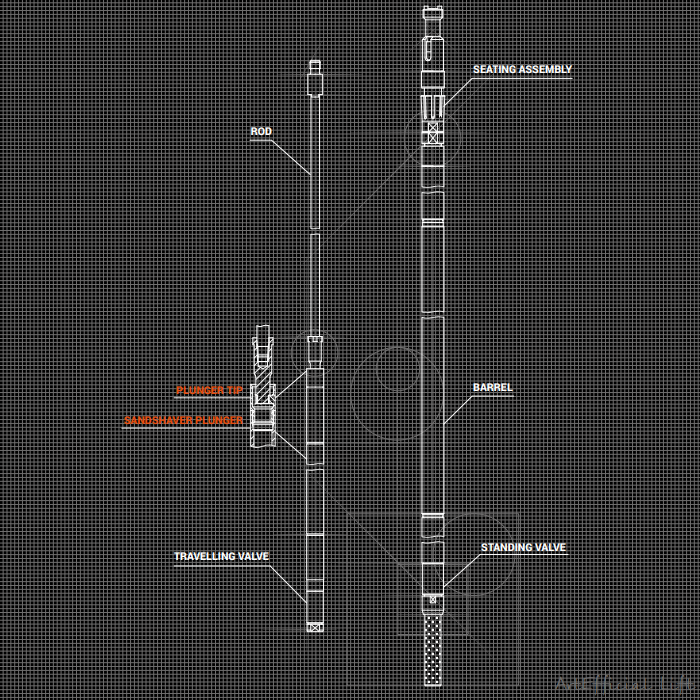

Sandshaver pump

Application

Pump is designed for operation in boreholes with high solids content (up to 8 g/l).

Advantages

- Plunger with sharp edge cone top removes solids and salt deposits from barrel walls flushing

away with fluid flow delivered by pump; - Prevents solids accumulation in barrel-plunger clearance;

- Sandshaver plunger can be installed in

pumps of any modification and size;

Benefits

- Prevents pump clogging;

- Reduced wear of barrel-plunger pair;

- Higher well runlife;

Order reference

25-175-TНМ(SSP)-11-3-2-3-TC-fit2

Technical specification

- Pump type:

- Insert, tubing

- Nominal size:

- 27 (106), 32 (125), 38 (150), 44 (175), 50 (200), 57 (225), 63 (250), 70 (275), 95 (375)

- Tubing diameter, inch (mm):

- from 2 3/8 (60)

- Stroke, inch (mm):

- up to 315 (8000)

- Pump head, ft (m):

- up to 9850 (3000)

- Estimated flow rate, bopd (m3 /d):

- up to 1885 (300)

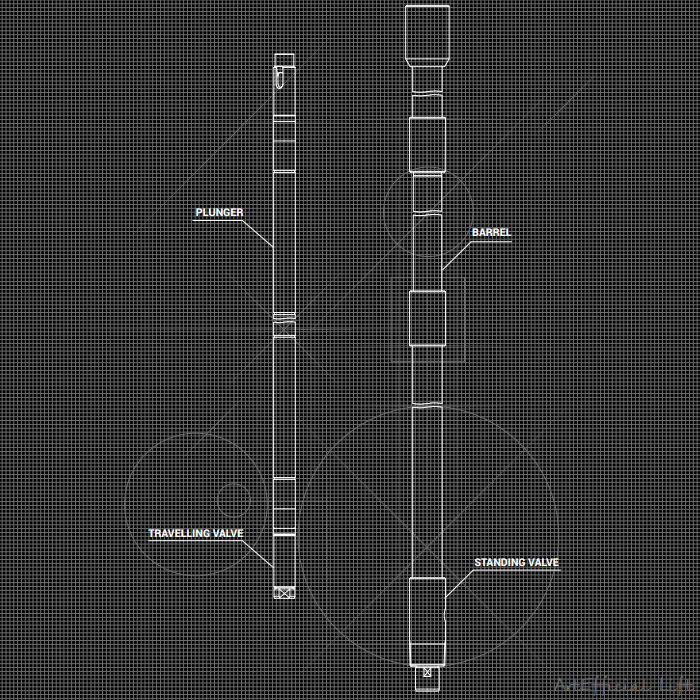

Short-barrel pump

Application

Pump is designed for operation in boreholes with high solids content (up to 2.5 g/l).

Advantages

- Reduced wear of barrel-plunger pair;

- Prevents pump from clogging as solids are washed off;

- Conventional pump components provide easier repairbility;

Benefits

- Reduced risk of pump clogging;

- Fewer well treatment operations;

- Reduced costs on well repair due to higher pump runlife;

Order reference

25-125-ТНМ-4-10-2-12-SS-fit4

Technical specification

- Pump type:

- Insert, tubing

- Nominal size:

- 27 (106), 32 (125), 38 (150), 44 (175), 50 (200), 57 (225), 63 (250), 70 (275)

- Tubing diameter, inch (mm):

- from 2 3/8 (60)

- Stroke, inch (mm):

- up to 175 (4500)

- Pump head, ft (m):

- up to 9850 (3000)

- Estimated flow rate, bopd (m3 /d):

- up to 785 (125)

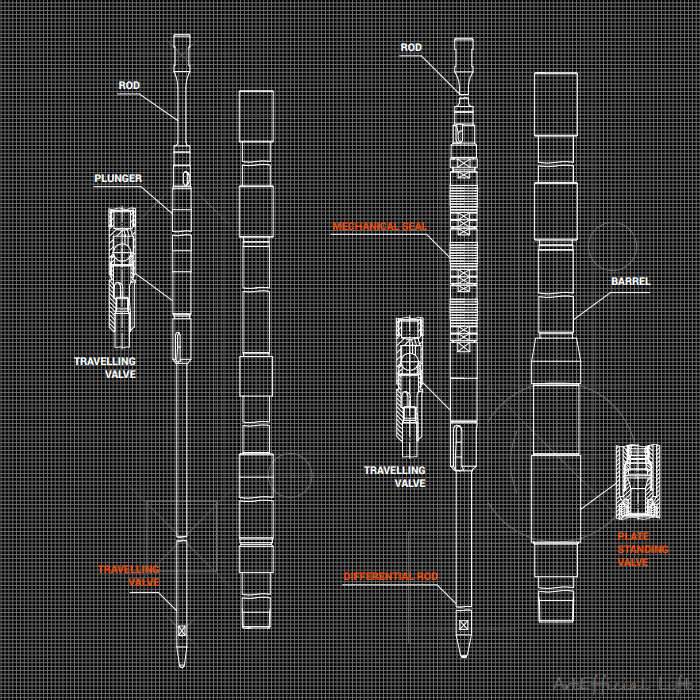

SPeaR Pump

Application

Production of highly viscous oil & emulsions (up to 250 mPa·s) without reduction of flow rate

Advantages

- Continuous sucker rod string tension due

to differential rod application; - Pump pull-out without additional drain device;

- High-temperature modification up to 572°F (300°C);

- High-sand production modification (up to 2.5 g/l);

- Positive closing of standing valve;

Benefits

- Sucker rod string floatation is prevented;

- Higher pump efficiency;

Order reference

SPeaR 44*/24

24 – differential rod OD

Technical specification

- Pump type:

- specialized tubing

- Nominal size*:

- 44 (175), 57 (225), 70 (275)

- Tubing diameter, inch (mm):

- from 2 3/8 (60)

- Stroke, inch (mm):

- up to 315 (8000)

- Pump head, ft (m):

- up to 7215 (2200)

- Estimated flow rate, bopd (m3 /d):

- up to 880 (140)

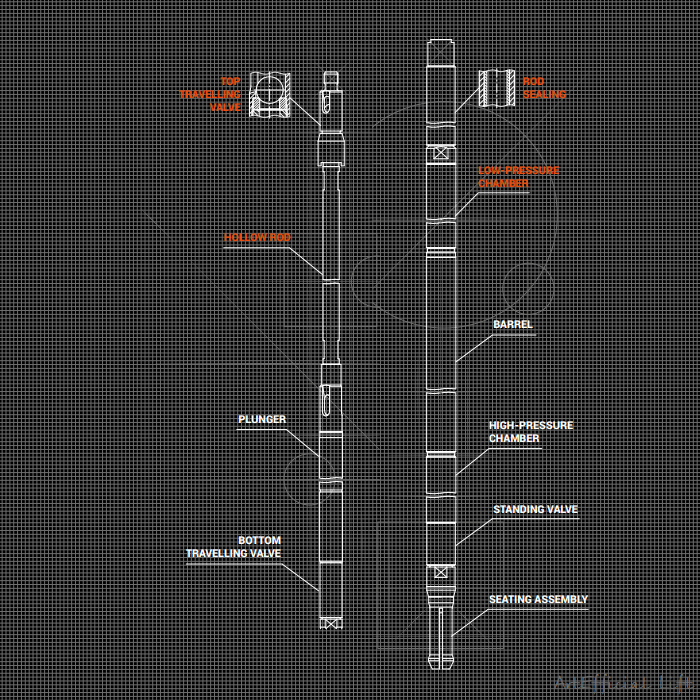

Differential gas pump

Application

Production of fluid with high GOR: up to

60% of free gas on pump intake.

Advantages

- Top travelling valve creates low-pressure chamber under

bottom standing valve by shutting off hydrostatic fluid column; - User-friendly design and installation;

- Steady performance at high GOR;

Benefits

- Well treatment reduction;

- Prevention of downhole equipment premature failure;

- Prevention of gas lock;

- Higher pump efficiency in comparison with conventional SRP;

Order reference

25-150/125-RHBM-G-14-4-2-2-TC-fit2

150 – nominal pump size

125 – hollow rod ID

Technical specification

- Pump type:

- insert pump

- Nominal size:

- 38 (150), 44 (175), 57 (225)

- Tubing diameter, inch (mm):

- From 2 3/8 (60)

- Stroke, inch (mm):

- up to 135 (3500)

- Pump head, ft (m):

- up to 6890 (2100)

- Estimated flow rate, bopd (m3 /d):

- up to 440 (70)

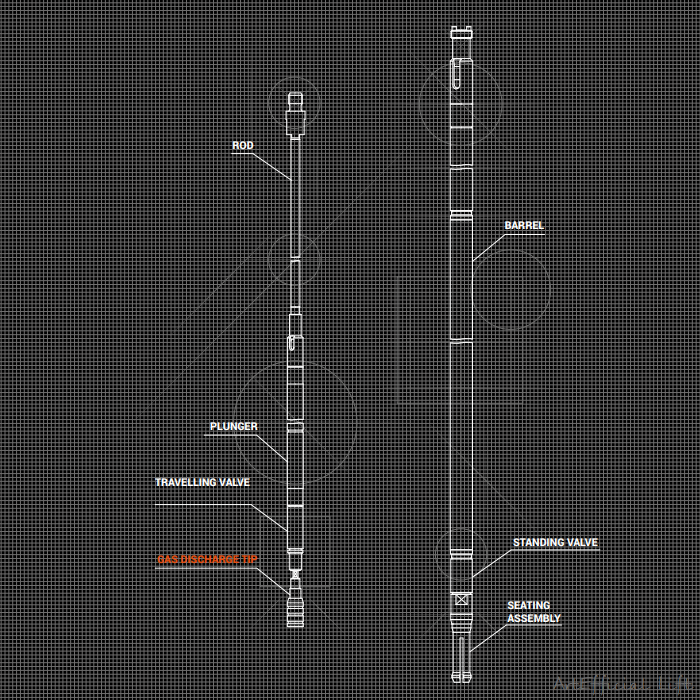

Sucker rod pump with gas discharge tip

Application

Production of fluid with high GOR: up to

30% of free gas on pump intake.

Advantages

- Positive opening of travelling valve;

- Suitable for any SRP;

Benefits

- Well treatment reduction;

- Prevention of downhole equipment premature failure;

- Prevention of gas lock;

- Higher pump efficiency in comparison to conventional SRP;

Order reference

25-175-RHBM(GDT)-16-5-2-1-SS-fit1

Technical specification

- Pump type:

- Insert, tubing

- Nominal size:

- 27 (106), 32 (125), 38 (150), 44 (175), 50 (200), 57 (225), 63 (250), 70 (275), 95 (375)

- Tubing diameter, inch (mm):

- from 1.9 (48)

- Stroke, inch (mm):

- up to 315 (8000)

- Pump head, ft (m):

- up to 9850 (3000)

- Estimated flow rate, bopd (m3 /d):

- up to 1885 (300)

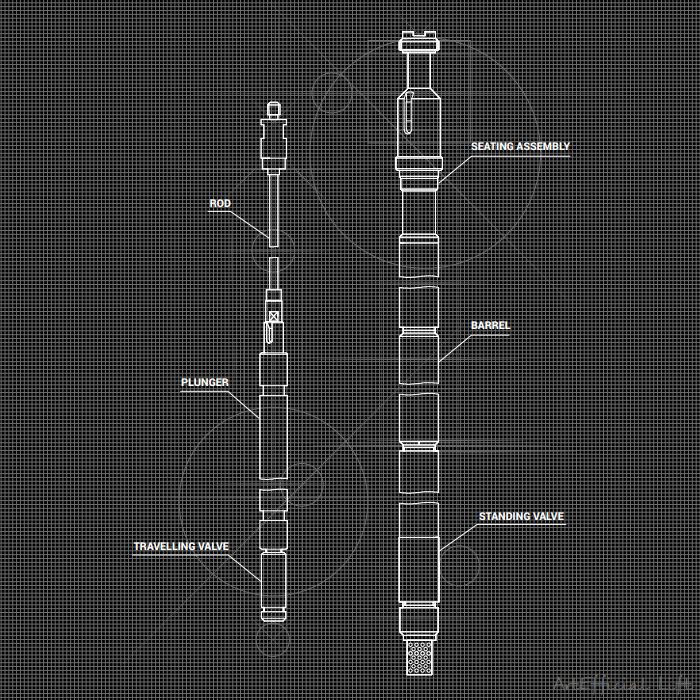

Insert sucker rod pump

Advantages

- Workover cost is reduced as pump can be

replaced without tubing pullout; - All types of seating assemblies are available;

- Various options of barrels, plungers and seat & ball

valves for different operating conditions are available; - Pump can be equipped with high-strength

rod to increase pump reliability;

Technical specification

- Nominal size:

- 27 (106), 32 (125), 38 (150), 44 (175), 50 (200), 57 (225), 63 (250) other sizes are available on Customer’s request

- Flow rate, bopd (m3 /d):

- up to 850 (135)

- Pump head, ft (m):

- up to 9850 (3000)

- Stroke, inch (mm):

- Up to 235 (6000)

- Design options:

- API 11AX, Customer’s specifications

- Barrel type:

- thin wall, heavy wall

- Position of seating assembly:

- top, bottom

- Seating assembly type:

- mechanical, friction, cup

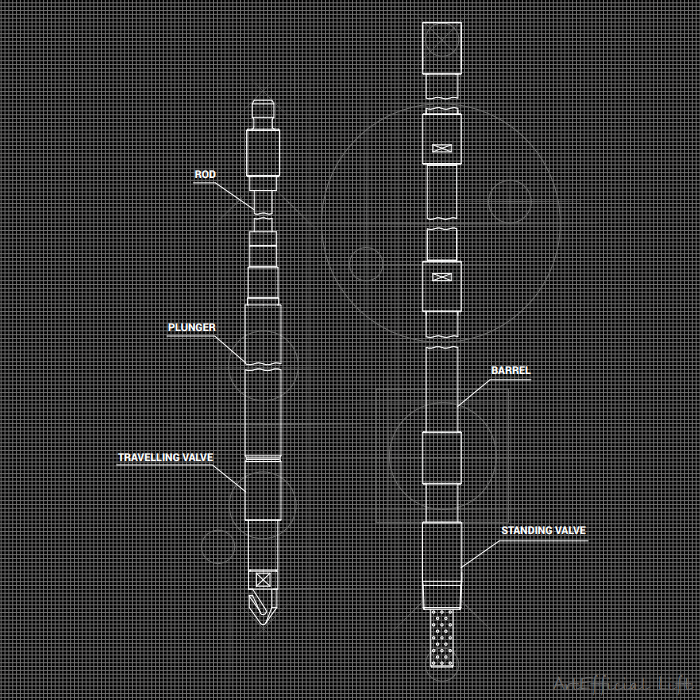

Tubing sucker rod pump

Advantages

- In comparison to insert pump, barrel of tubing pump

can be same or bigger than tubing string; - Various options of drain valves are available: breakable

plug, retrievable standing valve, calibrated burst plate; - Various design options of barrels, plungers and seat & ball

valves for different operating conditions are available; - Pump can be equipped with high-strength

rod to increase pump reliability;

Technical specification

- Nominal size:

- 32 (125), 38 (150), 44 (175), 57 (225), 70 (275), 95 (375) other sizes are available on Customer’s request

- Flow rate, bopd (m3 /d):

- up to 1885 (300)

- Pump head, ft (m):

- up to 9850 (3000)

- Stroke, inch (mm):

- up to 315 (8000)

- Design options:

- API 11AX, Customer’s specifications

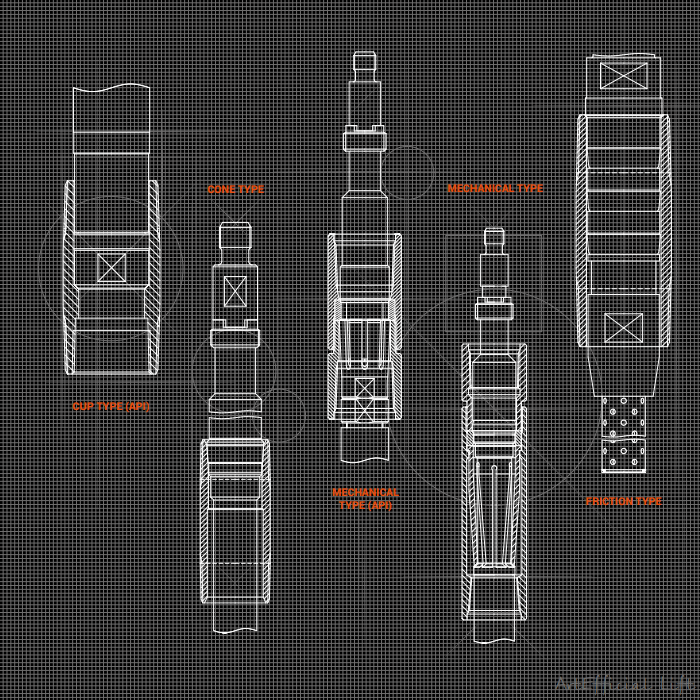

Seating assembly

Application

Seating assemblies are used to lock insert sucker rod pumps in tubing string and to keep fluid above pump.

Advantages

Sucker rod pump can be equipped with seating assembly of any type and size

according to operating conditions and Customer’s specifications.

| Type | ELKAM code | Tubing size, inch (mm) | Operating pressure, MPa (Psi) | Min. seating assembly separation force, kN |

|---|---|---|---|---|

| Mechanical Type | ОМ-60 | 2 3/8 (60) | 35 (5075) | 3,0 |

| ОМ-73 | 2 7/8 (73) | 30 (4350) | 3,5 | |

| ОМ-89 | 3 1/2 (89) | 25 (3625) | 3,5 | |

| Cone type | ОА-73-32 | 2 7/8 (73) | 30 (4350) | 3,5 |

| ОА-73 | 2 7/8 (73) | 30 (4350) | 3,5 | |

| ОА-89 | 3 1/2 (89) | 25 (3625) | 3,5 | |

| Mechanical Type (API) | НМ-60 | 2 3/8 (60) | 35 (5075) | 3,0 |

| НМ-73 | 2 7/8 (73) | 30 (4350) | 3,5 | |

| НМ-89 | 3 1/2 (89) | 25 (3625) | 3,5 | |

| Cup Type (API) | 1-32521 | 2 3/8 (60) | 35 (5075) | 3,0 |

| 1-32522 | 2 7/8 (73) | 30 (4350) | 3,5 | |

| 1-32523 | 3 1/2 (89) | 25 (3625) | 3,5 | |

| Friction Type | 1-32756-F | 2 3/8 (60) | 35 (5075) | 4,4…28,9 |

| 1-32757-F | 2 7/8 (73) | 30 (4350) | 4,4…28,9 | |

| 1-32758-F | 3 1/2 (89) | 25 (3625) | 4,4…28,9 |

ELKAM is a diploma winner of the contest “Gold Mercury”

For the past 3 years, ELKAM has been awarded the “Best Exporter of the Year” in the field of industrial production

2020 was very difficult, but thanks to well-coordinated teamwork and competent management strategy, we worthily met all the challenges and successfully completed the tasks we faced

ELKAM was recognized as a diploma winner in this category and was awarded with the gratitude of the Perm Chamber of Commerce and Industry

As you know, difficulties unite people. In finding solutions and overcoming obstacles, we have united, and this has allowed us not only to maintain a leading position, but also to open new horizons for development

We thank our partners and colleagues for trust and cooperation, this is our common award!

Providing our Customers with high-quality products on time

The epidemiological situation is stabilizing, and most of the restrictive measures have been lifted

The pandemic has had a negative impact on the operation of many enterprises in the industrial sector

But ELKAM company continues to work in normal mode – the production capacity is 100% loaded, thanks to a competent anti-crisis strategy, the volume of orders is not just saved, but also increased

Our main task is still to provide our Customers with high-quality products on time

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia