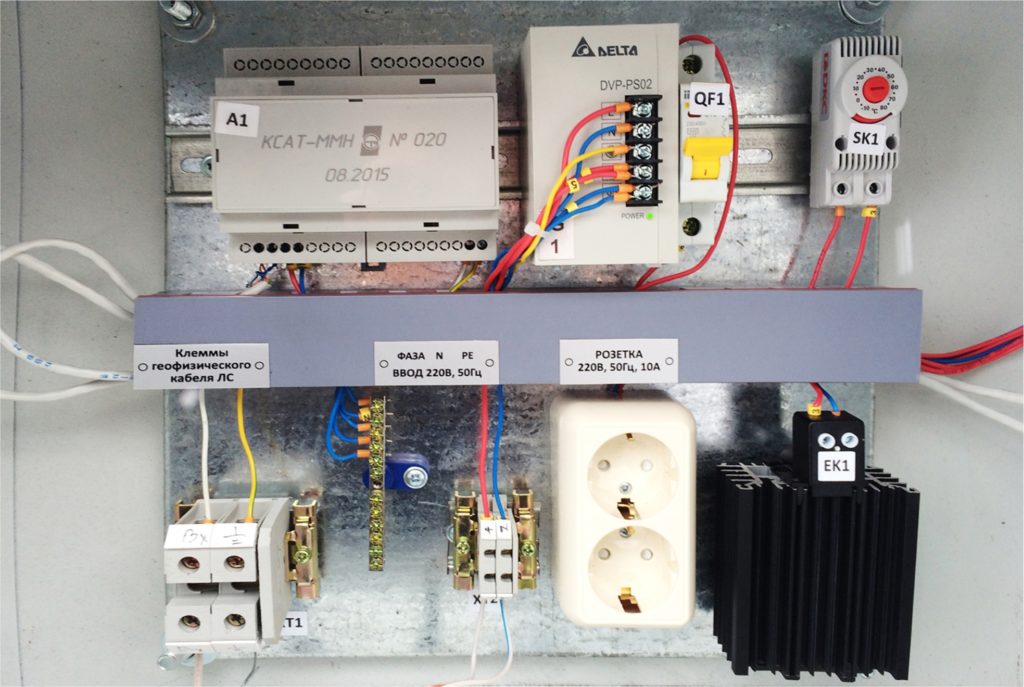

Control box telemetry units

Surface unit (KSAT-MMN) located inside the box of telemetry unit is used for collecting real time data getting from downhole unit and transferring it to control device through the port «RS-485 / RS-232». Surface unit is placed near (or inside) control box of electric (motor) drive of pumping set. The units have the following functional options: simultaneous monitoring of well condition without lift; display of information from 3 downhole modules simultaneously; storing of information in internal control box storage during 1 year; transferring data to any digital storage devices; display of current condition of downhole equipment on digital screen, etc.

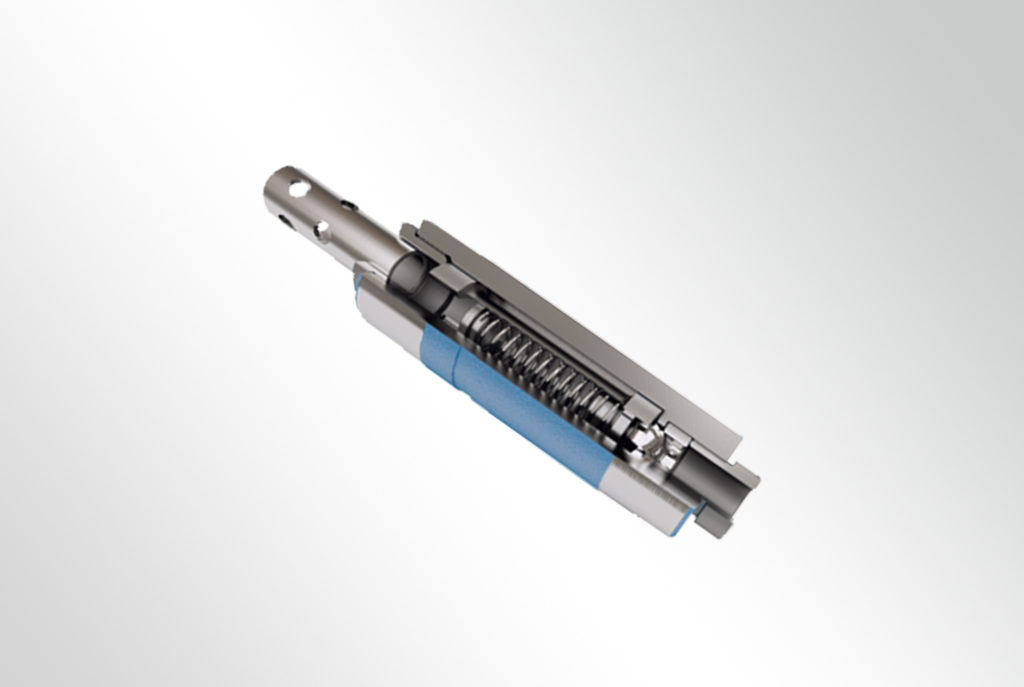

Input module

Input module joints with protector shaft by splined couplings at the bottom and with the shaft of ESP bottom section at the top so that during ESP unit operation rotation of motor shaft and protector is transferred through the module to pump sections. In addition input module can filter formation fluid from solids and serve as gas regulator (stabilizer).

Submersible logging tools

Submersible logging tools are used for online monitoring, registration and transferring current parameters of equipment operation to external devices. The parameters are the following: circuit insulation resistance, pressure and temperature of formation fluid, volume water content. Submersible logging tools include downhole well module KSAT-MMP and surface unit KSAT-MMN. They serve for simultaneous measuring and storing technological parameters; long-time monitoring of wells without lift; generating and transferring data to personal computer; information reading from the storage of surface unit without recording braking and pulling out downhole module from well, etc.

Wire

Submersible wire is a flat armored three-core cable. Its length depends on setting depth of downhole part of ESP. This wire is round at the surface up to the setting depth. Its downhole part alongside the pump and protector is flat. Wire change from round to flat is hot spliced. Its actual (manufactured) length is 800 -1800 meters. Power loss is 25-125 V per each 1000 meters.

Control box electric submersible pump set

For optimization and automatization of oil production process and also for decreasing of expenses for power consumption our company develops and manufactures control boxes which are able to ensure full protection of the whole pumping system preventing accidents. Also they ensure full independence of operations even in the simplest package. ELKAM’s line of control boxes include VSD and intellectual control boxes with the ability of connection of additional control devices (telemetry systems; sensors of pressure, vibration, temperature, rod position; etc.)

Blow-out preventers (BOP)

ELKAM provides blow-out preventers (BOPs) made from high-grade cast iron with carbon steel rams manufactured in accordance with the Russian standards GOST 27743 and GOST 13862-90. BOPs are used for wellhead sealing and as the result for preventing oil spill during well maintenance and normally operate at the temperature from 55 °С above zero to 40 °С below zero.

Valves

Range of valves manufactured by ELKAM operated with progressive cavity pumps includes check valves designed for reliable holding of fluid within tubing string and pipeline upon pump shutdown, combined valve assemblies, buffering valves used for decrease of wellhead pressure, drain valves (membrane, with breakable plug), shutoff and flush valves used for direct washover of tubing from asphalt-resin-wax deposits (ARWD).

Torque anchor

Torque anchor is used for fixation of PCP stator inside casing upon pumping set operation. Its application excludes unwinding of tubing and pump during pump operation. ELKAM supplies anchors for casing 140, 146 and 168 mm with various wall thickness. The main advantages of these anchors are high reliability anchoring regardless of well pressure, decrease of frequency and period of well repairing, low price.

Wire progressive cavity pump set

Wire is used for power supply to downhole (electric centrifugal or progressive cavity) pumps. It is being operated in extremely severe conditions: high temperatures, influence of high hydrostatic pressure, rapid changes of temperature and pressure, oil products insertion, tensile stresses. ELKAM supplies wires manufactured in accordance with the Russian standard GOST and adapted to these conditions as much as possible.

Wellhead equipment

Wellhead equipment is used for hermetic sealing and flow spreading of fluid and injecting chemicals as well as for tubing hanging. ELKAM provides various types of wellhead equipment for different well operation methods including simultaneous oil production and injection.

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia