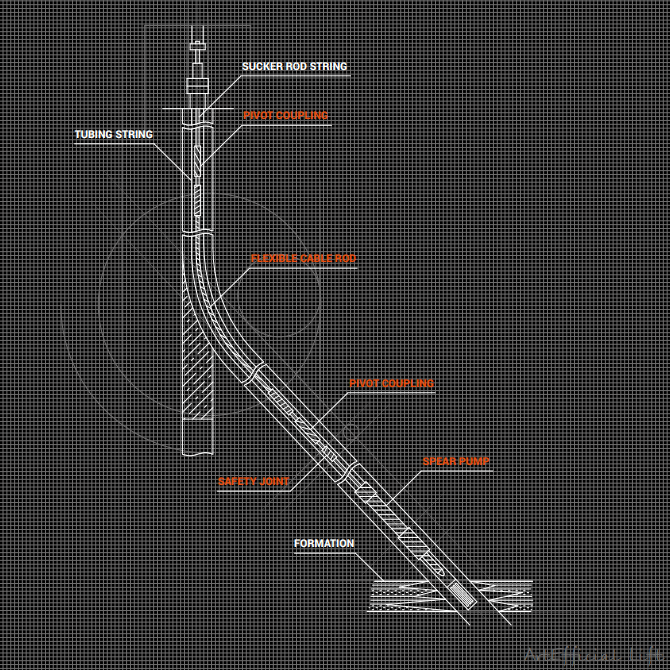

Flexible cable rod set

Application

SRP oil production from sidetracks and horizontal wells.

Advantages

- Sidetrack well operation with deviation angle up to 90 degrees;

- SRP sidetrack installation;

- No spot tear & wear by sucker rod couplings;

Benefits

- Increased oil production due to downhole equipment deeper installation;

- Increased efficiency of pumping system due to bigger setting depth;

- Reduced failures due to tear & wear of tubing and rod string in deviated sections;

- Reduced sucker rod string breakage;

- Reduced surface drive energy consumption and loads due to smaller cable rod weight;

- Fast (dis-) assembly;

Order reference

FCR SET

Technical specification

- Recommended pump type:

- SPeaR

- Casing ID, inch (mm):

- not less than 3 1/2 (89)

- Well slope angle at pump installation point, degree:

- up to 90

- Tubing OD, inch (mm):

- From 2 3/8 (60)

- Cable rod length, ft (m):

- up to 3280 (1000)

- Max. operating load at top joint, kN:

- 100 (customized according to well data)

- Dynamic viscosity of pumped fluid, Pa·s (cP):

- up to 0.25 (250)

- Max. pump setting depth, ft (m):

- up to 7215 (2200)

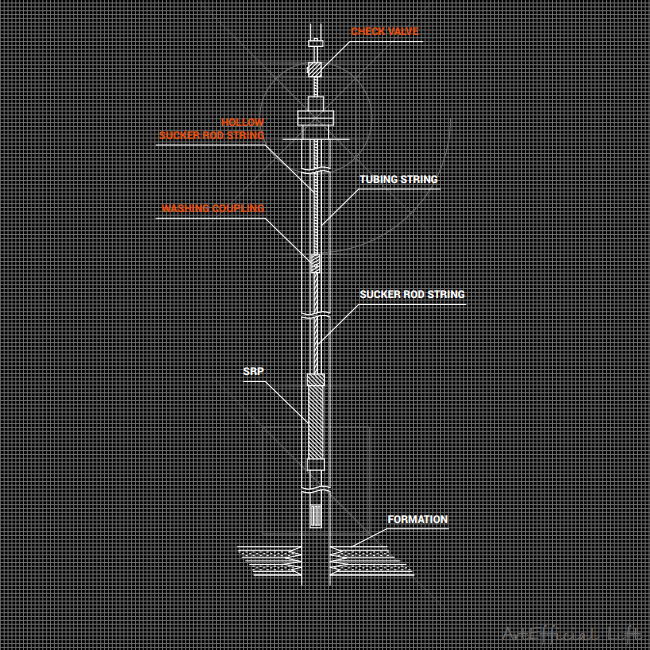

Deparaffination equipment for SRP

Application

Heating, flushing and paraffin removal from tubing during SRP operation. Hollow rods are used for heating agent supply.

Advantages

- Reduced heat loss of washing fluid;

- Faster heating and paraffin removal;

- Flushing without SRP pumping unit stop;

- No SRP clogging during flushing;

Benefits

- Reduced washing fluid volume;

- Reduced washing time;

- No impact on formation during washing;

- Flushing of tubing in wells absorbing formations;

Order reference

DEPARAFFINATION EQUIPMENT FOR SRP (OPPC)

Technical specification

- Tubing OD, inch (mm):

- from 2 7/8 (73)

- Length of hollow sucker rod string, ft (m):

- up to 4920 (1500)

- Flow rate of hollow sucker rod, l/min:

- up to 130

- Flushing pressure, MPa (Psi):

- up to 0.9 (140)

- Washing fluid temperature, °F (°С):

- up to 572 (300)

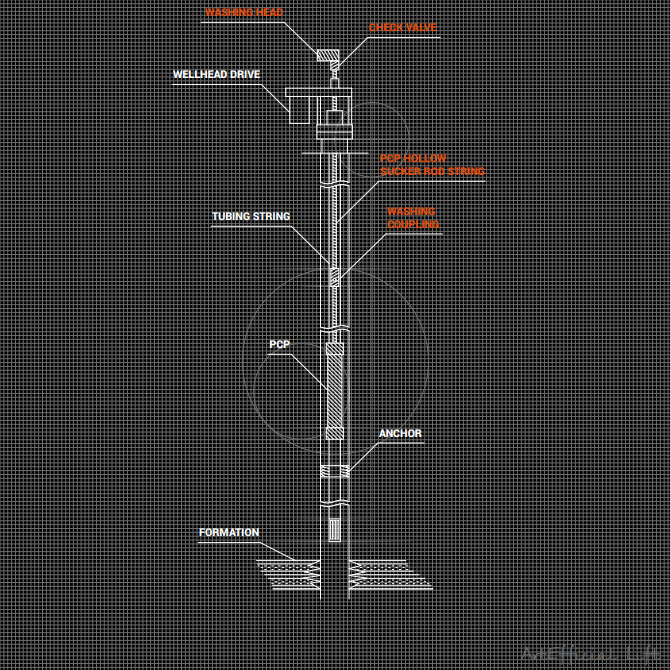

Deparaffination equipment for PCP

Application

Transfer of torque from surface drive to PCP rotor, heating, flushing and removal of paraffin deposits from tubing. Hollow PCP rods are used as a rod string.

Advantages

- Reduced heat loss of washing fluid;

- Faster heating and paraffin removal;

- No PCP clogging during flushing;

- Coupling-free connection;

- Increased flow area between rod and tubing;

- Transferable torque by hollow sucker rods 1.5 times higher than that of similar solid sucker rods;

Benefits

- Reduced failures due to tear & wear of tubing and rod string;

- Reduced washing fluid volume;

- Reduced washing time;

- No impact on formation during washing;

- No need for rotor removal for tubing washing;

Order reference

DEPARAFFINATION EQUIPMENT FOR PCP (OPPC)

Technical specification

- Tubing OD, inch (mm):

- from 2 7/8 (73)

- Length of hollow sucker rod string, ft (m):

- up to 4920 (1500)

- Flow rate of hollow sucker rod, l/min:

- up to 90

- Flushing pressure, MPa (Psi):

- up to 0.9 (140)

- Washing fluid temperature, °F (°С):

- up to 248 (120)

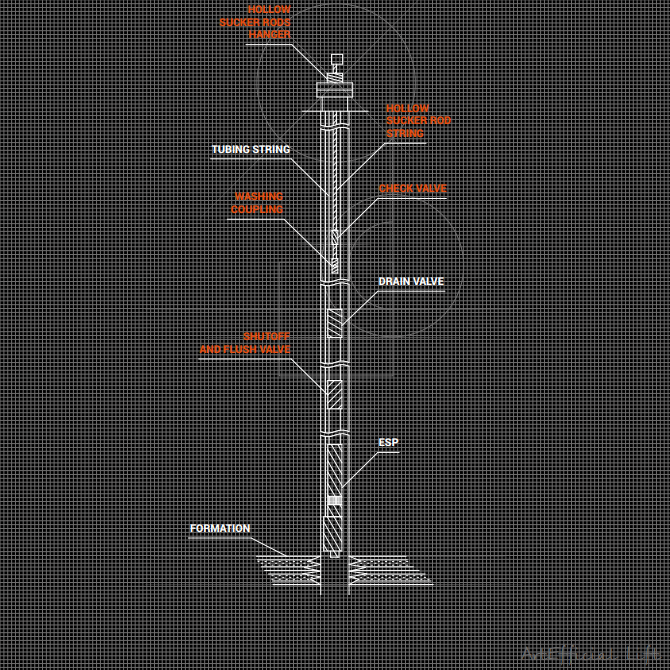

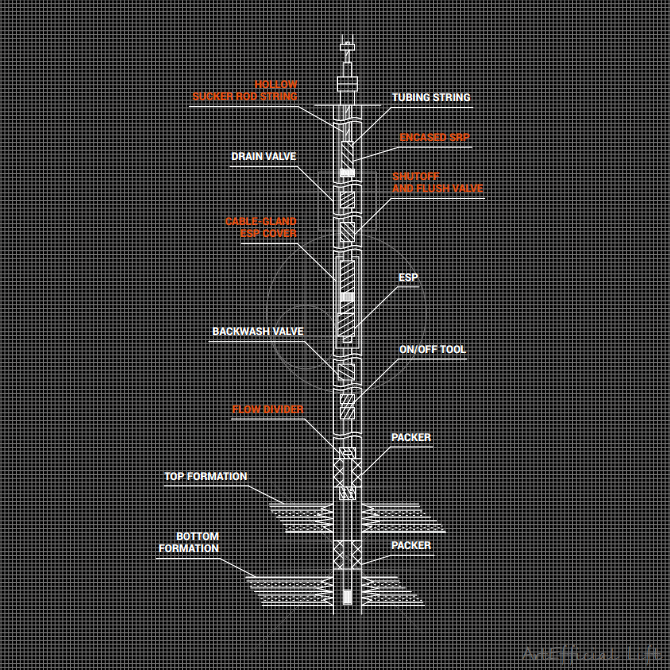

Deparaffination equipment for ESP

Application

Heating, flushing and paraffin removal from tubing using ESP. Hollow rods are used for heating agent supply.

Advantages

- Reduced heat loss of washing fluid;

- Faster heating and paraffin removal;

- Washing without ESP stop;

- Supply of reagent to target area;

Benefits

- Reduced washing fluid volume;

- Reduced washing time;

- No impact on formation during washing;

- No need for additional surface well infrastructure (as compared with scraper);

Order reference

DEPARAFFINATION EQUIPMENT FOR ESP (OPPC)

Technical specification

- Tubing OD, inch (mm):

- from 2 7/8 (73)

- Length of hollow sucker rod string, ft (m):

- up to 6560 (2000)

- Flow rate of hollow sucker rod, l/min:

- up to 130

- Flushing pressure, MPa (Psi):

- up to 1.4 ( 210)

- Washing fluid temperature, °F (°С):

- up to 572 (300)

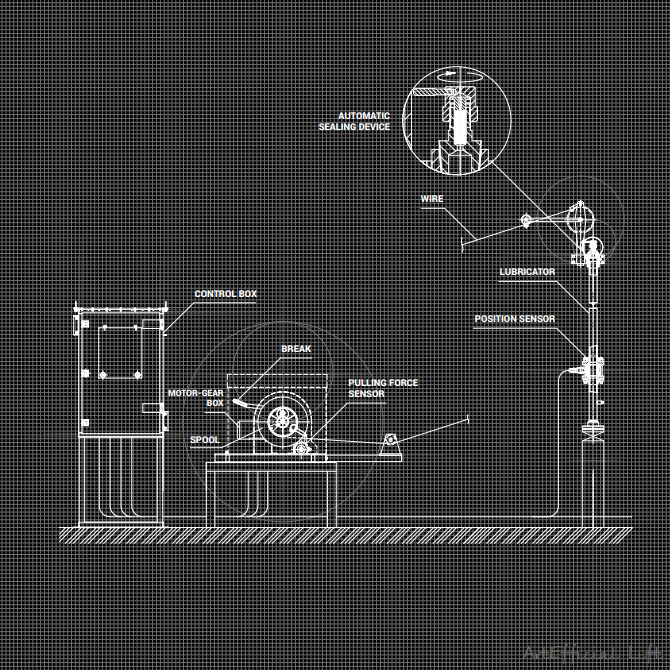

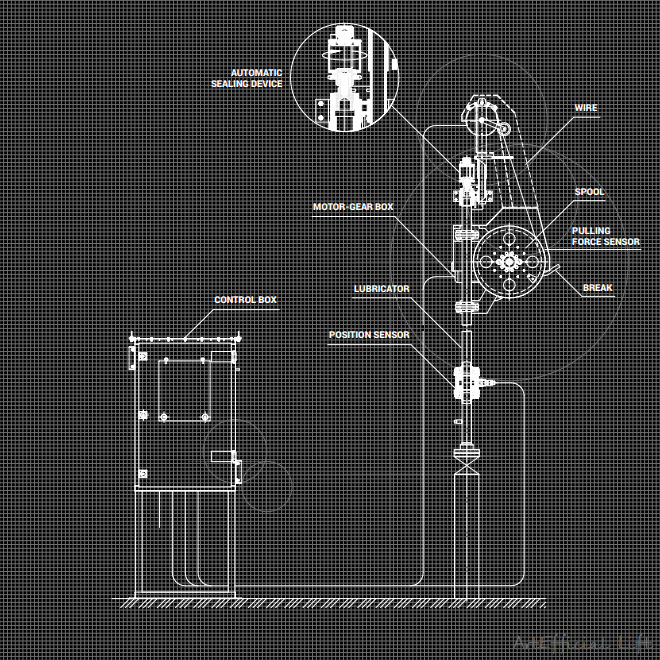

Well deparaffination unit

Application

Mechanical deparaffination of tubing (with scrapers) for wells with natural flow, ESP and ESPCP.

Advantages

- Wire tension control;

- Ratchet joint of drive shaft and spool to prevent reverse winding of wire;

- Unit status monitoring in case of power cut;

- Winch is turned off when pump is stopped;

- Handbrake to set scraper in free fall mode;

- Emergency alarm;

- Automatic sealing device;

- Remote data monitoring and transfer;

- Manual removal of paraffin plugs;

Benefits

- Increased well runlife and cleaning interval;

- Preserved flow rate;

- Easy operation and maintenance;

- High repairability;

Technical specification

| WDU 80/ WDU 80А | WDU 100/ WDU 100А | WDU 80WА Wellhead unit | WDU 63WA Wellhead unit |

|

|---|---|---|---|---|

| Cleaned tubing OD, inch (mm) | from 2 (48) | from 2 (48) | from 2 (48) | from 2 (48) |

| Lubricator max. operating pressure, MPa (Psi) | up to 35 (5076) | up to 35 (5076) | up to 35 (5076) | up to 35 (5076) |

| Nominal lubricator size, inch (mm) | 2.55 (65); 3.14 (80) | 2.55 (65); 3.14 (80) | 2.55 (65); 3.14 (80) | 2.55 (65); 3.14 (80) |

| Max. cleaning depth, ft (m) | 6560 (2000) | 9850 (3000) | 6560 (2000) | 6560 (2000) |

| Wire OD, inch (mm) | 1.8/2,2 | 1.8/2,2 | 1.8/2,2 | 1.8/2,2 |

| Electric motor (power, speed, voltage)* | 1.1 kW, N = 1000rpm, 380V / 220V | 1.1/1.5 kW, N = 1000 rpm, 380V / 220V | 1.1 kW, N = 1000rpm, 380V / 220V | 0.75 kW, N = 1000rpm, 380V / 220V |

| Scraper travel speed, max. without adjustment/ (adjusted by VFD for automatic units) m/min* | 3 – 17 | 3 – 17 | 3 – 17 | 3 – 17 |

| Overall dimensions, inch (mm)* | 2100х560х830 | 2160х680х830 | 750х460х1720 | 750х400х1780 |

| Unit weight without wire / with wire (2 inch) (max.), kg | 190/280 | 200/300 | 90/140 | 80/145 |

| Installation version | At well site | At well site | At wellhead on lubricator | At wellhead on lubricator |

| Operation mode | Manual, semi-automatic / manual, automatic | Manual, semi-automatic / manual, automatic | Manual, automatic | Manual, automatic |

* Provided reference values may vary depending on Customer’s technical requirements.

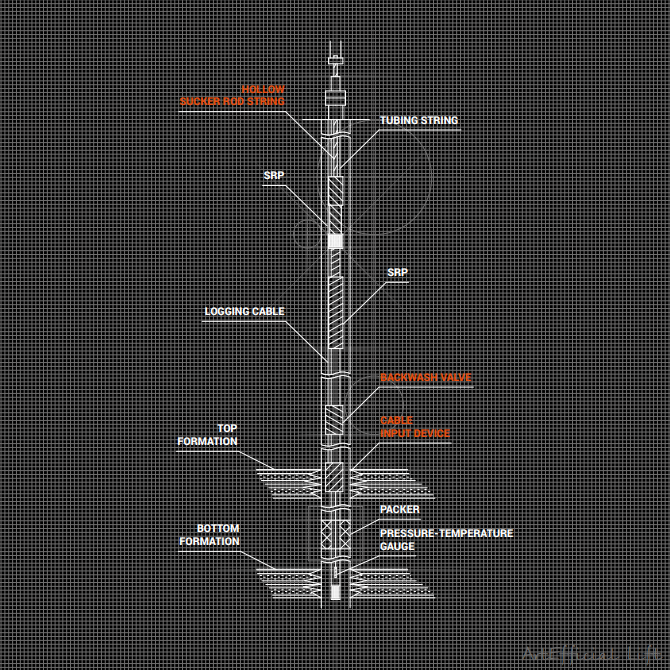

Dual completion SRP-SRP

Application

Simultaneous dual oil production from two formations and separate flow rate metering.

Advantages

- Separate metering of produced fluid;

- Smaller equipment dimensions due to concentric arrangement of production strings;

- Adjustment of well operation modes;

- Bottom formation pressure and temperature measurement;

- Flushing of downhole equipment;

- Injection of reagents to lower formation;

- Separate sampling from each formation without well stop;

Benefits

- Increased oil production by eliminating formations interaction;

- Decreased drilling footage;

- No need to install second surface pumping unit;

- Decreased well start-up time;

- Killing of each formation without packer unset;

- (De-) installation with standard equipment and tools by workover crews;

- Technological service provided by manufacturer: selection, production, installation, supervision and maintenance;

Order reference

DUAL COMPLETION SRP-SRP

Technical specification

- Max. pump setting depth, ft (m):

- 4920 (1500)

- Casing ID, inch (mm):

- not less than 5 (127)

- Tubing OD, inch (mm):

- from 2 7/8 (73)

- Ideal flow rate of two SRPs, bopd (m3 /day):

- up to 520 (83)

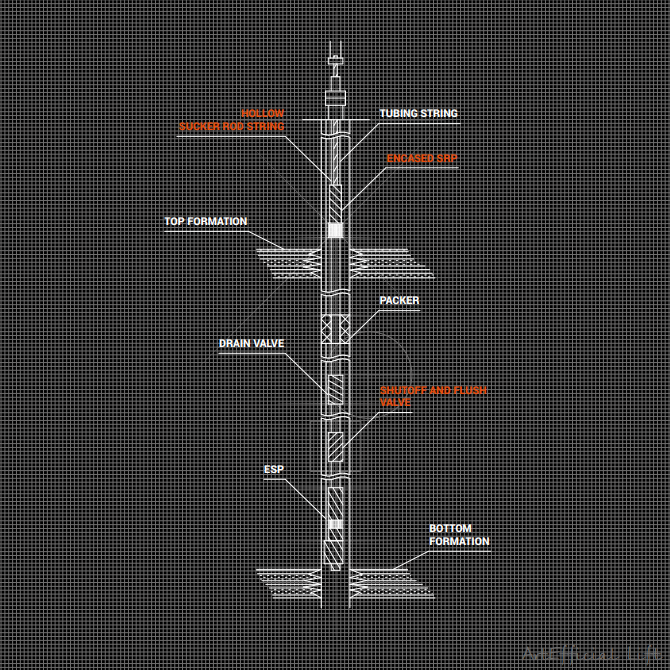

Dual completion ESP-SRP

Application

Simultaneous dual oil production from two formations and separate flow rate metering.

Advantages

- Separate metering of produced fluid;

- Separate adjustment of each pump;

- Smaller equipment dimensions due to concentric arrangement of production strings;

- Separate sampling from each formation without well stop;

Benefits

- Increased oil production by eliminating formations interaction;

- Decreased drilling footage;

- SRP replacement without tubing string rising and packer unset;

- Decreased well start-up time;

- Killing of each formation without packer unset;

- (De-) installation with standard equipment and tools by workover crews;

- Separate drives for each pump to operate in case the other one is idle;

- Technological service provided by manufacturer: selection, production, installation, supervision and maintenance;

Order reference

DUAL COMPLETION ESP-SRP

Technical specification

- Casing ID, inch (mm):

- not less than 5 (127)

- Tubing OD, inch (mm):

- from 2 7/8 (73)

- SRP max. setting depth, ft (m):

- up to 5905 (1800)

- SRP estimated flow rate, bopd (m3 /d):

- up to 345 (55)

- ESP max. setting depth, ft (m):

- up to 11480 (3500)

- ESP estimated flow rate, bopd (m3 /d):

- up to 2200 (350)

Dual completion SRP-ESP

Application

Simultaneous dual oil production from two formations and separate flow rate metering.

Advantages

- Separate metering of produced fluid;

- Separate adjustment of each pump;

- Smaller system dimensions due to concentric arrangement of production strings;

- Separate sampling from each formation without well stop;

Benefits

- Increased oil production by eliminating formations interaction;

- Decreased drilling footage;

- Decreased well start-up time;

- Killing of each formation without packer unset;

- (De-) installation with standard equipment and tools by workover crews;

- Separate drives for each pump to operate in case the other one is idle;

- SRP replacement without tubing string rising and packer unset;

- ESP replacement without packer unset;

- Technological service provided by manufacturer: selection, production, installation, supervision and maintenance;

Order reference

DUAL COMPLETION SRP-ESP

Technical specification

- Casing ID, inch (mm):

- not less than 5 (127)

- Tubing OD, inch (mm):

- from 2 7/8 (73)

- SRP max. setting depth, ft (m):

- up to 5905 (1800)

- SRP estimated flow rate, bopd (m3 /d):

- up to 345 (55)

- ESP max. setting depth, ft (m):

- up to 11480 (3500)

- ESP estimated flow rate, bopd (m3 /d):

- up to 2200 (350)

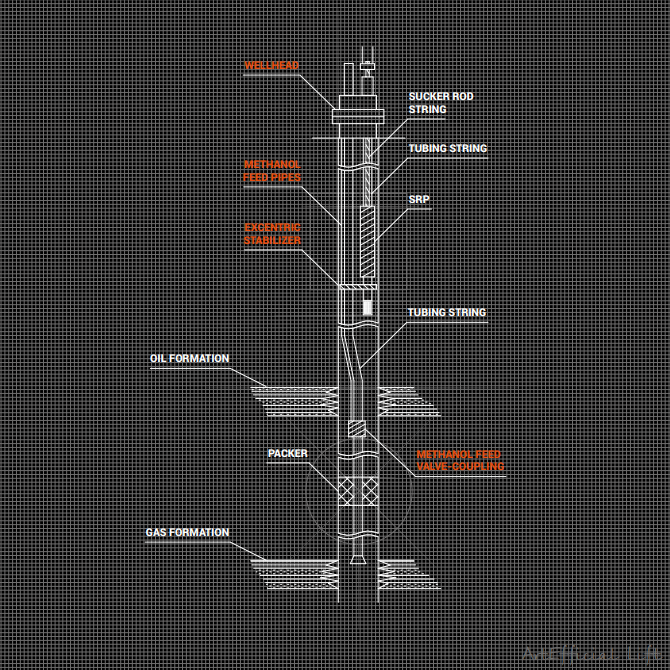

Dual completion GAS-SRP

Application

Dual completion of gas and oil through two parallel production strings.

Advantages

- Separate metering of produced fluid and gas;

- Separate production mode adjustment for each formation;

- Methanol to gas production lift feeding;

Benefits

- Dual completion of oil and gas from single well;

- Decreased drilling footage;

- SRP replacement without packer unset and gas lift rising;

- Double-lift wellhead allowing to explore one formation without stopping another;

- Killing of each formation without packer unset;

- (De-) installation with standard equipment and tools by workover crews;

- Double-lift arrangement for production from one formation when another is stopped;

- Technological service provided by manufacturer: selection, production, installation, supervision and maintenance;

- Package supply of subsurface and surface equipment;

Order reference

DUAL COMPLETION GAS-SRP

Technical specification

- Casing ID, inch (mm):

- not less than 6 5/8 (168)

- Tubing OD, inch (mm):

- from 2 3/8 (60)

- SRP max. setting depth, ft (m):

- up to 9850 (3000)

- SRP estimated flow rate, bopd (m3 /d):

- up to 345 (55)

- Max. gas flow rate, m3 /d:

- up to 100.000

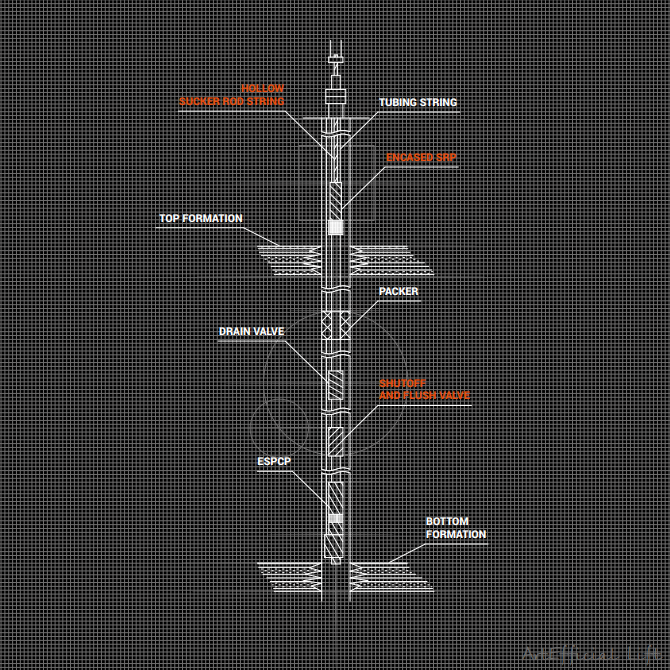

Dual completion ESPCP-SRP

Application

Simultaneous dual oil production from two formations and separate flow rate metering.

Advantages

- Separate metering of produced fluid;

- Separate adjustment of each pump;

- Smaller system dimensions due to concentric arrangement of production strings;

- Separate sampling from each formation without well stop;

Benefits

- Increased oil production by eliminating formations interaction;

- Decreased drilling footage;

- SRP replacement without tubing string rising and packer unset;

- Decreased well start-up time;

- Killing of each formation without packer unset;

- (De-) installation with standard equipment and tools by workover crews;

- Separate drives for each pump to operate in case the other one is idle;

- Technological service provided by manufacturer: selection, production, installation, supervision and maintenance;

Order reference

DUAL COMPLETION ESPCP-SRP

Technical specification

- Casing ID, inch (mm):

- not less than 5 (127)

- Tubing OD, inch (mm):

- from 2 3/8 (60)

- SRP max. setting depth, ft (m):

- up to 5905 (1800)

- SRP estimated flow rate, bopd (m3 /d):

- up to 345 (55)

- ESPCP max. setting depth, ft (m):

- up to 8200 (2500)

- ESPCP estimated flow rate, bopd (m3 /d):

- up to 1885 (300)

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia