- Home Newsroom

- Home Newsroom

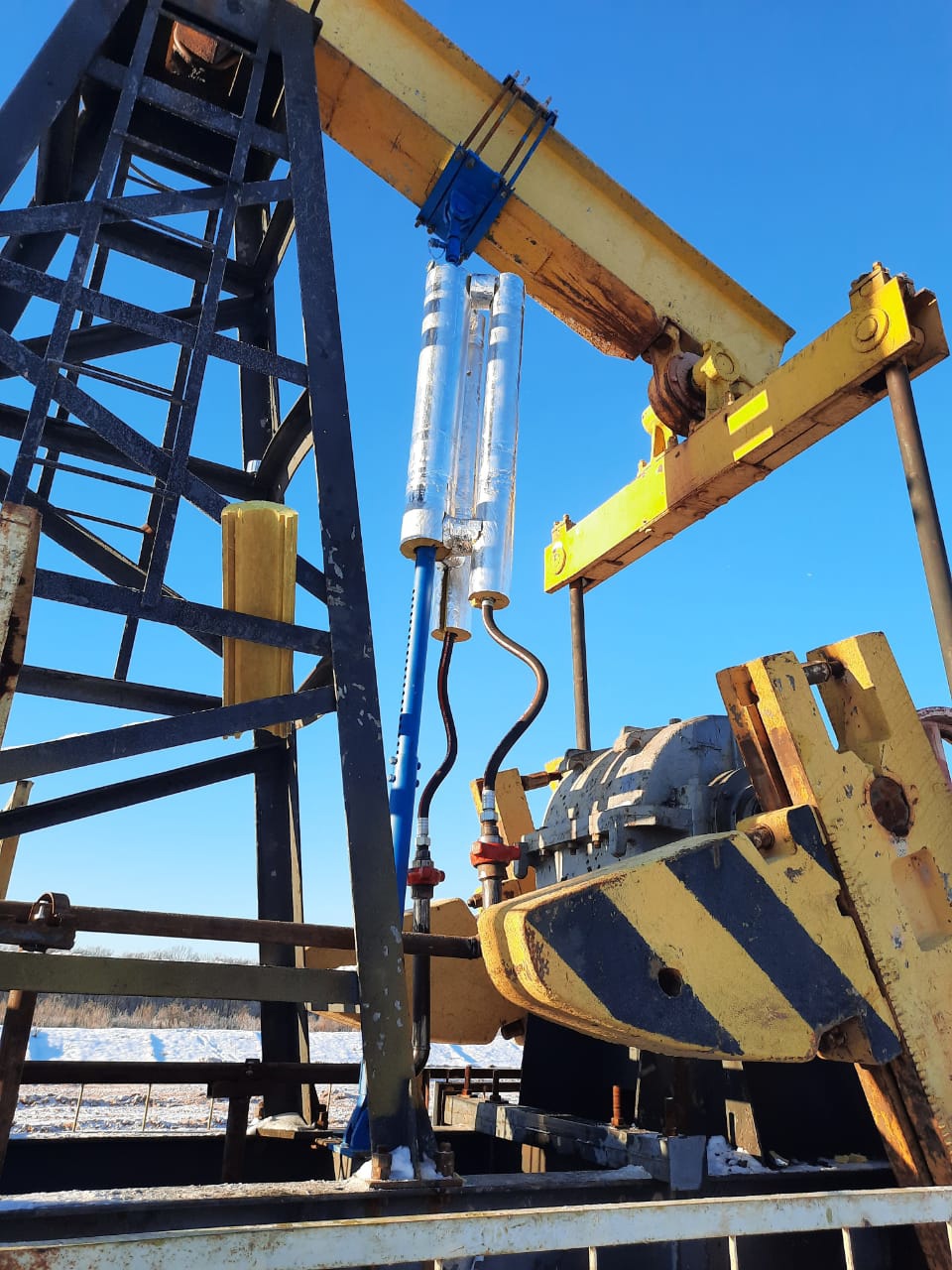

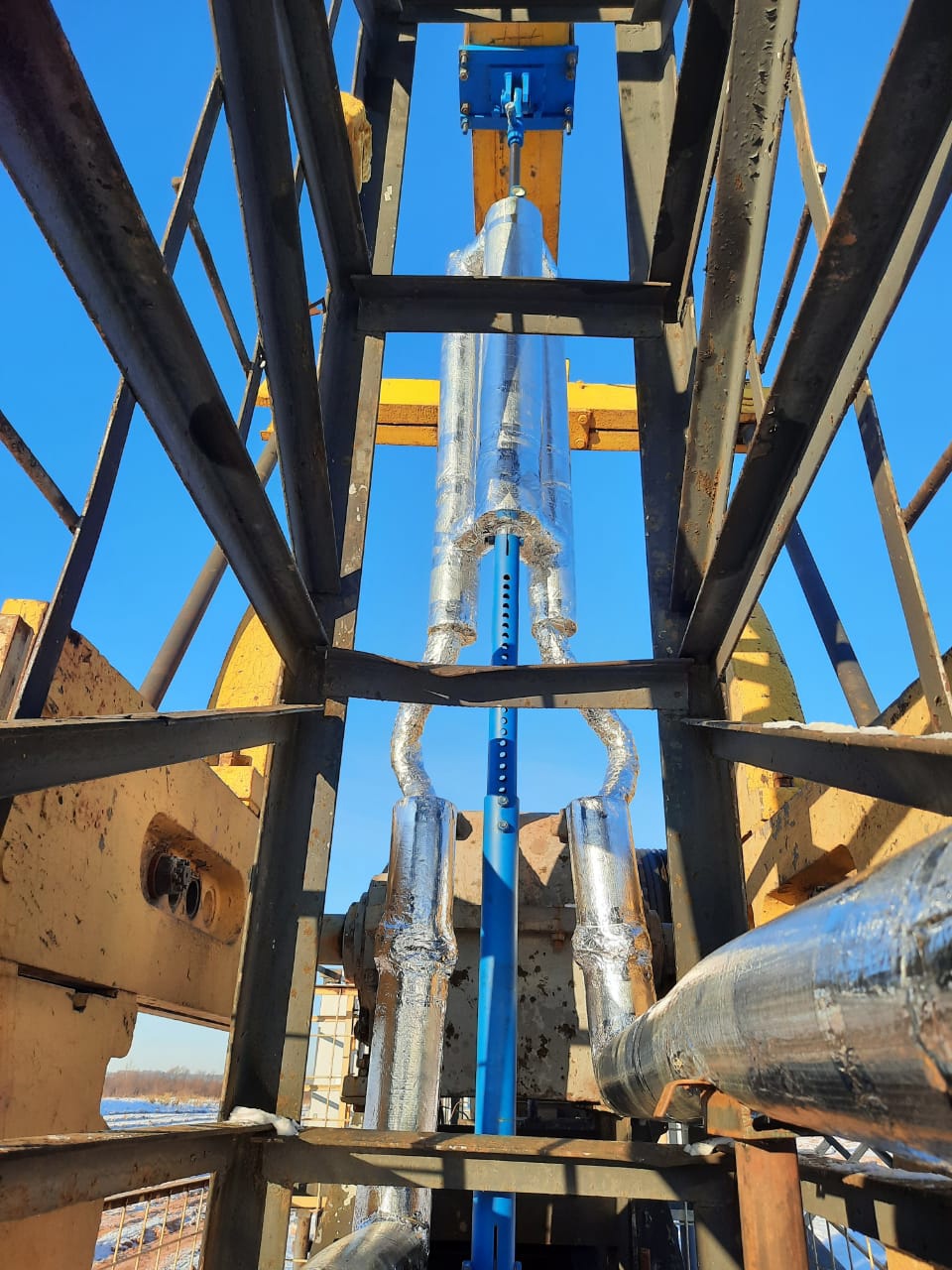

Efficient solution for annular degassing

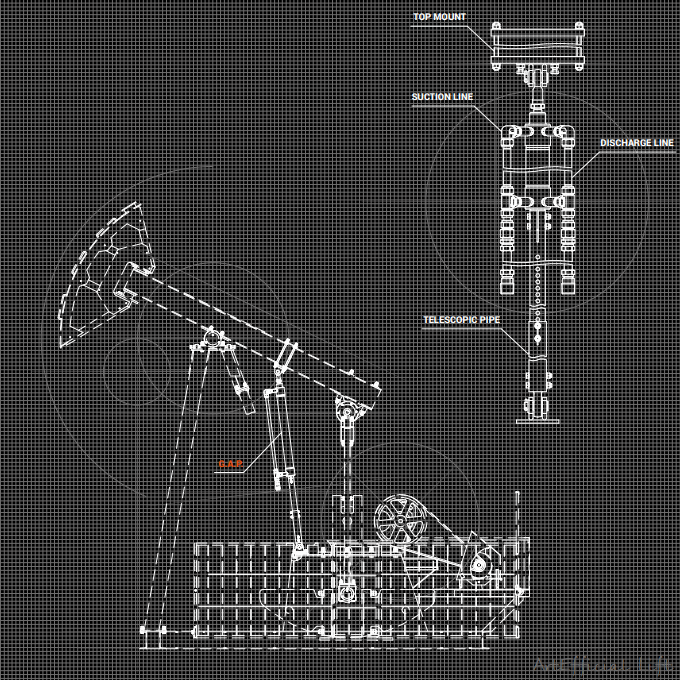

G.A.P. – gas annular pump – manufactured by ELKAM is designed for forced annular gas pumping driven by BPU. It is a double-stroke oil-filled pump with 1 meter stroke and flow rate up to 131 m3 per day

Application of this pump allows to increase SRP efficiency by increasing dynamic level, reduce risk of pump failure and to produce gas for subsequent regeneration

During field trial of gas annular pump in ROSNEFT the following results were achieved:

- • Increase of produced oil volume – 1,4 t/d

- • Increase of produced fluid volume – 4m3/d

- • Decrease of annular pressure for 70%

- • Increase of dynamic level for 81 m

The use of this technology will allow you to get an additional profit of 300 thousand rubles per year for one oil well

To learn more information about G.A.P. please call us at +73422495354 or mail us at td@elkam.ru

- Home Newsroom

Future specialists

Young personnel are valued in all industries, including the machinery manufacturing

One of the key areas of our company’s personnel policy is cooperation with young people

In May, a group of students of the Perm Polytechnic College named after N. G. Slavyanov completed their practical training at our factory, and last week second-year students of the Mining and Oil Faculty of the Perm Polytechnic University visited us to get acquainted with the manufacturing process

Nothing creates an image of a particular profession like a personal acquaintance with a specialist “in working process”, that’s why the students spent most of their time in the workshops, where they studied manufacturing route and observed production process

As an employer, we are interested in attracting young and promising personnel with proper qualification, so it is very important to lay in them the basic knowledge and practical skills of the future profession at the stage of their training

- Home Newsroom

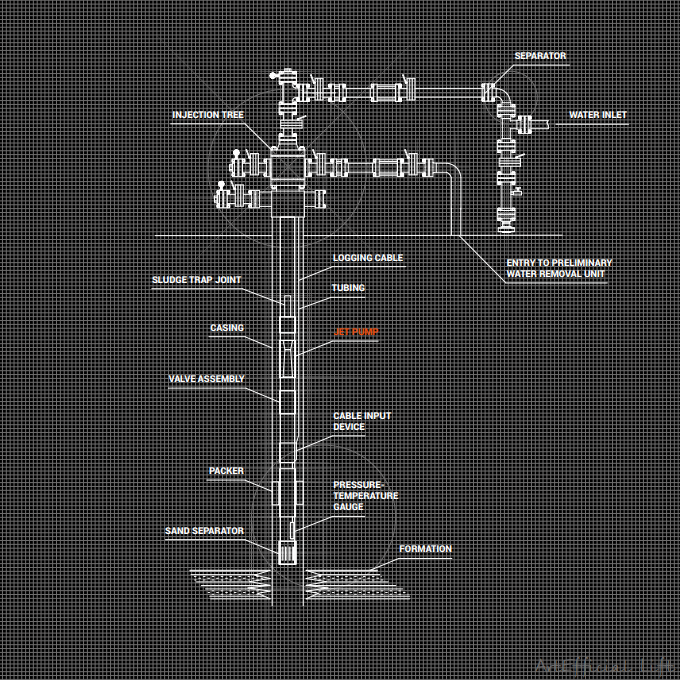

Jet pump

Application

- Oil production from wells complicated by high viscosity of produced fluid, high content of solids and free gas, where other methods are inefficient;

- Operation of sidetrack wells when jet pump is in sidetrack below dynamic level;

- New wells completion;

Advantages

- Small dimensions and simple design;

- No moving parts;

- Wide flow rate range;

- Smooth adjustment and hold down of bottomhole pressure and flow rate;

- Emulsion breaker is available;

- Jet pump replacement without tubing string pulling out;

- Operation with SAGD technology;

Benefits

- Operation of deviated wells;

- Stable production of high GOR formation fluid;

- Reduced time and cost for pump replacement;

Order reference

JET PUMP-ELKAM

Technical specification

- Flow rate bopd (m3 /d):

- up to 630 (100)

- Head, ft (m):

- up to 4920 (1500)

- Max. deviation angle, degree:

- up to 65

- Pumped fluid:

- multiphase mixture (oil-water-gas)

Peculiarity

Production method requires specific infrastructure – shot pits or water production wells, pumping units, high-pressure water pipeline, preliminary water removal units (PWRU).

- Home Newsroom

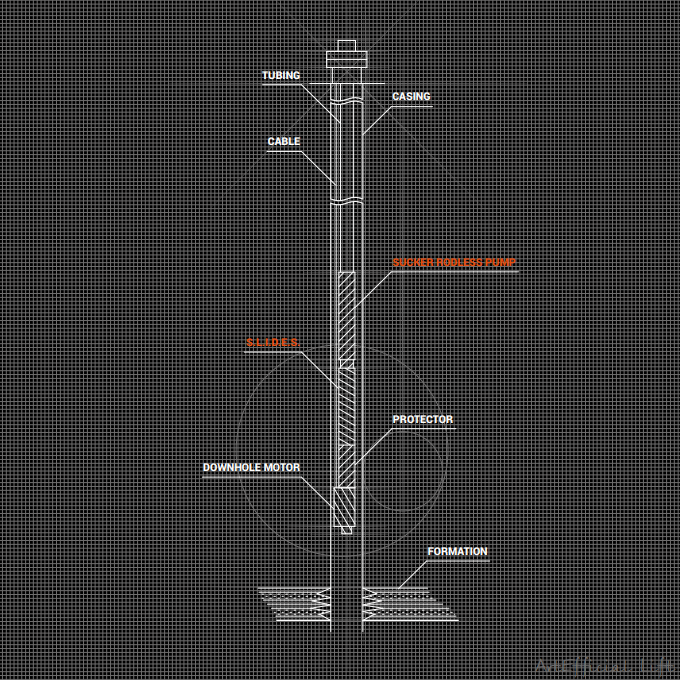

S.L.I.D.E.S. submersible linear drive equipment set

Application

Reciprocal motion transmission to plunger of sucker rodless pump thereby ensuring formation fluid production through tubing string without sucker rod string.

Advantages

- High reliability and efficiency;

- Low energy consumption;

- High efficiency due to use of displacement plunger pump;

- ELKAM control station and ELKAM-RM remote monitoring system provide: remote control, monitoring and realtime display of dynamograms;

Benefits

- Energy saving;

- Runlife over 5 years;

- No sucker rods required;

- No tear & wear of tubing;

- Operation in directional, deviated and horizontal wells;

- Maintaining operation of plunger pump while reducing dynamic level;

- Switch from intermittent to permanent operation;

Technical specification

| SLIDES ELKAM-35 | SLIDES ELKAM-50 | SLIDES ELKAM-80 | |

|---|---|---|---|

| Supply voltage, V | 380 | 380 | 380 |

| Output voltage, V | 600 | 1140 | 1140 |

| Rated current, А | 40 | 45 | 70 |

| Max. power, kWt: | 35 | 45 | 70 |

| OD, mm | 114 | 114 | 143 |

| Weight, kg | 452 | 520 | 945 |

| Double strokes per minute | up to 8 | up to 8 | up to 8 |

| Stroke length, m | 1200 | 1200 | 1200 |

| Thrust rating, kg | 2500 | 3500 | 6000 |

| Operating temperature, °С | 150 | 150 | 150 |

| Pump nominal size | 35 / 38 / 44 | 32 / 38 / 44 / 50 | 38 / 44 / 50 / 57 |

| Max. pump installation depth, m | 2400 / 2000 / 1500 | 3000 / 2500 / 1600 / 1400 | 3000 / 2600 / 2100 / 1600 |

| Ideal flow rate, m3 /day | 10 / 15 / 20 | 10 / 15 / 20 / 26 | 15 / 20 / 26 / 35 |

| Additional equipment | oil-immersed transformer | oil-immersed transformer | oil-immersed transformer |

- Home Newsroom

G.A.P. gas annular pump

Application

Forced annular gas pumping driven by beam pumping unit.

Advantages

- No need for gas treatment and purification;

- Installation on any pumping unit without interfering structure;

- No additional drive for G.A.P. is required;

- Gas meter installation is available;

Benefits

- Increased SRP efficiency by increasing dynamic level;

- Reduced risk of pump failure;

- Additional gas production for subsequent regeneration;

- Installation without workover crew;

Order reference

GAP-95-M

Technical specification

- Design type:

- double-stroke oil-filled

- Stroke, ft (m):

- 3.2 (1)

- Operating pressure, MPa (Psi):

- up to 4 (580)

- Flow rate, bopd (m3 /d)*:

- GAP-95-M two-stroke 820 (131)

* At 7 strokes per minute and stroke length of 1 m

- Home Newsroom

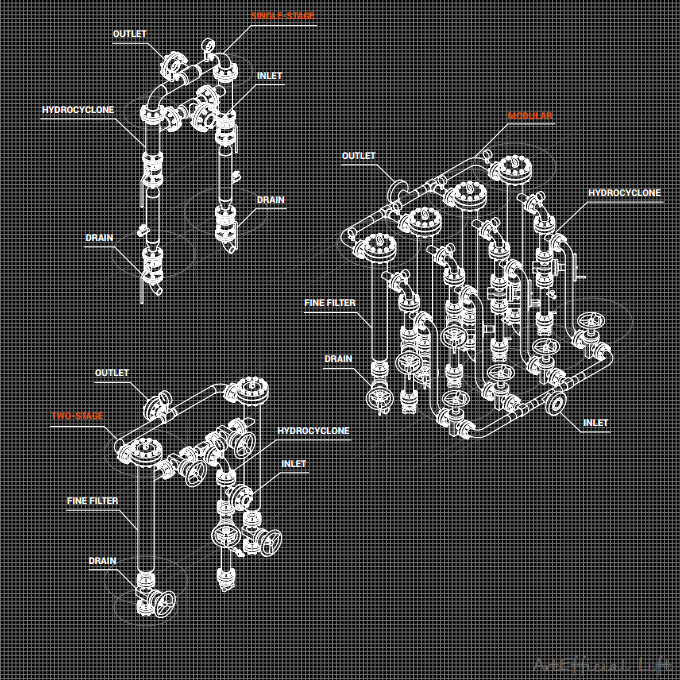

W.I.F.E. water injection filtering equipment

Application

Cleaning of process water from mechanical impurities in reservoir pressure maintenance systems in oil industry.

Advantages

- Rated fineness of cleaning from 1 μm;

- Installation on modular group pumping station, cluster pads and injection wellhead is possible;

- Long service life of filtering elements;

- Backflushing of filters with no need stop water injection into the well;

- Different modifications: modular design, number of modules depending on required flow rate;

- Simple and reliable design;

Benefits

- Maintenance of wells injection capacity;

- Reduced impact of solids on pumping equipment in reservoir pressure maintenance systems;

- Compliance with oil production company standards for suspended solids content in injected water;

- Reduced workover cost to restore well injection capacity;

Order reference

W.I.F.E.-21*-500**

Technical specification

- Operating pressure*, Psi (MPa):

- up to 5076 (35)

- Nominal pipe size, inch (mm):

- from 2.5 (65)

- Operating fluid:

- fluids used in reservoir pressure maintenance systems (fresh water, reservoir water, produced water)

- Flow rate**, bopd (m3 /d):

- from 315 (50)

- Nominal filtering capacity (particle size), μm:

- from 1

- Sample design:

- Two-stage (hydrocyclone + fine filters)

- Home Newsroom

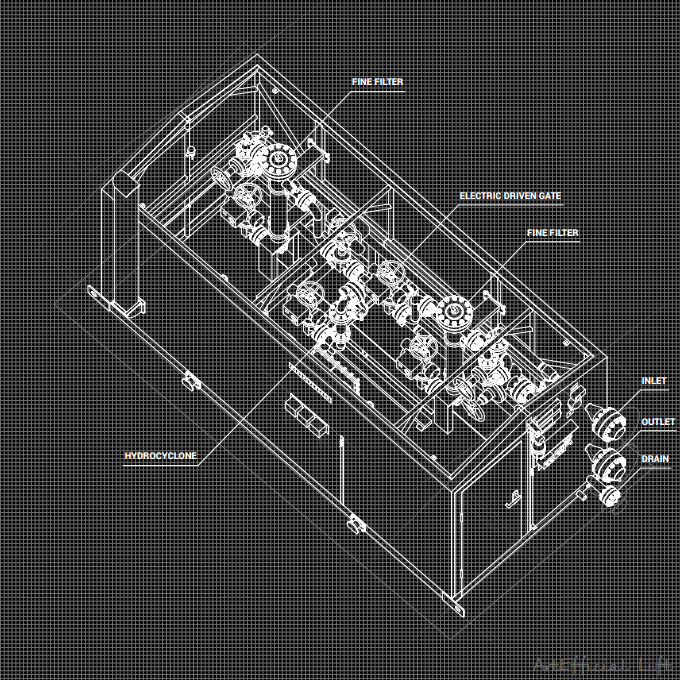

Automated W.I.F.E.

Application

Cleaning of process water from mechanical impurities in reservoir pressure maintenance systems in oil industry.

Advantages

- Automated washing without system stop;

- Rated fineness of cleaning from 1 μm;

- Installation on modular group pumping station, cluster pads and injection wellhead is possible;

- Long service life of filtering elements;

- No need to stop injection in order to backwash filters;

- Different modifications: modular design, number of modules depending on required flow rate;

- Simple and reliable design;

- Remote system operation control;

- Data transmission: pressure, differential pressure, temperature, number of the operating filter (state of valves);

- Operation in low temperatures and in remote fields;

- Removable roof panels for filter maintenance;

Benefits

- Maintenance of wells injection capacity;

- Reduced impact of solids on pumping equipment in reservoir pressure maintenance systems;

- Compliance with oil production company standards for suspended solids content in injected water;

- Reduced workover cost to restore well injection capacity;

- Reduced maintenance cost due to automated operation;

Order reference

W.I.F.E.(А)-21*-500**

Technical specification

- Operating pressure*, MPa (Psi):

- up to 35 (5075)

- Nominal pipe size, inch (mm):

- From 2.5 (65)

- Operating fluid:

- fluids used in reservoir pressure maintenance systems (fresh water, reservoir water, produced water)

- Flow rate**, bopd (m3 /d):

- up to 3144 (500)

- Nominal cleaning rate (particle size), μm:

- from 1

- Sample design:

- Two-stage (hydrocyclone + fine filters)

- Gate valve drive type:

- electrical explosion-proof

- Home Newsroom

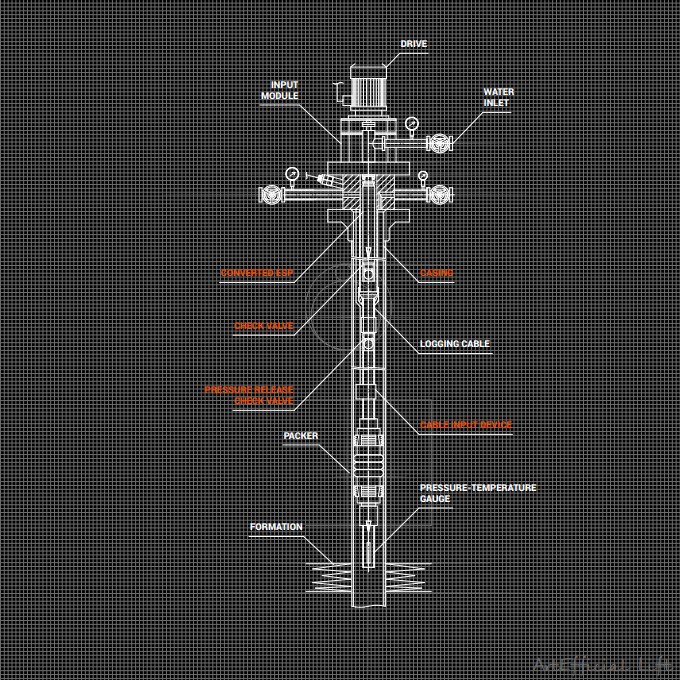

S.W.I.S. surface water injection system

Application

Separate water injection into discharge wells in reservoir pressure maintenance systems.

Advantages

- Installation within 1 RIH/POOH operation;

- Pump and drive replacement without well killing;

- Easy wide-range injection control;

- Use of TMS data for injection control;

- Safe tubing pressure release into annular space during workover;

- Well killing and discharge equipment included;

Benefits

- Use of low pressure pipelines in reservoir pressure maintenance systems;

- Specified geological parameters achieved through controlled injection;

- Reduced maintenance and repair cost;

Order reference

S.W.I.S.-300*-1500**

Technical specification

- Flow rate*, bopd (m3 /d):

- up to 10065 (1600)

- Head**, ft (m):

- up to 6890 (2100)

- Valve drive type:

- explosion-proof asynchronous electric drive

- Motor location:

- surface (at wellhead)

- Control box:

- with VFD

- Pump type:

- converted ESP

- Max. inlet pressure, MPa (Psi):

- 3 (435)

- Overpressure/depressure protection:

- ECM, TMS

- Home Newsroom

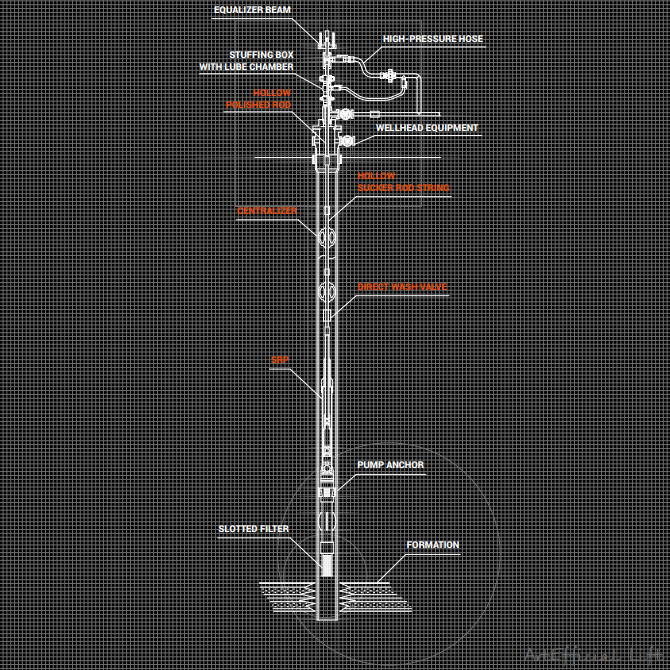

Tubing-free production set

Application

Operation of small ID casing.

Advantages

- Installation of downhole pumping equipment within 1 RIH/POOH operation;

- No tubing string required;

- Direct washing of paraffin from hollow sucker rod string;

- Dynamic level metering;

- Simple design and operation;

Benefits

- Reduced time and cost for RIH/POOH operations;

- Reduced metal consumption by at least 20%.;

Order reference

TUBING-FREE PRODUCTION SET

Technical specification

- Tubing string ID, inch (mm):

- 3 1/2 (89), 4 (102)

- Flow rate, bopd (m3 /d):

- up to 250 (40)

- Unit max. setting depth, inch (m):

- up to 5905 (1800)

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia