Submersible equipment

Each oil production company faces a problem of choosing a reliable and experienced contractor for repair of submersible equipment. ELKAM has its own workshop for repair the following downhole oil production equipment (conventional and specialized): sucker rods (solid, hollow, flexible cable); tubing; downhole pumps (SRPs, PCPs, ESPs); packers; equipment sets for simultaneous oil production and injection, etc. A list of repair works performed by our specialist includes cleaning of equipment from contamination, non-destructive testing (inspection), identification of defects, replacement of worn-out parts, equipment assembly and testing.

Control boxes

ELKAM has electrical laboratory where repair and modernization of control boxes are performed: replacement of defected modules and installation of new modules; testing; technological cutting of body; manufacturing and installation of supports (brackets) and other fixing components for the following installation of control box modules; body painting, printing and marking.

Well deparaffination unit

Well deparaffination unit (WDU) is used for dewaxing of tubing string of natural flow, gas-lift and ESP wells. ELKAM’s service department performs WDUs repair and commissioning including inspection / replacement of rollers, laying device, gear box, lubricator and motor. All the works are performed by trained and qualified personnel.

Installation supervision

Our specialists supervise equipment installation and well commissioning till operation start and pressure testing including equipment incoming inspection at Customer’s wellsite. Further they work in touch with oil production departments of our clients monitoring equipment operation efficiency. We also provide training programmes for Customer’a employees: servicing, installation, inspection, etc.

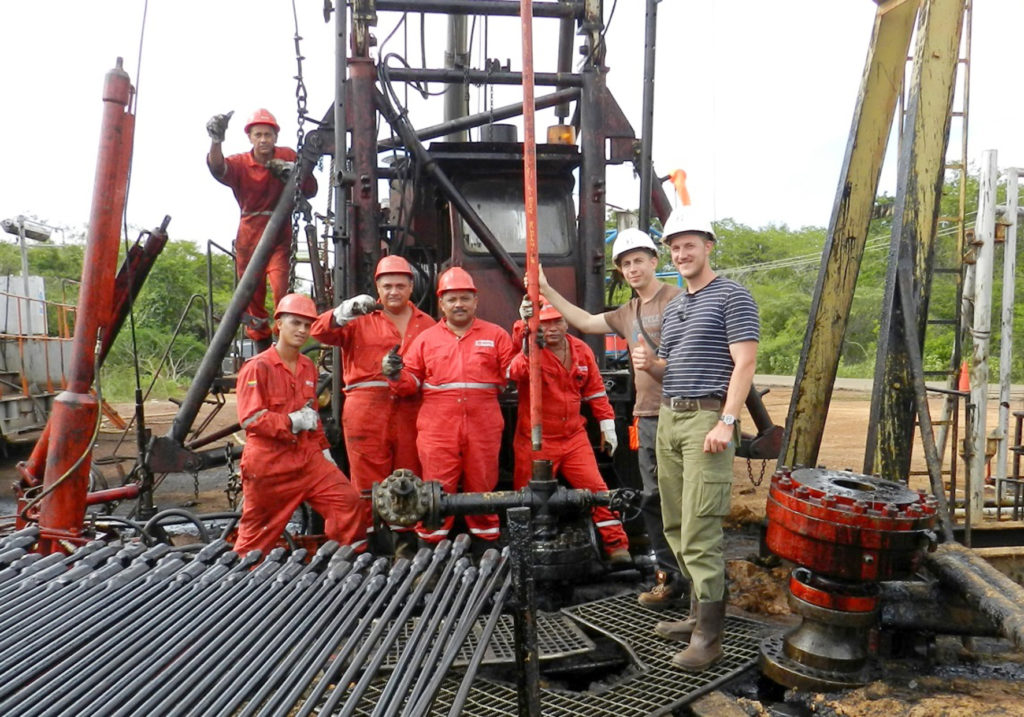

Commissioning

Commissioning – key technological process directly affecting on operation of downhole oil production equipment, its runlife and TBO as well as cost of produced oil. Commissioning works are performed by qualified specialists of our company with the application of necessary technological tools and in accordance with tested work performance procedures. We have ten year of successful commissioning performance at Customers’ complicated well fund increasing efficiency of equipment operation.

Supervising

Supervising means providing personnel services of control for all types of work at the wells, developing and delivering report documents to the Customer, coordinating activities of all the contractors involved in the operation process at the wellsite. We provide services of coordination and control for performance of drilling works, well survey, testing as per confirmed working plan and established safety rules and regulations. Presently ELKAM performs 5 supervision contracts.

Production method selection

Well operation is a technological process of well fluid lifting from formation to wellhead. Wells can be operated by different methods – free flow or artificial lift. Production method selection is performed on the basis of the following well data provided by a Customer: operation conditions, physical and chemical characteristics of well fluid, depth of productive formation, wellbore design. Specialists of ELKAM’s technological department select equipment for wells operated by both methods free flow and artificial lift: sucker rod pump, electric submersible pump, progressive cavity pump, jet pump, free flow.

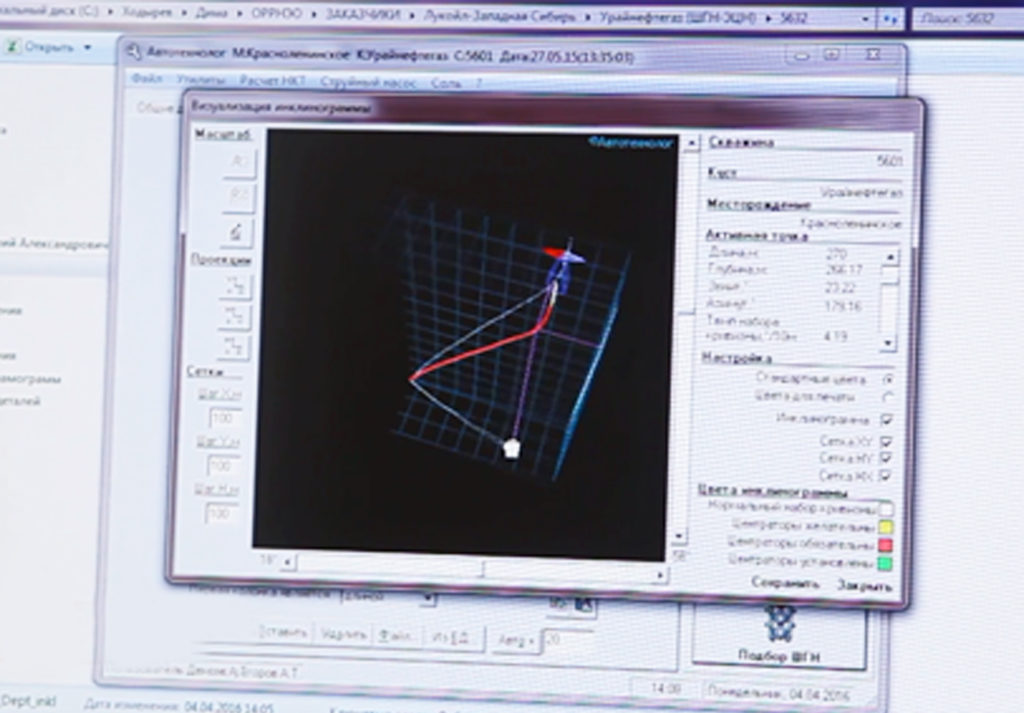

Well design

Well design of sufrace and subsurface pumping equipment depends on oil production conditions – gas-oil-ratio, viscosity and emulsions, well depth, quantity of solids, production rate, well profile, etc. ELKAM specialists make well design using “Autotehnologist” developed by Russian State University of Oil and Gas. On the basis of well data provided by a Customer we make the most appropriate well design with surface drive (beam pump, hydraulic pumping unit, belt drive), sucker rod pump, sucker rods string, tubing, pump accessories if necessary.

Formation pressure maintenance

ELKAM provides surface & subsurface equipment for formation pressure maintenance: water injection filtering element (W.I.F.E.) and ESP based injection pumping system. Our specialists can select and offer both separate elements or whole equipment sets as well as make an analysis of injected fluid characteristics, its volume and operating pressures. On the basis of Customer’s requirements we develop equipment set and well design, configuration and installation lay-out at wellhead.

Well operation mode

Well operation mode is a set of general paramerets of well operation which ensures safe and reliable well operation. Well operation mode is defined by the following main parameters: formation, bottom-hole and wellhead pressures; liquid flow rate; water cut, gas factor and quantity of solids; size & type of installed equipment, its operation data. Specialists of our company choose efficient operation mode of wells on the basis of the data provided by Customers and perform full service for its enhancement.

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia