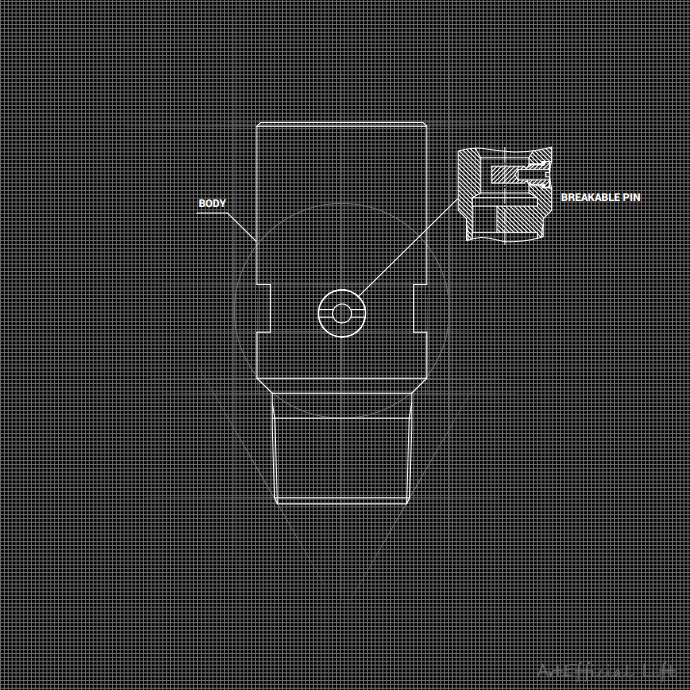

Drain valve with breakable pin

Application

Fluid drain from tubing string during pull-out operations.

Advantages

- In-the-field replacement of breakable pin is available;

- Valve operation doesn’t depend on tubing or annular pressure;

- Valve is opened by steel bar dropped into tubing string;

- Valve is equipped with catcher which prevents penetration of steel bar into pump;

Benefits

Valve helps to prevent oil spills during pull-out operations.

Order reference

DVBP-25

25 (2 7/8”) – tubing ID

Technical specification

- Pump type:

- ESP, ESPCP

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Casing ID, inch (mm):

- from 4 (102)

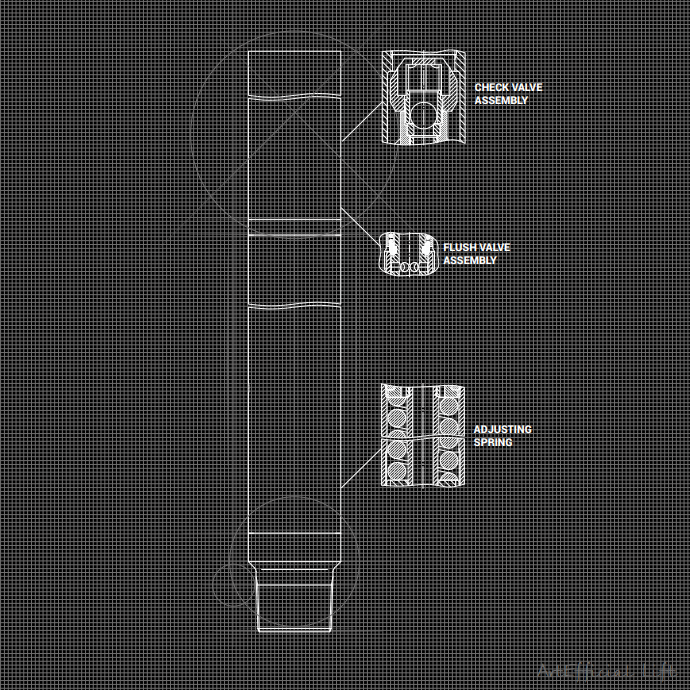

Shutoff and flush valve

Application

Valve holds fluid column in tubing string, prevents pump clogging with solids during well stop and provides direct washing of ESP operating components.

Advantages

- ESP direct washing;

- Wide range of valve opening pressure values for direct washing;

- Multiple use of valve within 1 RIH/POOH operation;

Benefits

- Valve prevents backspin of ESP during well stop;

- Longer runlife;

- Easy pump start & commissioning;

- Reduced power consumption in re-starting;

- Reduced workover cost;

Order reference

SFV-25-15

25 (2 7/8”) – tubing ID

15 – valve opening pressure

Technical specification

- Pump type:

- ESP

- Tubing ID, inch (mm):

- from 2 7/8 (73)

- Casing ID, inch (mm):

- from 4 1/2 (114)

- Valve opening pressure, MPa (Psi):

- 3 – 37 (435-5365)

- Washing mode flow rate, bopd (m3 /d):

- up to 1885 (300)

- Production mode flow rate, bopd (m3 /d):

- up to 3144 (500)

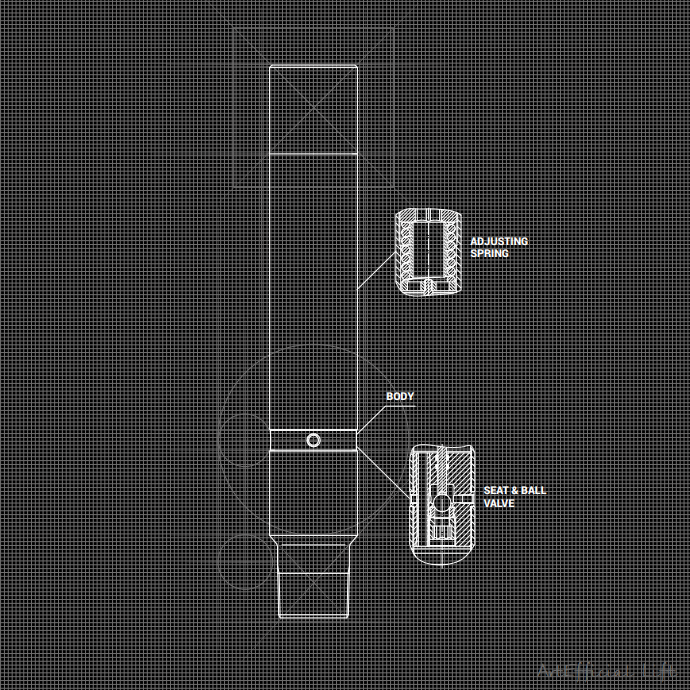

Direct wash valve

Application

Valve is designed for direct washing of tubing string to remove paraffin deposits and for injection of process fluid to kill formations separated by packer.

Advantages

- Direct washing of tubing string without penetration of washing fluid into pump;

- Well killing without packer deinstallation;

- Adjustable valve opening pressure;

- Valve can be used with ESPCP;

Benefits

- Reduction of washing fluid consumption;

- Reduction of washing time;

- Workover cost reduction;

Order reference

DWV-25-18

25 (2 7/8”) – tubing ID

18 – valve opening pressure

Technical specification

- Pump type:

- ESP, ESPCP

- Tubing ID, inch (mm):

- from 2 7/8 (73)

- Casing ID, inch (mm):

- from 4 1/2 (114)

- Valve opening pressure, MPa (Psi):

- 15 – 18 (2175-2610)

- Washing mode flow rate, bopd (m3 /d):

- up to 725 (115)

- Production mode flow rate, bopd (m3 /d):

- up to 2200 (350)

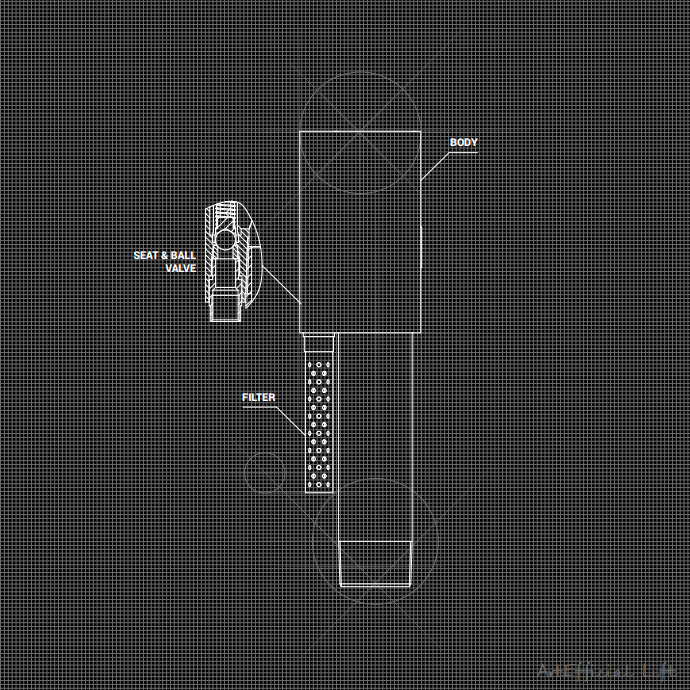

Bypass gas valve

Application

Discharge of excessive gas pressure from annular space into tubing production line.

Advantages

- Valve is installed on tubing string that prevents it from freezing;

- No maintenance is required during operation;

- Full bore;

- Multi-purpose (can be used with any pump type);

Benefits

- No maintenance cost;

- Normalization of well operation due to maintanance of constant annular pressure;

- High repairability;

Order reference

BGV-25

25 (2 7/8”) – tubing ID

Technical specification

- Pump type:

- ESP, PCP, ESPCP, SRP

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Casing ID, inch (mm):

- from 4 1/2 (114)

- Bore diameter:

- equal to current tubing ID

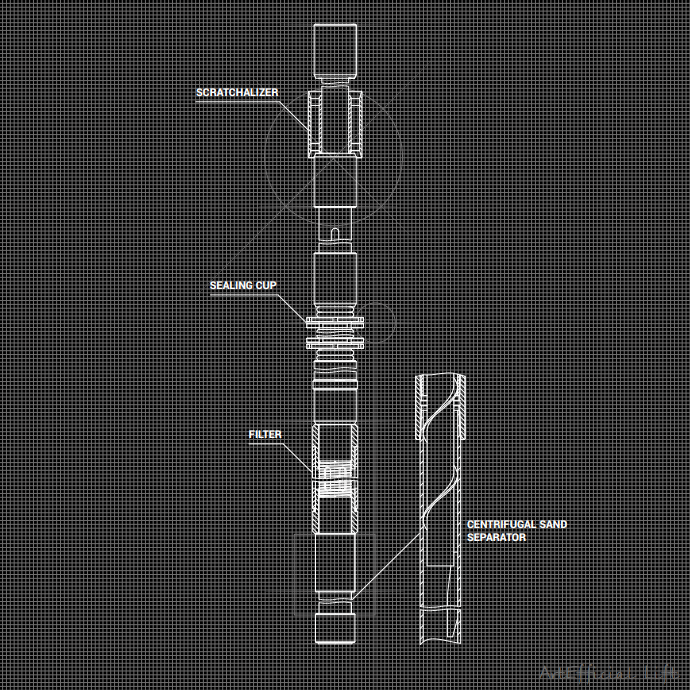

Sand-gas anchor

Application

Sand-gas anchor is used to neutralize or substantially reduce negative effects of solids and gas penetrating into operating parts of pumps and surface equipment.

Advantages

- High separation coefficient – up to 95%;

- Adjustable sand trap length – 33-330 ft (10-100 m);

- Sealing cup prevents overloading of workover rig during RIH/POOH operations;

Benefits

- Prevents early wear of downhole equipment;

- Reduced risk of failure caused by pump clogging;

- Longer runlife of ESPCP;

- Workover cost reduction;

Order reference

25-PG-ESP -146/8

25 (2 7/8”) – tubing ID

146 (5 3/4”) – casing ID

8 (0.31”) – casing wall thickness

Technical specification

- Pump type:

- ESP, ESPCP

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Casing ID, inch (mm):

- 5 1/2 (140), 5 3/4 (146), 6 5/8 (168), 7 (178)

- Flow rate, bopd (m3 /d):

- up to 3144 (500)

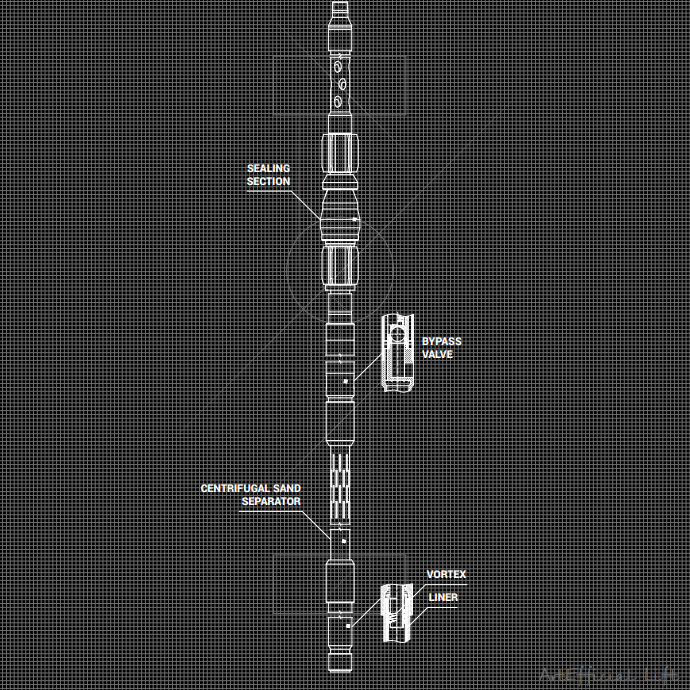

Sand anchor with bypass valve

Application

Sand anchor neutralizes or substantially reduces negative effects of solids penetrating operating components of pumping and surface equipment.

Advantages

- High separation coefficient – up to 95%;

- Adjustable sand trap length– 33-330 ft (10-100 m);

- Bypass valve prevents pump gas lock if sand trap is full;

- Corrosion-resistant steel liner protects separator body from abrasive wear;

- Sealing section tightly fits casing and shuts off annular space;

Benefits

- Prevents early wear of downhole pumping equipment;

- Reduced risk of failure of downhole pumping equipment caused by pump clogging;

- Longer runlife of pumping equipment;

- Reduced well repair cost;

- Higher efficiency of pumping equipment;

Order reference

25-PGB-ESP-168/9

25 (2 7/8”) – tubing ID

168 (6 5/8”) – casing ID

9 (0.35”) – casing wall thickness

Technical specification

- Pump type:

- ESP, PCP, ESPCP, SRP

- Casing ID, inch (mm):

- 5 3/4 (146), 6 5/8 (168), 7 (178)

- Anchor setting angle, degree:

- up to 55

- Flow rate, bopd (m3 /d):

- up to 3144 (500)

- Pressure drop to open bypass valve, MPa (Psi):

- 0.2 (2)

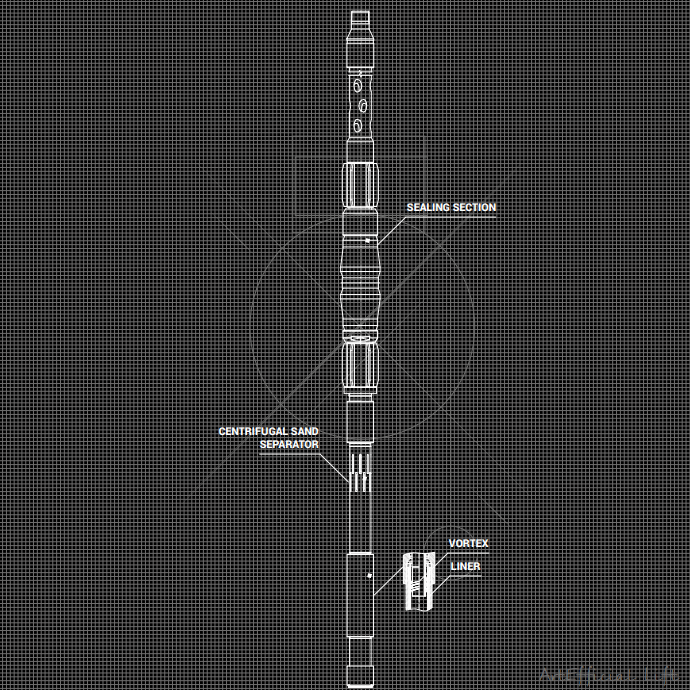

Hydrocyclone separator

Application

Hydrocyclone separator is designed to neutralize or substantially reduce negative effects of solids penetrating into operating parts of pumping system and surface equipment.

Advantages

- High separation coefficient – up to 95%

- Adjustable sand trap length – 33-330 ft (10-100 m);

- Bypass valve prevents pump gas lock if sand trap is full;

- Corrosion-resistant steel liner protects separator body from abrasive wear;

- Sealing section tightly fits casing and shuts off annular space;

Benefits

- Prevents early wear of downhole pumping equipment;

- Reduced risk of failure of downhole pumping equipment caused by pump clogging;

- Longer runlife of pumping equipment;

- Reduced well repair cost;

- Higher efficiency of pumping equipment.;

Order reference

20-CYCLONE-ESP-146/8

20 (2 3/8”) – tubing ID

146 (5 3/4”) – casing ID

9 (0.35”) – casing wall thickness

Technical specification

- Pump type:

- ESP, PCP, ESPCP, SRP

- Casing ID, inch (mm):

- 5 3/4 (146), 6 5/8 (168), 7 (178)

- Anchor setting angle, degree:

- up to 55

- Flow rate, bopd (m3 /d):

- up to 3144 (500)

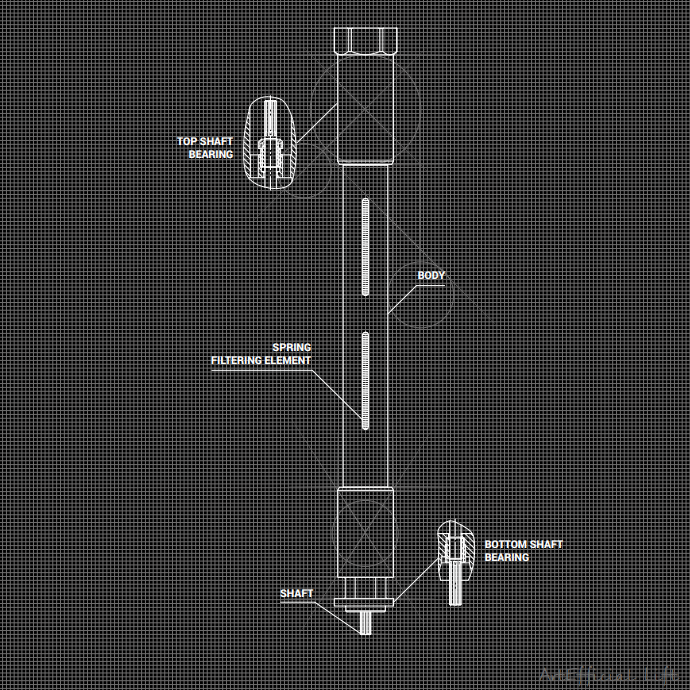

Sand screen filter adjustable

Application

Adjustable sand screen filter is designed to prevent penetration of solids into ESP pumps from intake and to reduce wear of operating pump parts.

Advantages

- Adjustable turn-to-turn clearance – 0.0039-0.039 inch (0.1-1 mm) – to adjust filtration capacity;

- Cascade connection of several sections;

- Self-cleaning spring filtering element;

Benefits

- Prevents early wear of downhole pumping equipment;

- Reduced risk of failure of downhole pumping equipment caused by pump clogging;

- Longer runlife of ESP;

- Reduced ESP repair cost;

Order reference

SSFA-ESP

Technical specification

- Shaft connection size:

- on Customer’s order

- Turn-to-turn clearance, inch (mm):

- 0.0039-0.039 inch (0.1-1 mm)

- Separation coefficient, %:

- up to 95

- Flow rate, bopd (m3 /d):

- up to 3520 (560)

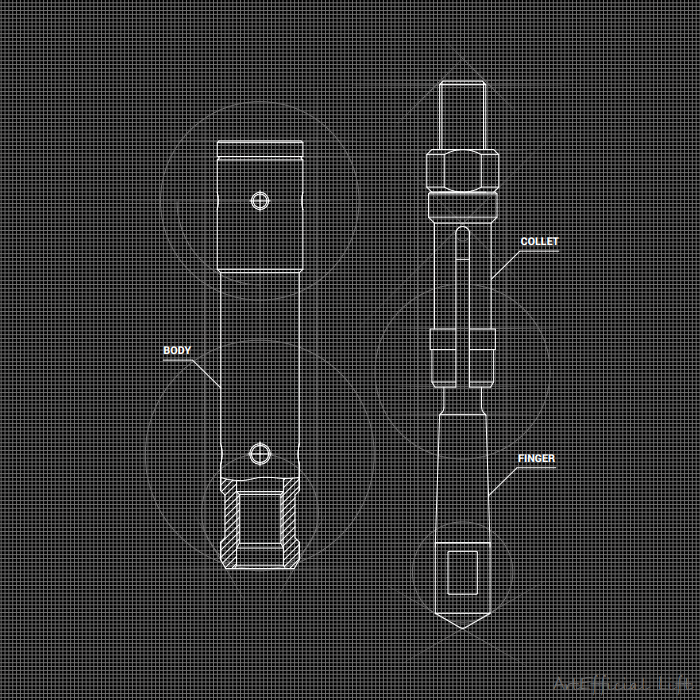

On-tool

Application

Connection of SRP plunger and sucker rod string when running barrel-plunger pair in the hole.

Advantages

- Automatic on-tool prevents penetration of solids into the

sub-plunger space in the process of running pump in well; - Automatic on-tool is designed to prevent damaging

of plunger in tubing string while pump run in hole; - Easier plunger fitting into barrel;

Benefits

High reliability of sucker rod pumping system.

Order reference

ON-TOOL- 20-3/4″ SR

20 (2 3/8”) – tubing ID

3/4” SR – connection thread of sucker rods

Technical specification

- Max. tensile load, kN:

- 90

- Max. operating load, kN:

- 60-72

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Connection thread of sucker rods, inch (mm):

- 3/4 (19), 7/8 (22), 1 (25)

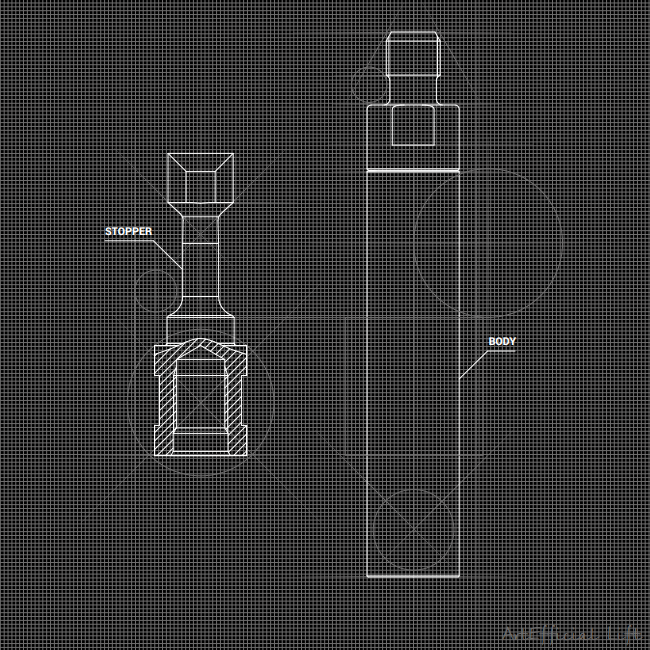

On/off tool

Application

On/off tool is designed to connect/disconnect sucker rod pump plunger to/from sucker rod string.

Advantages

- Safely disconnect clogged plunger from sucker rod string;

- Prevent penetration of solids and foreign matters into the sub-plunger space in process of pump running in well;

- Prevent plunger damaging by tubing string while running-in;

- Easy plunger fitting into barrel;

- Prevent spontaneous uncoupling;

Benefits

- Installation of oversized SRP in current tubing string;

- Time & technological cost reduction due to exclusion of combined pull-out;

- Higher reliability of sucker rod pumping system;

Order reference

ON/OFF TOOL-25-7/8″ SR

25 (2 7/8”) – tubing ID

7/8” SR – connection thread of sucker rods

Technical specification

- Max. operating load, kN (kgf):

- up to 105 (11000)

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Connection thread of sucker rods, inch (mm):

- 3/4 (19), 7/8 (22), 1 (25)

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia