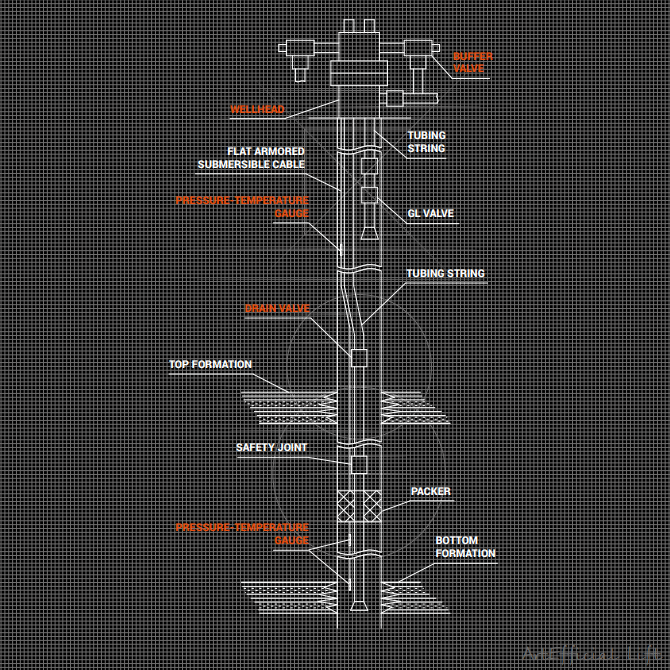

Dual completion natural flow-natural flow

Application

Dual completion of oil through two parallel production strings.

Advantages

- Separate flow rate metering;

- Infinite adjustment of buffer pressure of each formation;

- Each formation pressure and temperature measurement;

- Separate sampling from each formation without well stop;

- Provision of deparaffination unit for each production string;

- Master valves available at wellhead;

- Emergency tubing disconnection from packer-anchor equipment;

Benefits

- Increased oil production by eliminating formations interaction;

- Decreased drilling footage;

- Double-lift wellhead allowing to explore one formation without stopping another;

- Killing of each formation without packer unset;

- (De-) installation with standard equipment and tools by workover crews;

- Double-lift arrangement for production from one formation when the other one is idle;

- Technological service provided by manufacturer: selection, production, installation, supervision and maintenance;

- Package supply of subsurface and surface equipment;

Order reference

DUAL COMPLETION NATURAL FLOW – NATURAL FLOW

Technical specification

- Casing ID, inch (mm):

- not less than 6 5/8 (168)

- Tubing OD, inch (mm):

- from 2 3/8 (60)

- Unit max. setting depth, ft (m):

- up to 14760 (4500)

- Max. pressure, MPa (Psi):

- 21 (3045)

- Type of downhole deparaffination unit:

- automatic, semi-automatic

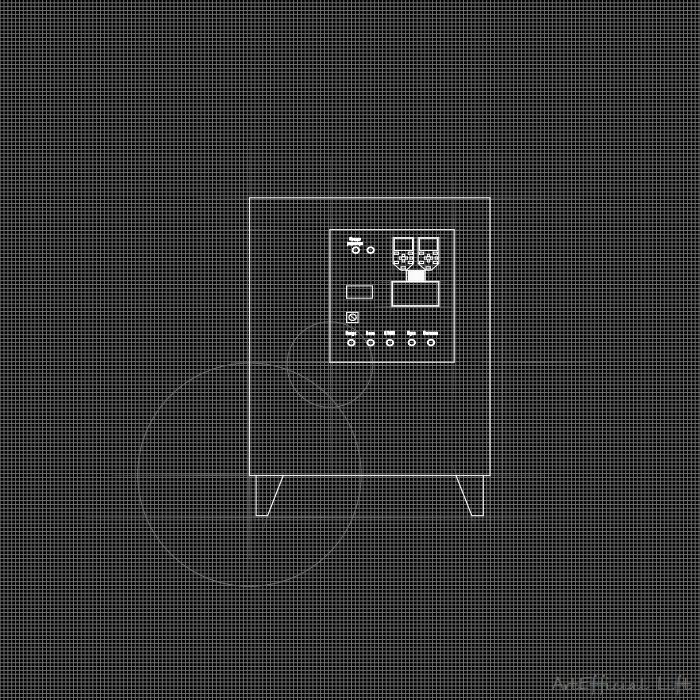

Control box

Application

Automatic protection and speed control of electric motor for enhanced oil production.

Advantages

- High reliability;

- Wide range of customized equipment upgrade options;

- Flexible real-time drive control:

– by pump filling level;

– by calendar;

– by timer;

– by SCADA remote commands;

– in manual mode; - Accurate measurement of load and position of polished rod;

- Unit operation data archiving;

- Remote control, monitoring, reading of dynamograms and emergency notification in real time are available;

- Modifications with ELKAM-RM remote monitoring and control system, additional control sensors, video cameras and other electrical equipment are available;

Benefits

- Optimized and automated production;

- Improved energy efficiency;

- Runlife exceeds 5 years;

Types of control boxes

- Direct start and automatic control;

- VFD with manual and automatic control;

- Sensorless automated control;

- Intelligent control boxes;

Order reference

CONTROL BOX-ELKAM-BPU80*-VFD

*BPU80 – beam pumping unit

Technical specification

- Power, kWt:

- up to 75 (more – as per Customer’s request)

- Protection index IP:

- as per Customer’s request

- Climatic version:

- as per Customer’s request

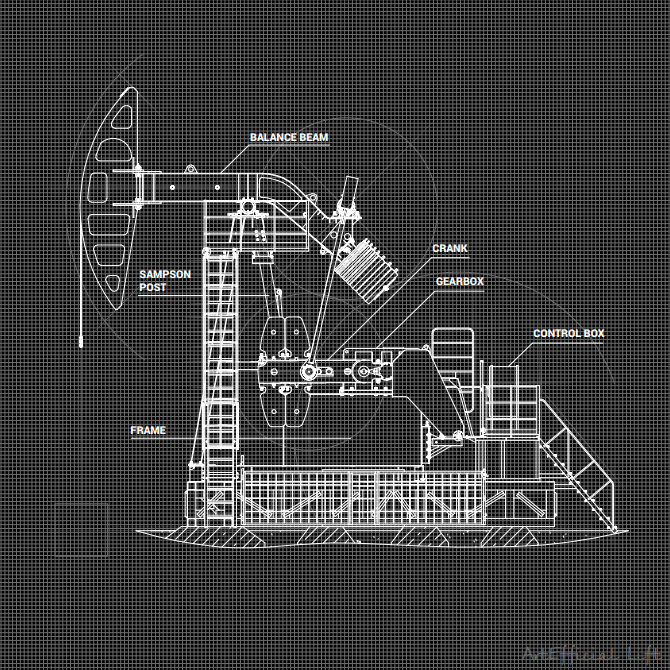

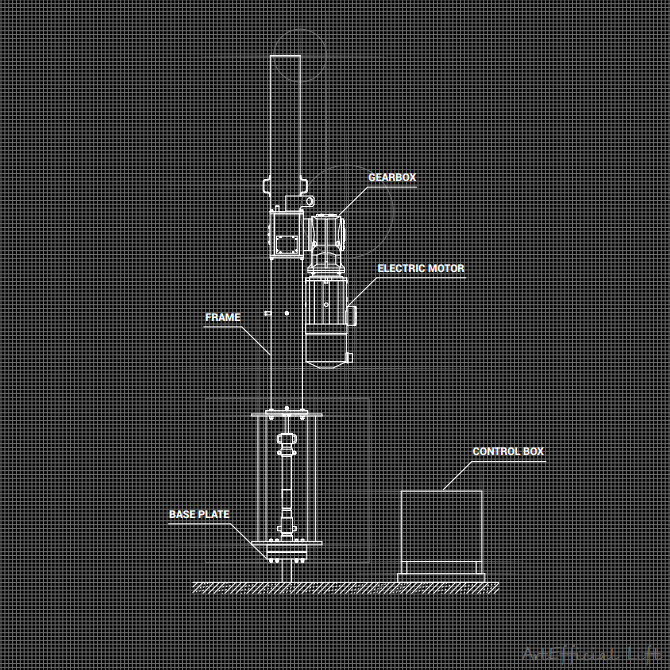

Beam pumping unit

Application

Reciprocal motion transmission to plunger of sucker rod pump.

Advantages

- Serial equipment tested for decades around the world;

- High reliability and efficiency;

- Low energy consumption;

- High maintainability and repairability;

- ELKAM control box is available with remote control, monitoring and real-time display of dynamograms;

Benefits

- Energy saving;

- Service life exceeds 10 years;

- Stable operation throughout the entire runlife;

Order reference

BPU-ELKAM 60

Technical specification

| BPU ELKAM 60 | BPU ELKAM 80 | BPU ELKAM 120 | |

|---|---|---|---|

| Polished rod load, kN (t) | 60 (6) | 80 (8) | 120 (12) |

| Stroke, ft (m) | up to 6 (2.1) | up to 11(3.5) | up to 16 (5) |

| Strokes per minute | up to 10 | up to 10 | up to 5 |

| Engine speed, rpm | 500-750 | 500-750 | 1500 |

| Engine rated power, kW | up to 18 | up to 22 | up to 45 |

| Weight, kg | 8 600 | 12 500 | 24 000 |

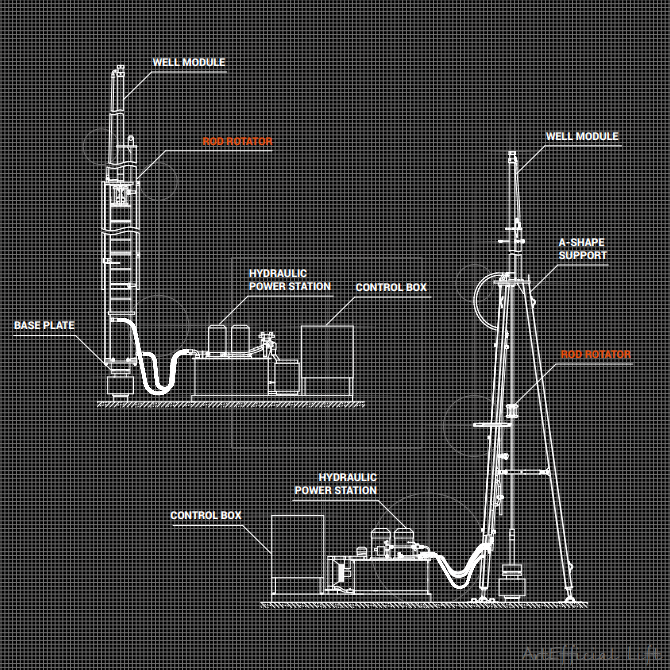

Hydraulic pumping unit

Application

Reciprocal motion transmission to plunger of sucker rod pump.

Advantages

- Easy installation and compact size;

- Low metal consumption;

- No foundation is required;

- Various modifications are available;

- Reduced dynamic loads on rod string due to smooth reverse;

- Rod rotator is available;

- Upstroke / downstroke speed may differ;

- Electro-hydraulic system duplication ensures high reliability;

- Spudding mode (when sucker rod string is clogged);

Benefits

- Remote control, monitoring and real-time display of dynamograms;

- Energy saving;

- Reduced well infrastructure cost;

- Reduced installation time;

- Higher mobility;

- Increased efficiency of pumping system;

- Improved performance in complicated oil production;

Order reference

HPU-120-4

Technical specification

- Polished rod load, kN:

- up to 200

- Stroke length, ft (m):

- up to 20 (6)

- Strokes per minute, 1/min:

- up to 6

- Operating pressure, MPa (Psi):

- up to 19 (2755)

- Control system:

- electronic, VFD

- Polished rod OD, inch (mm):

- 1.25 (32); 1.57 (40)

- Support type:

- base plate, A-shape support

- Modification of well module:

- open/closed, double lift for dual completion

Linear pumping unit

Application

Reciprocal motion transmission to plunger of sucker rod pump.

Advantages

- Remote control and monitoring;

- Smooth regulation of number of strokes;

- No foundation is required;

- Easy (de-) installation;

- Real-time monitoring of pumping unit operation;

- Rod rotator is available;

- Installation on different wellhead setup;

Benefits

- Reduced well infrastructure cost;

- Reduced installation time;

Order reference

LPU-80-1.5

Technical specification

- Polished rod load, kN:

- up to 80

- Stroke length, ft (m):

- 5 (1.5)

- Strokes per minute, 1/min:

- up to 6

- Control system:

- electronic, VFD

- Polished rod OD, inch (mm):

- up to 1.5 (38)

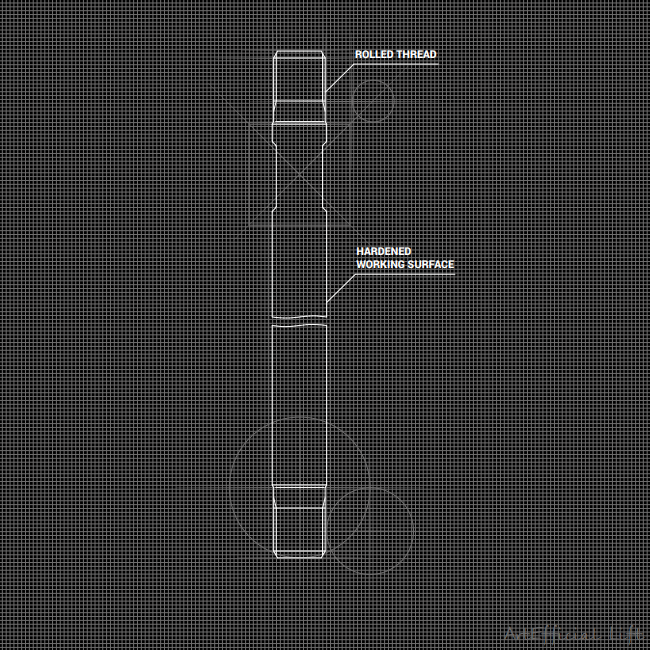

Polished rod

Application

Wellhead sealing, as well as connection of surface drive with sucker rod string and transmission of reciprocal motion to sucker rod pump plunger or transmission of rotary motion to PCP rotor during oil production.

Advantages

- Rolled connection thread for high fatigue strength;

- Rod surface hardening by spinning;

- Improved strength and anti-corrosion properties;

Benefits

Coating and rolled thread ensure extended runlife

Order reference

PR-1.25-7/8-11000-D

Technical specification

- Polished rod OD, inch (mm):

- 0.98 (25); 1.12 (28.6); 1.25 (31.8); 1.5 (38.1)

- Connection thread, inch (mm):

- 3/4 (19), 7/8 (22), 1(25)

- Length, inch (mm):

- up to 435 (11000)

- Grade:

- K, C, D, D special

- Сoating:

- nitrided / spray metal / plain

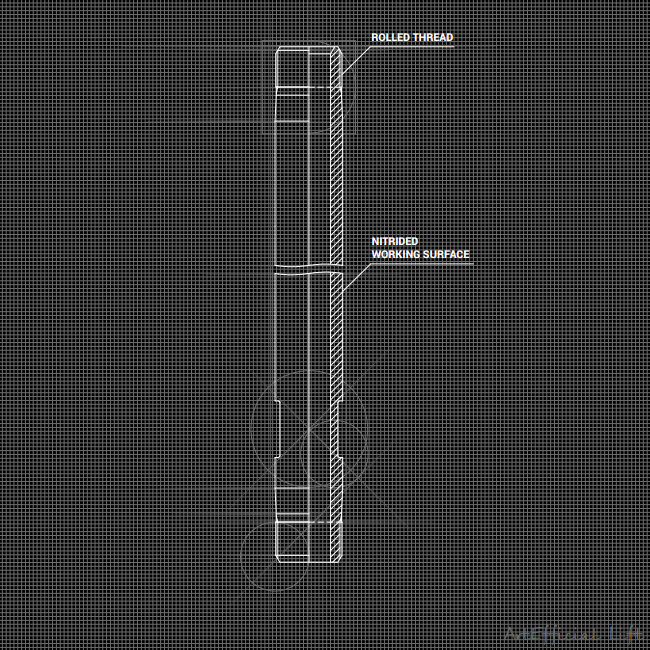

Hollow polished rod

Application

- Wellhead sealing;

- Transmission of reciprocal motion from surface drive to sucker rod pump plunger;

- Extraction of produced fluid from pump to production line through inner channel;

- Hollow sucker rod and tubing string washing in order to remove paraffin and salt deposits and to improve efficiency of equipment set;

- Injection of chemical agents or steam into well through hollow sucker rod string to reduce effects of complicating factors and to enhance oil recovery;

Advantages

- Rolled connection thread for high fatigue strength;

- Thrust cones reduce bending stress at threads and ensures tight connection;

- Nitrided hardening of outer surface;

Benefits

- Coating and rolled thread ensure extended runlife;

- Separate lifting of produced fluid at dual completion and injection;

Order reference

HPR-42-4880-D

Technical specification

- Nominal size:

- 42, 44

- Diameter, inch (mm):

- 1.65 (42); 1.73 (44)

- Length, inch (mm):

- 155 (3890), 190 (4880), 315 ( 8000)

- Grade:

- C, D

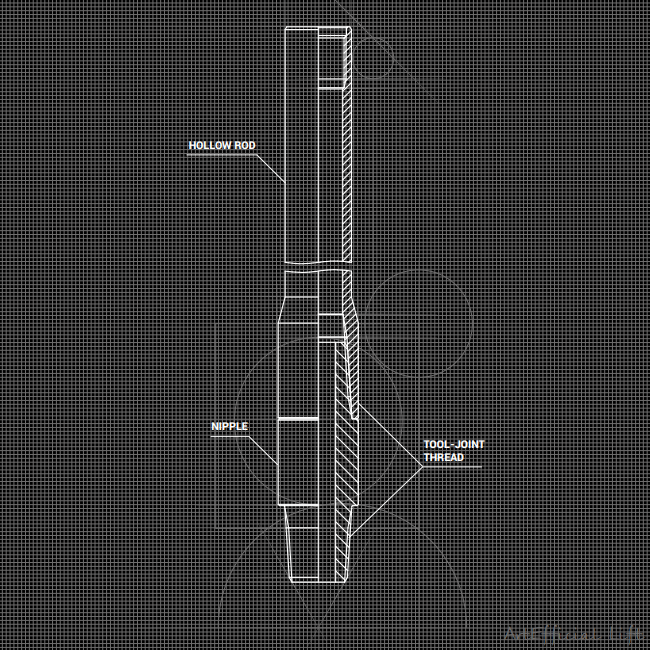

PCP hollow polished rod

Application

- Wellhead sealing;

- Transmission of torque from a surface drive to PCP rotor;

- Hollow sucker rod and tubing string washing in order to remove paraffin and salt deposits and to improve efficiency of system;

- Can be used for reciprocal motion from surface drive to plunger of sucker rod pump;

Advantages

- Hot-upset rod head ensures equal strength across polished rod;

- Tool-joint threads are used for transmission of high torques and ensure reliability and tightness of connections at bending stress and tensile loading;

Benefits

- Tubing string can be flushed with idle drive without affecting formation zone;

- Minimum volume of flush agents;

- Rod length allows to extract rotor from stator for direct flushing without wellhead disassembly;

Order reference

PCP HPR-38-8000-D

Technical specification

- Nominal size:

- 38

- Diameter, inch (mm):

- 1.5 (38.1)

- Length, inch (mm):

- 315 (8000)

- Grade:

- C, D

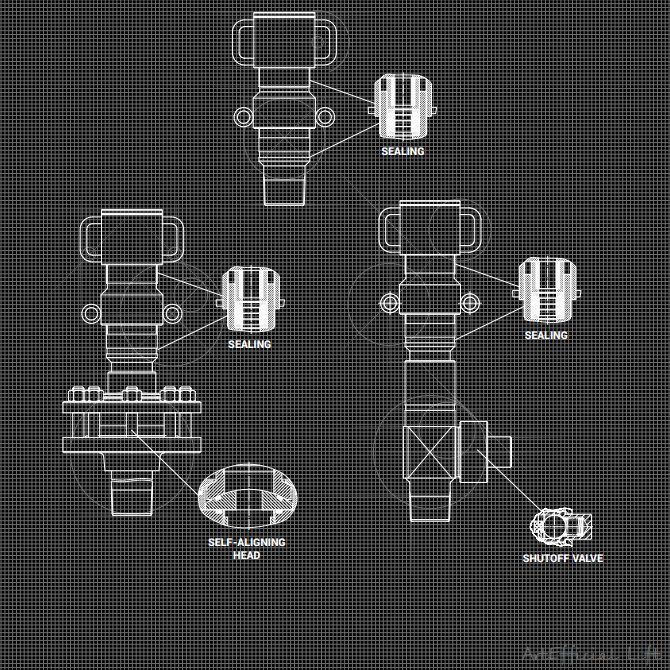

Stuffing box

Application

Sealing of polished rod in wellhead setup during oil production using SRP.

Advantages

- Double sealing allows to replace cups and repair stuffing box without well killing;

- Corrosion- and temperature-resistant modifications;

- Modification with shutoff valve to prevent wellhead depressurization;

- Self-aligning head is available to reduce wear of cups and increase stuffing box runlife;

Benefits

- Improved SRP non-stop operation;

- Elimination of wellhead depressurization;

Order reference

SB-25-32-14

25 (2 7/8”) – tubing ID

32 (1.25) – polished rod OD

14 – working pressure with idle BPU

Technical specification

- Operating pressure with running BPU, MPa (Psi):

- 4 (580)

- Operating pressure with idle BPU, MPa (Psi):

- 14 (2030); 21 (3045)

- Polished rod OD, inch (mm):

- 1.25 (32); 1.5 (38); 1.65 (42)

- Radial movement of stuffing box axis, inch (mm):

- 0.47 (12)

- Stuffing box tilt angle (taking into account radial movement), degree:

- 5

- Temperature properties, °F (°C):

- -140 up to +572 (-60 up to +300)

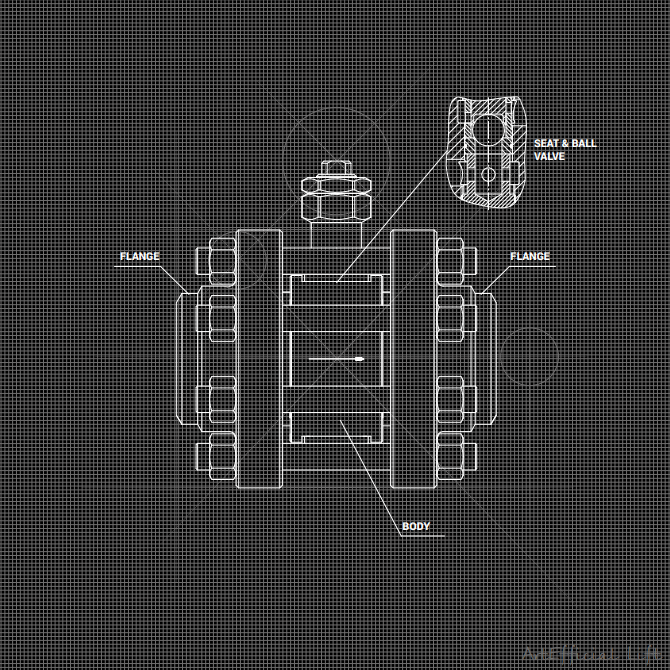

Bypass check valve

Application

Gas bypass from annulus to production line.

Advantages

- Easy to install;

- High repairability;

- High reliability;

- Corrosion-resistant modification is available;

Benefits

- Low maintenance cost;

- Normalization of well operation due to maintenance of constant annular pressure;

Order reference

BCV-65**х21*

Technical specification

- Operating pressure*, MPa (Psi):

- up to 21 (3045)

- Nominal pipe size**, inch (mm):

- 2.5 (65)

- Flow rate, bopd (m3 /d):

- up to 25160 (4000)

- Connection flanges:

- up to Customer’s requirements

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia