removal of paraffin deposits from tubing. Hollow PCP rods are used as a rod string.

DEPARAFFINATION EQUIPMENT FOR PCP (OPPC)