Sand-gas anchor

Application

Anchor is used to neutralize or substantially reduce negative effects of solids and gas penetrating into operating parts of sucker rod pumps and surface equipment.

Advantages

- High separation coefficient – up to 95%;

- Adjustable sand trap length, 33-328 ft (10-100 m);

- Multi-purpose design for simultaneous

separation of solids and gas;

Benefits

- Prevents early wear of downhole equipment;

- Reduced risk of failure caused by pump clogging;

- Longer runlife of sucker rod pumping system;

- Well repair cost reduction;

- Higher efficiency of sucker rod pumping system;

Order reference

PG-20

20 (2 3/8″) – tubing ID

Technical specification

- Tubing ID , inch (mm):

- from 2 3/8 (60)

- Casing ID, inch (mm):

- from 4 (102)

- Anchor setting angle, degree:

- up to 55

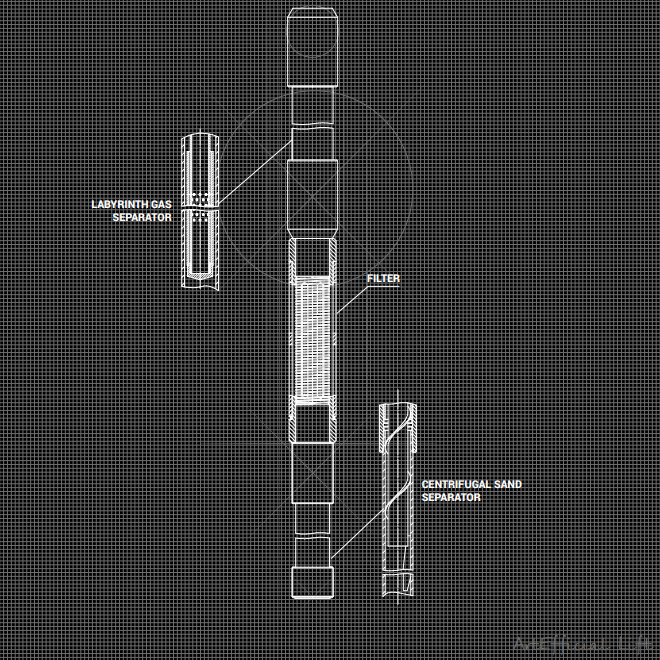

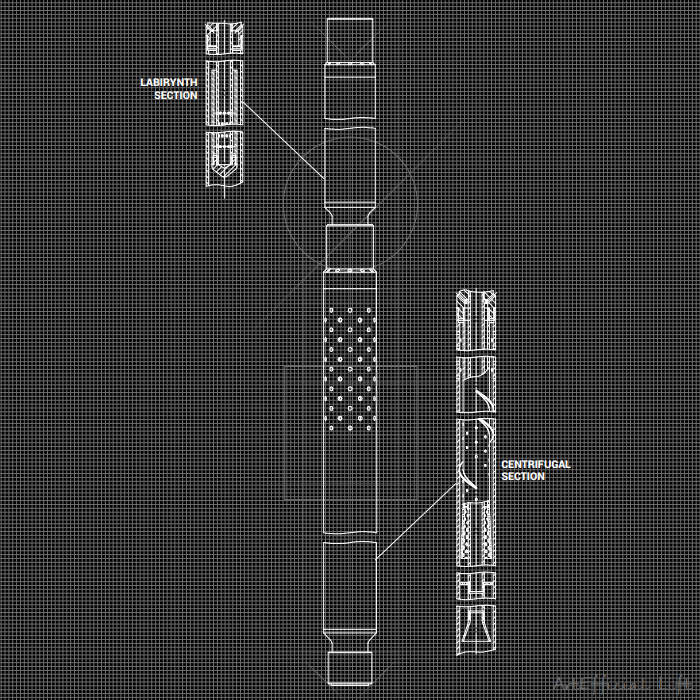

Gas separator

Application

Gas separator is designed to separate gas from formation fluid in process of sucker rod pump operation.

Advantages

- High separation coefficient – up to 98%;

- 3-stage separation;

- Separator can be used with small-ID casings;

- Separator is easy to install, operate and repair;

Benefits

- Higher efficiency of pump operation with

high concentration of free gas; - Reduced risk of pump failure caused by gas lock;

- Longer runlife of sucker rod pumping system;

- Reduced well repair cost;

- Partial sand separation;

Order reference

GS-25

25 (2 7/8″) – tubing ID

Technical specification

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Casing ID, inch (mm):

- from 4 (102)

- Modular type:

- product is equipped with centrifugal and/or labyrinth section

- Flow rate, bopd (m3 /d):

- up to 1885 (300)

- Gas-oil ratio (GOR), scf/stb (m3 /m3 ):

- up to 2805 (500)

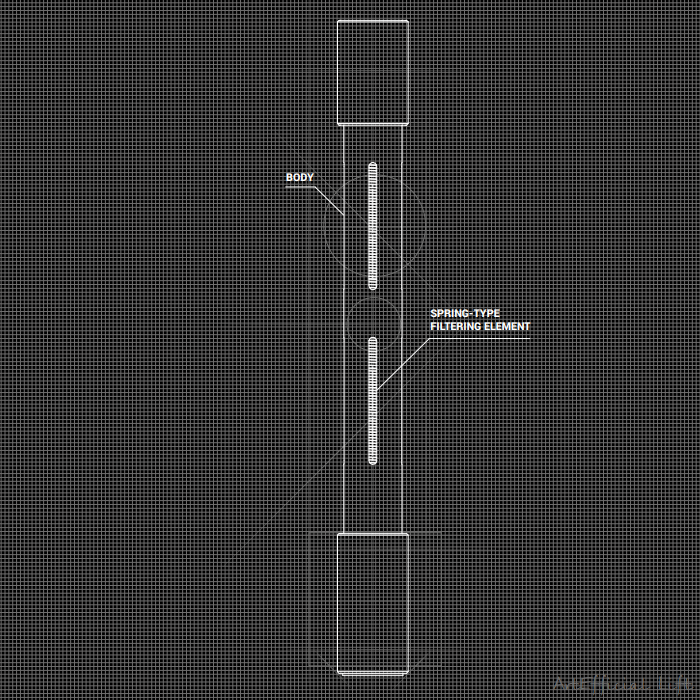

Sand screen filter adjustable

Application

Adjustable sand screen filter is designed to prevent solids penetration into operating parts of sucker rod pump.

Advantages

- Adjustable turn-to-turn clearance – 0.0039-0.039 inch (0.1-1 mm) – to adjust filtration capacity;

- Cascade connection of several sections is available;

- Self-cleaning spring-type filtering element;

Benefits

- Prevents early wear of downhole equipment;

- Reduced risk of downhole equipment

failure caused by clogging; - Longer runlife of sucker rod pumping system;

- Reduced repair cost of sucker rod pumping system;

Order reference

SSFA-SRP-30

30 (3 1/2″) – tubing ID

Technical specification

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Casing ID, inch (mm):

- from 4 (102)

- Flow rate, bopd (m3 /d):

- up to 6290 (1000)

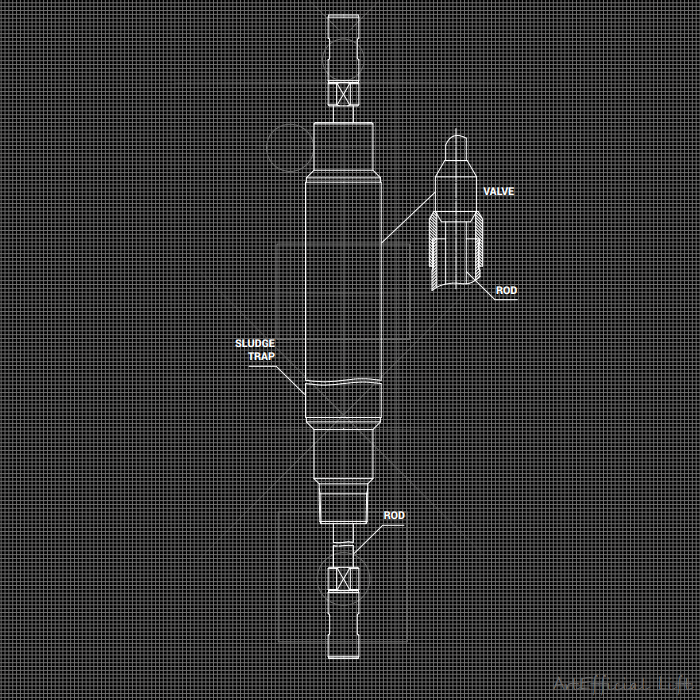

Sand prevention pipe

Application

Prevents solids penetration when SRP operation is suspended.

Advantages

- Sludge trap size can be increased;

- Prevents solids penetration into operating parts of the pump;

- Reliable pump start;

Benefits

- Reduced risk of sucker rod string break due to plunger clogging;

- Longer runlife of sucker rod pumping system due to slower wear of barrel-plunger;

Order reference

SPP-25-175-RHAM

325 (2 7/8″) – tubing ID

175 – pump size

Technical specification

- Tubing ID, inch (mm):

- from 2 3/8 (60)

- Casing ID, inch (mm):

- from 4 (102)

- Stroke length, inch (mm):

- up to 315 (8000)

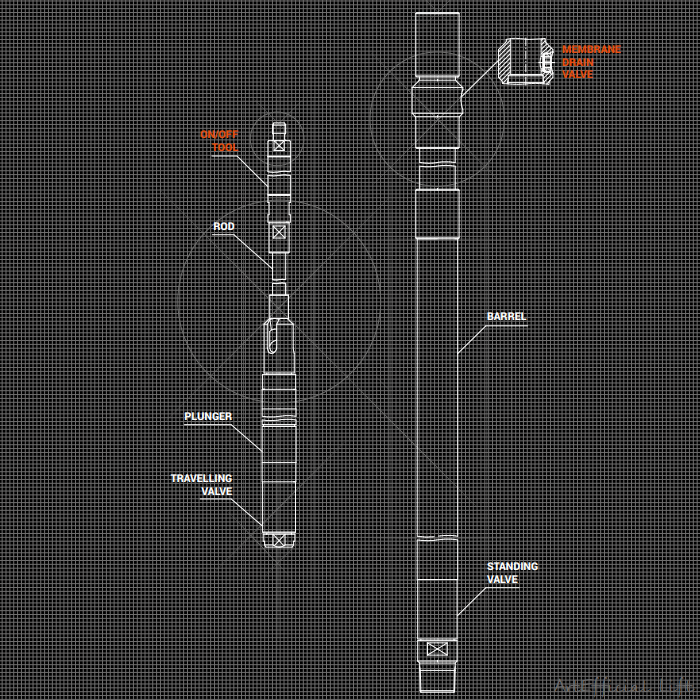

THOS pump with non-retrievable plunger

Application

Pump is designed for operation of wells with small-size casing from 4 inches (102 mm) with wall thickness up to 0.33 inch (8.6 mm).

Advantages

- Plunger OD is larger than tubing ID;

- Design prevents damage and clogging

in process of run-in-the-hole; - Pump is equipped with on/off tool and drain valve;

Benefits

- Increased flow rate with tubing string of same diameter;

- Reduced drilling cost;

Order reference

20-225-THOS-18-4-0-0-ST-fit2

Technical specification

- Pump type:

- tubing

- Nominal size:

- 57 (225), 63 (250), 70 (275), 83 (325), 95 (375)

- Tubing diameter, inch (mm):

- from 2 3/8 (60)

- Casing diameter, inch (mm):

- from 4 (102)

- Stroke, inch (mm):

- up to 235 (6000)

- Pump head, ft (m):

- up to 5905 (1800)

- Estimated flow rate, bopd (m3 /d):

- up to 1885 (300)

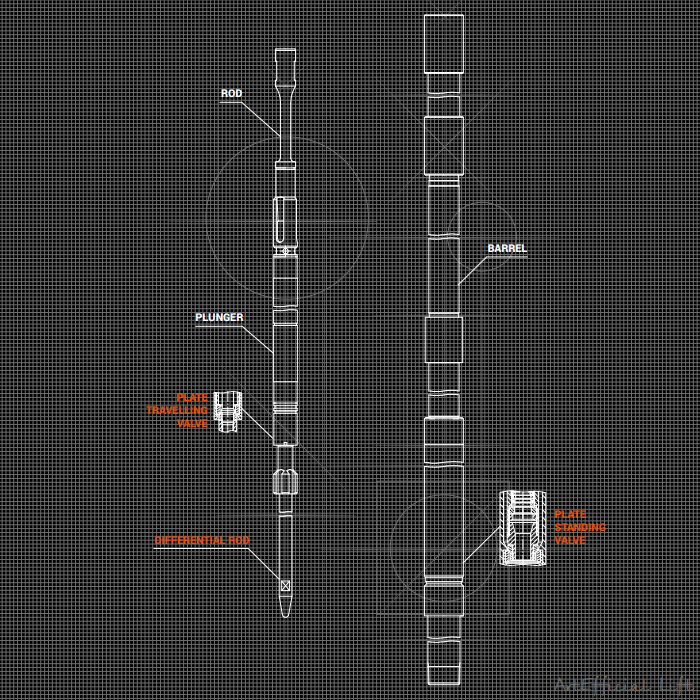

SPeaR pump with plate valves

Application

Pump is designed for operation in wells with boreholes of complex geometry, deep, deviated and horizontal wells (up to 90°), sidetracks, slim holes, and wells with highly viscous emulsions.

Advantages

- Continuous sucker rod string tension due to differential rod application;

- Plate standing and travelling valves;

Pump pull-out without additional drain device; - Guided plate valves provide strict axial stroke which prevents valves floating;

- Positive closing of standing and travelling valves;

- High-temperature modification up to 572°F (300°C);

Benefits

- Prevents sucker rods floating;

- Increased efficiency ratio;

- Efficient performance in deviated wells;

- Alternative option to small-size ESP.;

Order reference

SPeaR (P) 44/24

44 –nominal pump size

24 – differential rod OD

Technical specification

- Pump type:

- tubing, special

- Nominal size:

- 44 (175), 57 (225), 70 (275)

- Tubing diameter, inch (mm):

- from 2 3/8 (60)

- Stroke, inch (mm):

- up to 315 (8000)

- Pump head, ft (m):

- up to 7215 (2200)

- Estimated flow rate, bopd (m 3 /d):

- up to 565 (90)

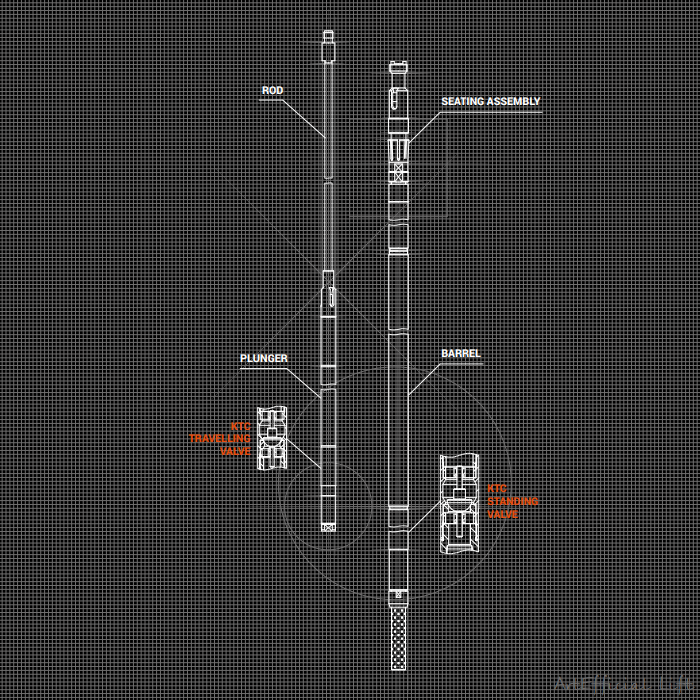

Sucker rod pump with KTC hemisphere valves

Application

Operation of directional wells (up to 70°) complicated by high viscosity oil.

Advantages

- Elimination of problem of valve floating due

to axial movement of hemispheres; - Increased flow cross sections in KTC valve body;

- No damage to valve body by hemisphere during oil production;

Benefits

- Efficient operation in directional wells;

- Increased SRP efficiency;

- Low SRP failure-related cost;

- Low sucker rod floating probability;

Order reference

25-175-RHBM-КТС-14-4-2-2-ТС-fit2

Technical specification

- Pump type:

- insert, tubing

- Nominal size:

- 27 (106), 32 (125), 38 (150), 44 (175), 50 (200), 57 (225), 63 (250), 70 (275), 95 (375)

- Tubing OD, inch (mm):

- from 2 3/8 (60)

- Stroke, inch (mm):

- up to 315 (8000)

- Head, ft (m):

- up to 9850 (3000)

- Ideal flow rate, bopd (m3 /day):

- up to 1885 (300)

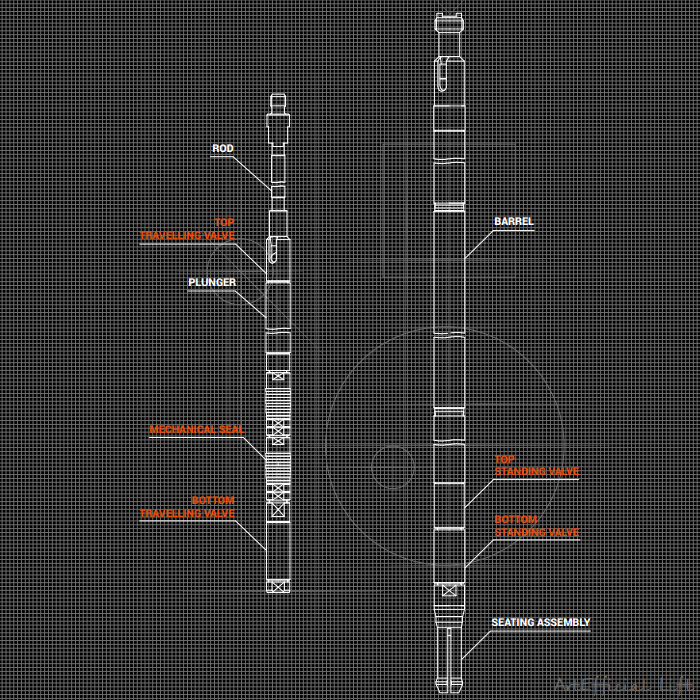

Deep-diver pump

Application

Pump is designed for oil production in wells up to 9850 ft (3000 m) deep

Advantages

- Pump head characteristics are improved by additional mechanical seals on plunger;

- Doubled standing and travelling valves;

- Reinforced rod;

Benfits

- Pump efficiency is maintained at depth up to 9850 ft (3000 m);

- Pump is an alternative option to small-size ESP;

- Well continues SRP oil production in

case of dynamic level drops;

Order reference

25-175-DDP-16-4-3-2-ST-fit1

Technical specification

- Pump type:

- tubing, insert

- Nominal size:

- 27 (106), 32 (125), 38 (150), 44 (175), 57 (225)

- Tubing diameter, inch (mm):

- from 2 3/8 (60)

- Stroke, inch (mm):

- up to 235 (6000)

- Pump head, ft (m):

- up to 9850 (3000)

- Estimated flow rate, bopd (m3 /d):

- up to 818 (130)

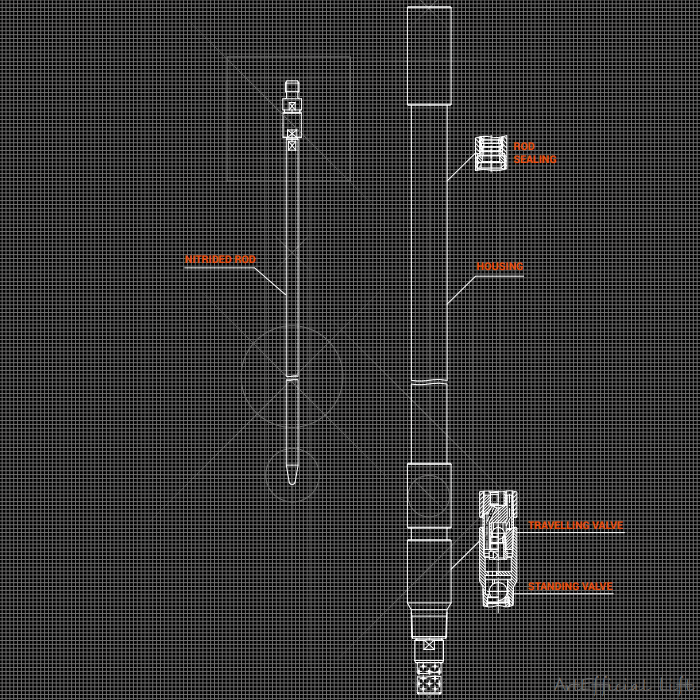

Sipper pump

Application

Pump is designed for operation in low-rate wells from 3.1 bopd (0.5 m3

/d).

Advantages

- Simple design;

- Enlarged seat & ball valves and larger flow section;

- Housing with mechanical rod seals (no conventional barrel required);

- Nitrided rod functions as plunger;

Benefits

- Reduced load on sucker rod string increases setting depth;

- Non-stop operation of low rate wells even at minimum flow;

- Reduced risk of pump clogging;

- Production of highly viscous oil and emulsions;

Order reference

SIPPER-24

24 – rod OD

Technical specification

- Pump type:

- tubing

- Nominal size:

- 24, 32 (125)

- Tubing diameter, inch (mm):

- from 2 3/8 (60)

- Stroke, inch (mm):

- up to 135 (3500)

- Pump head, ft (m):

- up to 6560 (2000)

- Estimated flow rate, bopd (m3 /d):

- 3.1-150 (0.5-24)

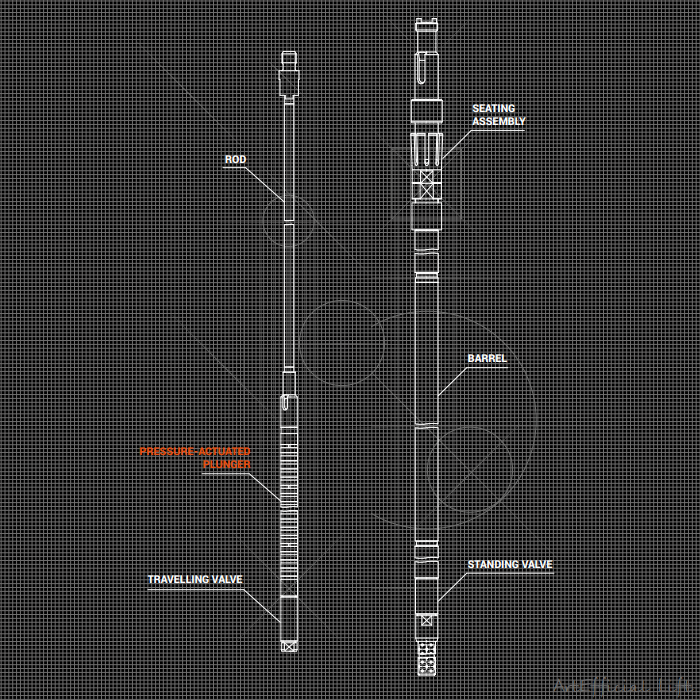

RHAMZes Pump

Application

Pump is designed for operation in boreholes with high concentration of solids (up to 8 g/l).

Advantages

- Increased clearance in barrel-plunger pair prevents

from clogging in case of solids penetration; - Polymeric rings ensure steady flow;

- Pressure-actuated plunger can be installed in

pumps of any modification and size;

Benefits

- Prevents pump from clogging;

- Reduced wear of barrel-plunger pair;

- Decreased repair cost for sucker rod pump;

- Higher well runlife;

Order reference

25-150-RHAM-Z-20-5-1-1-ST

Technical specification

- Pump type:

- insert, tubing

- Nominal size:

- 32 (125), 38 (150), 44 (175), 57 (225), 70 (275), 83 (325), 95 (375)

- Tubing diameter, inch (mm):

- from 2 3/8 (60)

- Stroke, inch (mm):

- up to 235 (6000)

- Pump head, ft (m):

- up to 4920 (1500)

- Estimated flow rate, bopd (m3 /d):

- up to 1350 (215)

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia