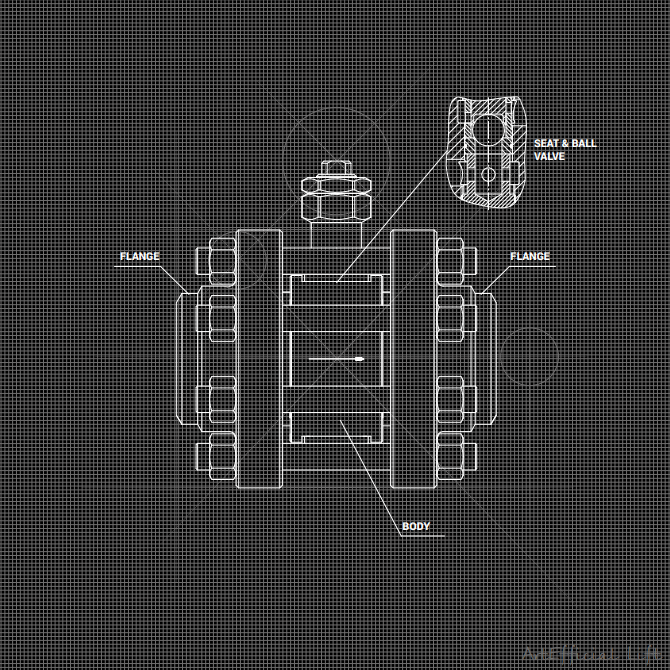

Bypass check valve

Application

Gas bypass from annulus to production line.

Advantages

- Easy to install;

- High repairability;

- High reliability;

- Corrosion-resistant modification is available;

Benefits

- Low maintenance cost;

- Normalization of well operation due to maintenance of constant annular pressure;

Order reference

BCV-65**х21*

Technical specification

- Operating pressure*, MPa (Psi):

- up to 21 (3045)

- Nominal pipe size**, inch (mm):

- 2.5 (65)

- Flow rate, bopd (m3 /d):

- up to 25160 (4000)

- Connection flanges:

- up to Customer’s requirements

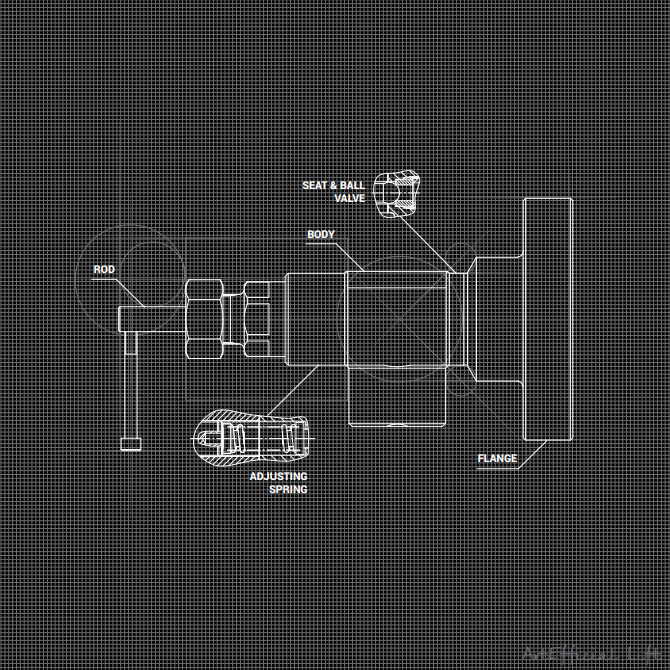

Buffer valve

Application

Produced fluid flow control during ESP operation and natural flow.

Advantages

- Easy wide-range flow control;

- Prevention of backflow in tubing string after pump stop;

Benefits

- ESP operation mode optimization during run-in-hole;

- Stable well performance;

- Fluid flow control;

Order reference

BV-65х21-10

65х21 – connection size

10 – valve actuation pressure

Technical specification

- Production method:

- ESP, natural flow

- Nominal pipe size, inch (mm):

- 2.5 (65)

- Valve actuation pressure, MPa (Psi):

- up to 21 (3045)

- Operating pressure, MPa (Psi):

- up to 35 (5075)

- Flow rate, bopd (m3 /d):

- up to 3144 (500)

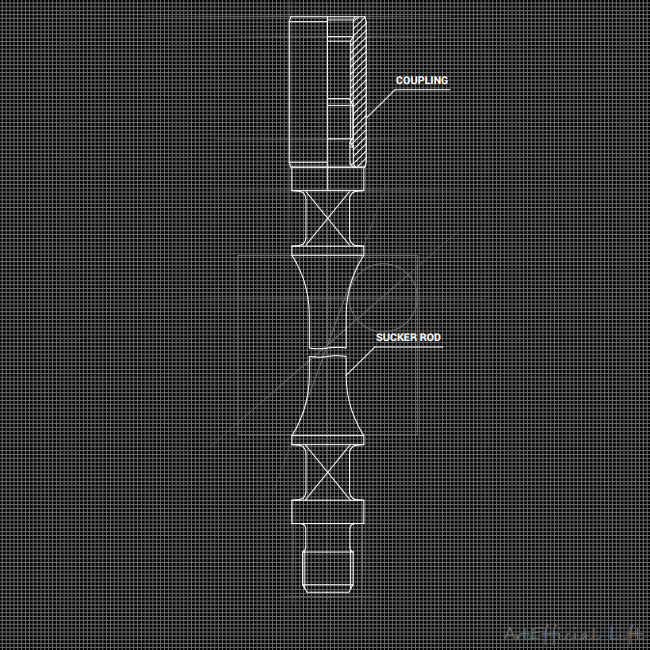

Conventional sucker rod

Application

Solid sucker rods are designed for transmission of reciprocal motion from surface drive to sucker rod pump plunger or torque to PCP rotor in the process of oil production.

Advantages

- Heat-treated sucker rod body;

- Improved strength and anti-corrosion characteristics;

- Clip-on and moulded high-strength polyamide centralizers are available;

- Rolled pin thread;

Benefits

- Runlife is over 5.5 years;

- MTBF is 5 million cycles;

- Failure-free durable thread;

Order reference

SR-7/8-8000-D

Technical specification

- Applicable standards:

- API 11B

- Nominal size, inch (mm):

- 3/4 (19), 7/8 (22), 1(25)

- Length, inch (mm):

- 20-315 (500-8000)

- Grade:

- K, C, D, D-special

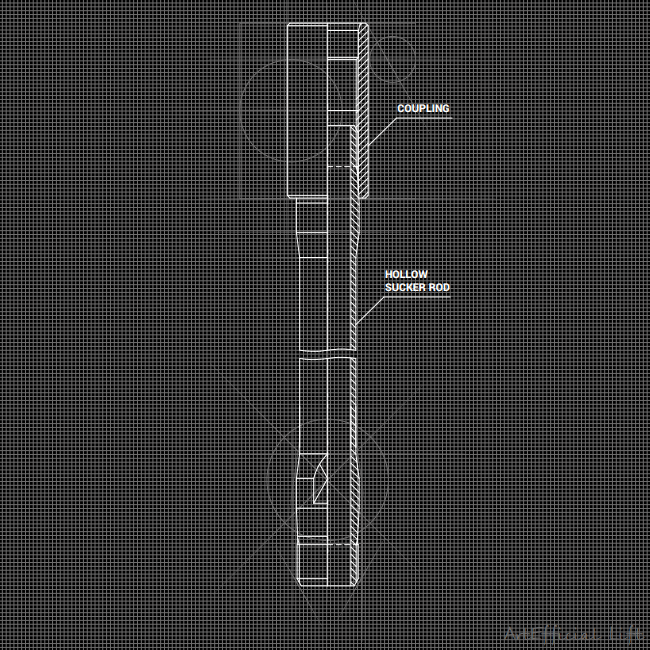

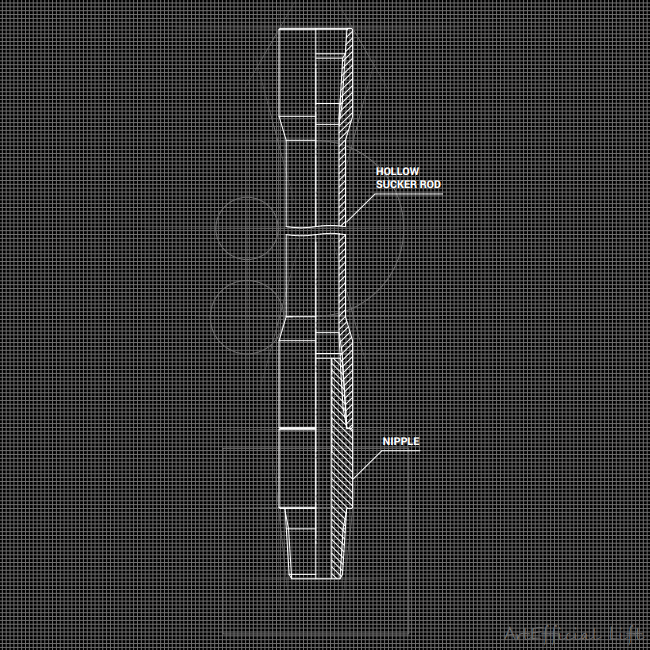

Hollow sucker rod

Application

- Transmission of reciprocal motion from surface drive to sucker rod pump plunger;

- Extraction of produced fluid from pump to wellhead through inner channel;

- Hollow sucker rod and tubing string washing in order to remove paraffin and salt deposits and to improve equipment operation efficiency;

- Injection of chemical agents or steam into tubing string or bottom-hole formation zone to reduce effects of complicating factors and to improve oil production;

Advantages

- Hollow sucker rods are made of strengthened heat-treated cold-rolled pipes;

- Hot-upset head ensures equally efficient cross-section of sucker rod and equal inner diameter of channel along entire length;

- Rolled connection threads ensure high fatigue strength;

- Thrust cones reduces flexural stress at threads and ensures tight connection;

- Moulded guides are available;

Benefits

- Separate lifting of produced fluid in dual completion & injection equipment sets;

- Subsurface equipment smaller dimensions due to concentric arrangement of lifts;

- Decrease metal consumption by using hollow sucker rods without tubing string;

- Higher fluid velocity reduces deposits of paraffin and salt;

Order reference

HSR-1-8000-D

Technical specification

- Nominal size, inch:

- HSR 19, HSR 22, HSR 25

- Sucker rod body diameter, inch (mm):

- 1.3 (34), 1.45 (37), 1.49 (38)

- Sucker rod ID, inch (mm):

- 1.1 (28)

- Coupling OD, inch (mm):

- 1.9 (49), 2.1 (54)

- Length, inch (mm):

- 17 – 315 (450-8000)

- Strength grade:

- С, D

- Production flow rate, bopd (m 3 /d):

- up to 440 (70)

- Injection flow rate, bopd (m 3 /d):

- up to 880 (140)

PCP hollow sucker rod

Application

- Transmission of torque from surface drive to PCP rotor;

- Tubing string washing to remove paraffin and salt deposits and to improve equipment operation efficiency;

- PCP hollow sucker rod can be used as a component of sucker rod string to transmit reciprocal motion from surface drive to sucker rod pump;

Advantages

- PCP hollow sucker rods are made of strengthened heat-treated cold-rolled pipes;

- Hot-upset head ensures equal strength across the sucker rod;

- Tool-joint threads are used for transmission of high torques and ensure reliability and tightness of connections in flexural stress and tensile load;

- String is easy to assemble and disassemble;

- Moulded guides are available;

- Coupling-free connection;

Benefits

- Increased torque transmission;

- Longer runlife of sucker rod string;

- Tubing string can be flushed with drive stopped in order to neutralize effects on formation zone;

- Higher durability of threaded connections;

- Minimum volume of flush agents;

- Reduced time of RIH/POOH operations.;

Order reference

HSR-PCP-7/8-8000-D

Technical specification

- Nominal size, inch:

- HSR-PCP 7/8

- Sucker rod body diameter, inch (mm):

- 1.45 (37)

- Sucker rod ID, inch (mm):

- 1.14 (29)

- Upset head OD, inch (mm):

- 1.8 (46)

- Nipple ID, inch (mm):

- 0.78 (20)

- Length, inch (mm):

- 17 – 315 (450 -8000)

- Max. torque, lb·ft (kgf·m):

- 2025 (280)

- Strength grade:

- С, D

- Connection thread:

- NC13

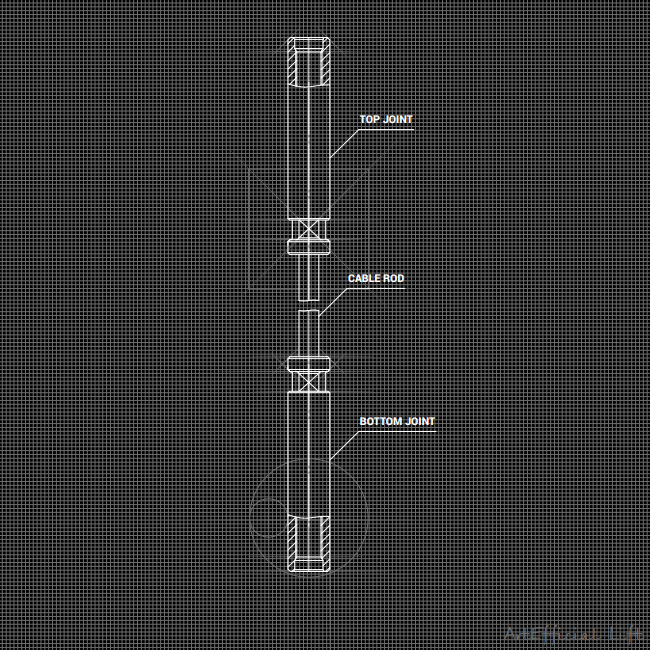

Flexible cable rod

Application

Flexible cable rod is used as component of sucker rod string at place of sidetracking and within deviated sections of borehole.

Advantages

- Coupling-free;

- Corrosion-resistant modification;

- High strength;

- Cable braiding substantially reduces friction against tubing string inner surface;

Benefits

- Substantial reduction in damage of tubing string ensured by larger area of contact between the cable rod and tubing inner surface and by lower friction force;

- Longer well MTBF;

- Higher efficiency of well equipment set ensured by setting sucker rod pump in sidetracks;

- Reduced time of RIH/POOH;

Order reference

FCR- 7/8″/ 3/4″-300

7/8” – top connection thread

3/4” – bottom connection thread

300 – cable rod length (m)

Technical specification

- Min. tubing ID, inch (mm):

- from 2 3/8 (60)

- Cable rod connection thread, inch (mm):

- 3/4 (19), 7/8 (22), 1(25)

- Cable OD, inch (mm):

- 0.78 (20)

- Cable rod length, ft (m):

- up to 3280 (1000)

- Reduced cable stress, MPa (Psi):

- 170 (24655)

- Cable breaking load, kN:

- 370

- Linear meter mass, lb (kg):

- 5.3 (2.4)

Flexible cable rod is used in combination with sucker rod pivot couplings in order to prevent cable twisting.

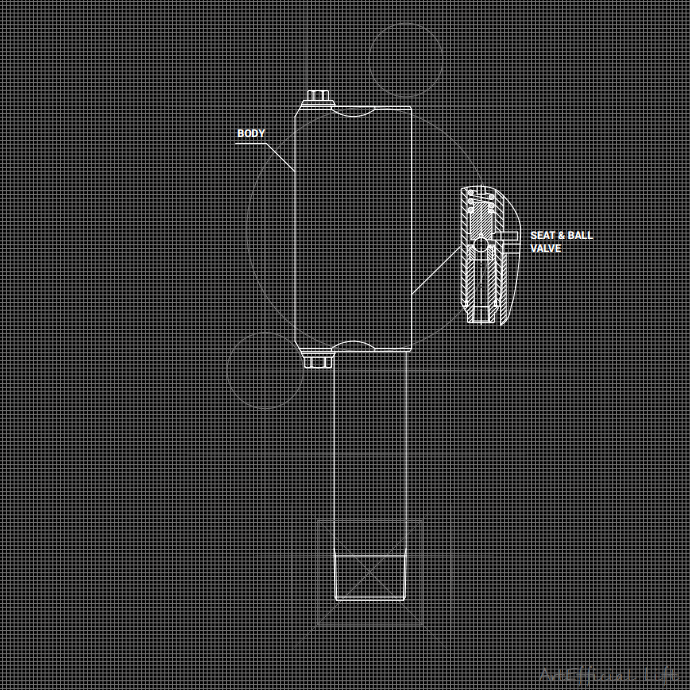

Backwash valve

Application

Backwash valve is designed to backwash tubing from deposits.

Advantages

- Backwashing of bottom pump in dual completion system;

- Full bore;

- Multiple use;

Benefits

- Tubing string can be backwashed bypassing the pump;

- Longer runlife of downhole equipment;

- Higher efficiency of system;

Order reference

BV-73-2

25 (2 7/8”) – tubing ID

Technical specification

- Pump type:

- ESP, PCP, ESPCP, SRP

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Casing ID, inch (mm):

- from 5 1/2 (140)

- Bore diameter:

- according to diameter of tubing used

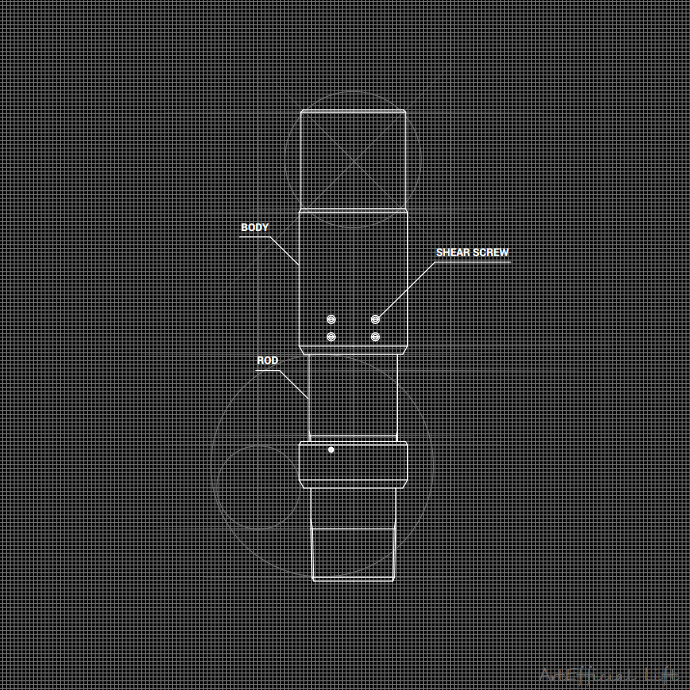

Drain valve with shear screws

Application

Drain valve is designed for tubing string fluid drainage during pull-out operations.

Advantages

- Operating pressure is adjusted by quantity of shear screws;

- Multi-pump application;

- Valve is actuated by excessive pressure in tubing string;

- Actuating pressure can be preset at well site before installation;

- High repairability;

Benefits

Prevents oil spills during pull-out operations.

Order reference

DVSS-25-20

25 (2 7/8”) – tubing ID

20 – valve actuation pressure drop

Technical specification

- Pump type:

- ESP, PCP, ESPCP, SRP

- Casing ID, inch (mm):

- from 4 1/2 (114)

- Valve actuation pressure drop, MPa (Psi):

- 4 – 38 (580-5510)

- Bore diameter, inch (mm):

- 2.4 (62)

- Tubing ID, inch (mm):

- from 2 3/8 (60)

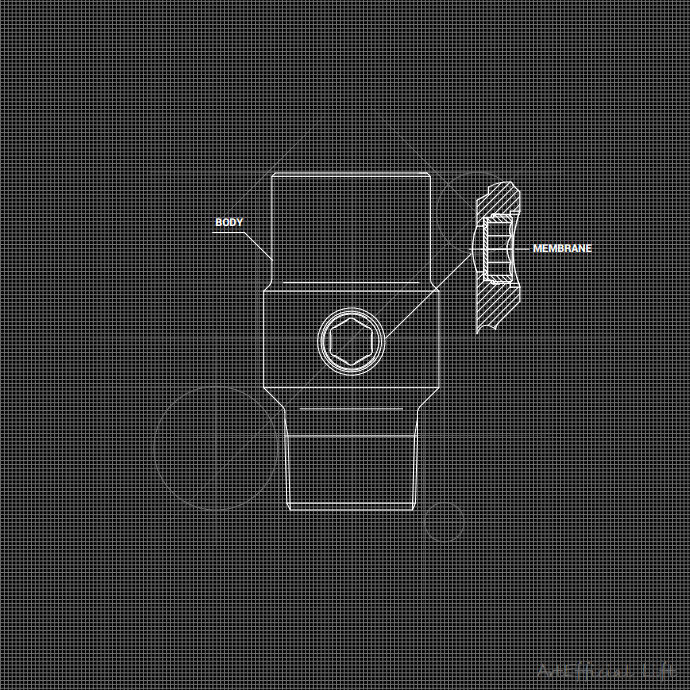

Membrane drain valve

Application

Drain valve is designed for tubing string fluid drainage during pull-out operations.

Advantages

- Quick & easy membrane replacement;

- Adjustable membrane burst pressure;

- Multi-pump application;

- Valve is actuated by excessive pressure in tubing string;

Benefits

Prevents oil spills during pull-out operations.

Order reference

MDV-25-4

25 (2 7/8”) – tubing ID

4 – valve actuation pressure drop

Technical specification

- Pump type:

- ESP, PCP, ESPCP, SRP

- Valve actuation pressure drop, MPa (Psi):

- 2 – 35 (290-5075)

- Casing ID, inch (mm):

- from 4 1/2 (114)

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Bore diameter:

- equal to current tubing ID

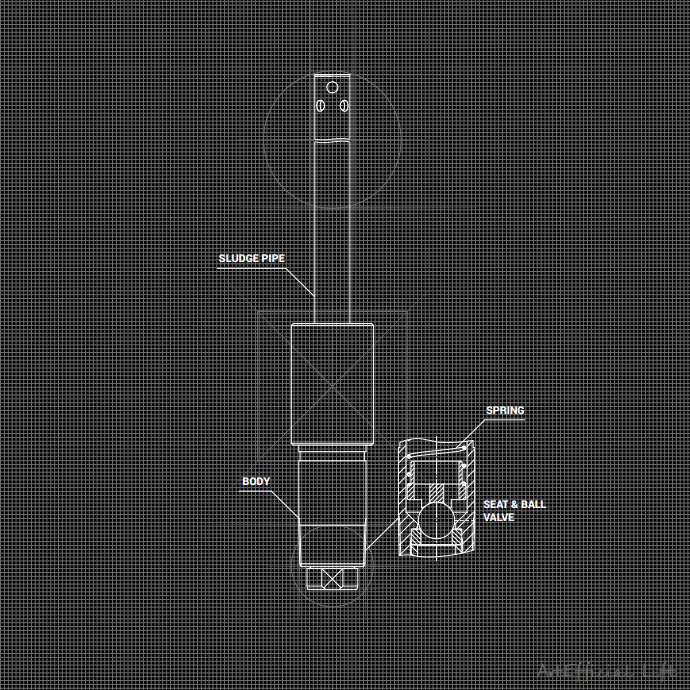

Check valve

Application

Valve secures fluid column in tubing string and prevents pump clogging with solids during shutdown.

Advantages

- Spring ensures valve closure in deviated wells;

- Sludge pipe prevents penetration of solids and scale into the valve;

- High repairability;

Benefits

- Valve prevents reverse rotation of ESP during shutdown;

- Longer pump runlife;

- Easy pump start and commissioning;

- Reduced power consumption when re-starting.

Order reference

CV-25-250

25 (2 7/8”) – tubing ID

250 (1570) – flow rate, m3

/d (bopd)

Technical specification

- Pump type:

- ESP, ESPCP

- Tubing diameter, inch (mm)

- from 2 3/8 (60)

- Casing ID, inch (mm):

- from 4 (102)

- Flow rate, bopd (m3 /d):

- up to 6290 (1000)

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia