Operation mode enhancement

Operation mode enhancement is primarily aimed at production growth and increase of TBO as well as wells maintenance by performance of various geo-technical works such us: bottom-hole formation zone treatment; commingling; additional perforation and re-perforation; deposits prevention and removal of them; operation mode enhancement and changing of operation method; etc. ELKAM provides full package of works aimed at operation mode enhancement of pumping sets and their selection.

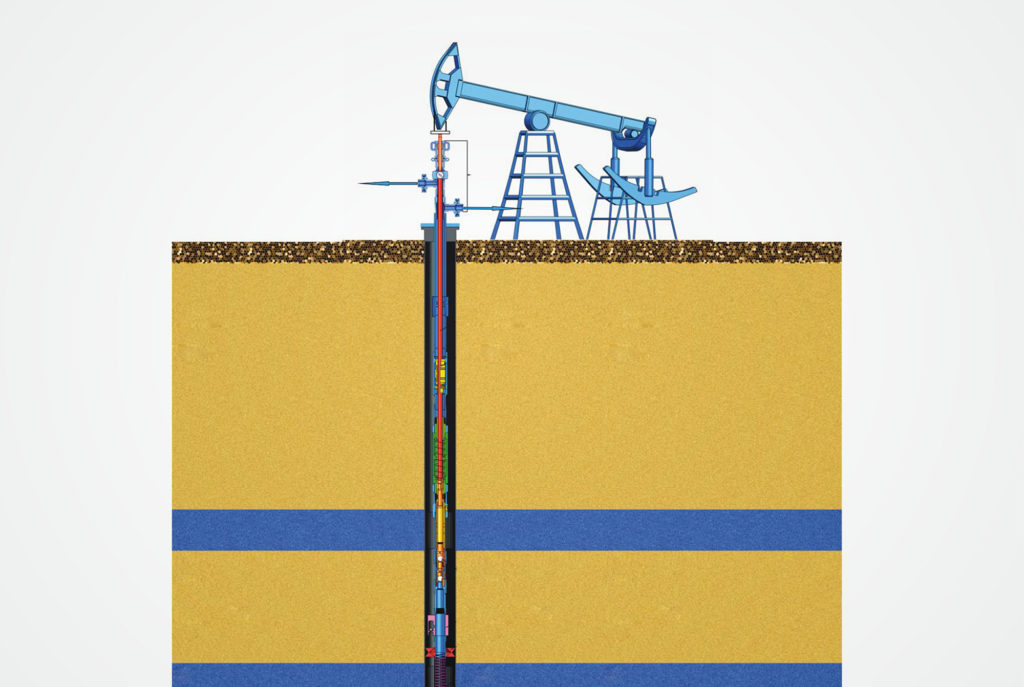

Multiformation production

Technology of multiformation oil production allows recovering of oil simultaneously from two formations of a single well with separate flow rate measuring of each formation; increasing oil production; involving idle formations and reducing drill footage. For dual formation oil production the following pump types can be used: SRP-SRP, ESP-SRP as well as ESP-ESP, natural flow-natural flow. Sucker rod pumps can be specially designed for complicated well conditions or equipped with accessories.

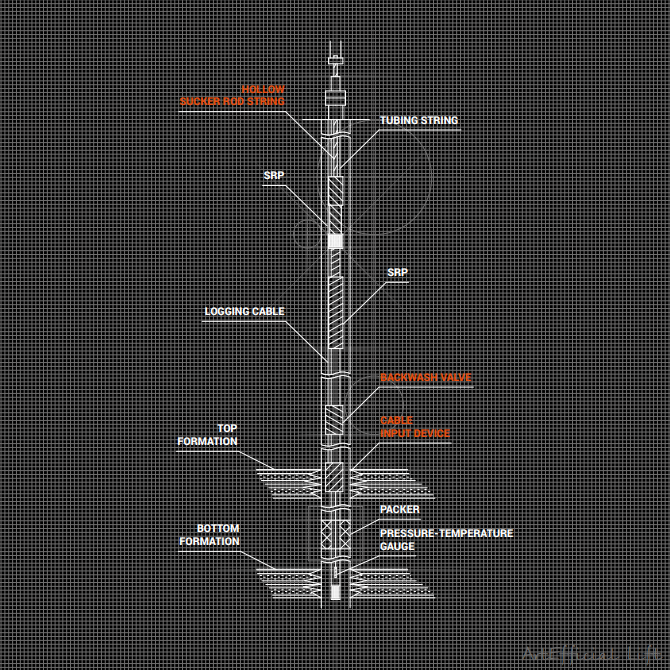

Dual completion SRP-SRP

Dual completion SRP-SRP is used for simultaneous dual oil production from two formations.

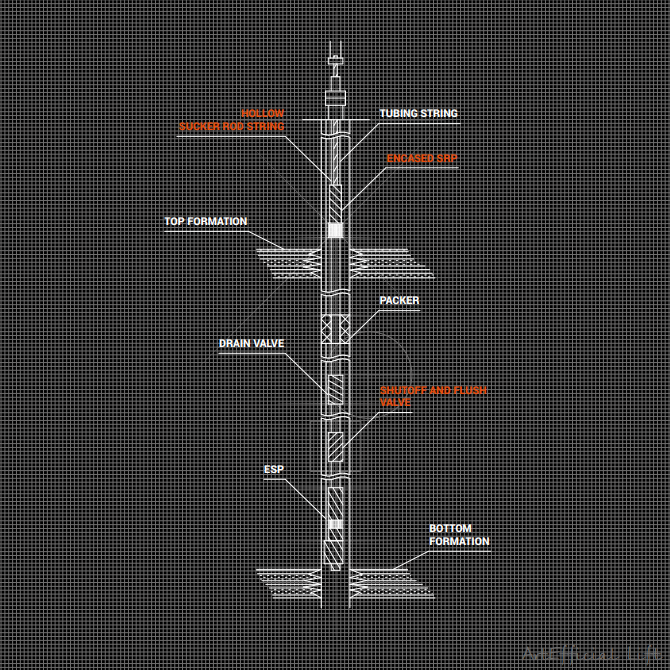

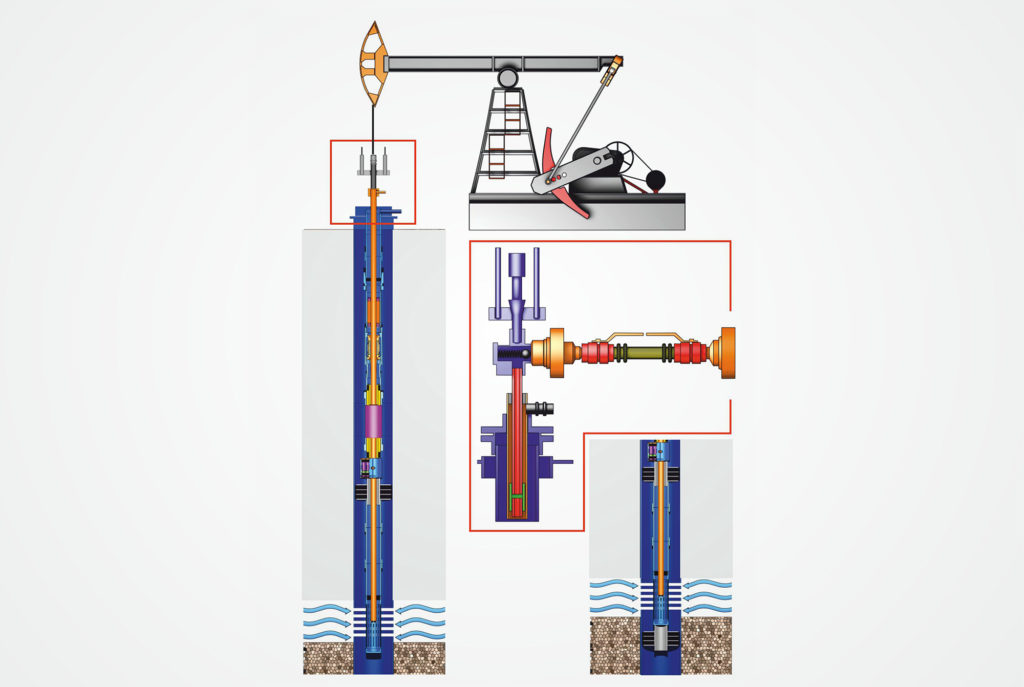

Dual completion ESP-SRP

Dual completion ESP-SRP equipment is used for simultaneous dual oil production from two formations according to scheme: bottom – ESP, top – SRP.

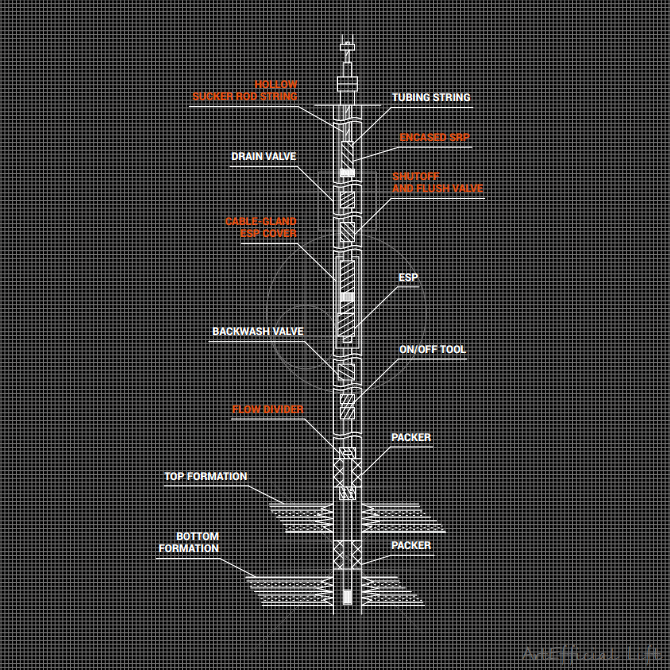

Dual completion SRP-ESP

Dual completion SRP-ESP equipment is used for simultaneous dual oil production from two formations according to scheme: bottom – SRP, top – ESP.

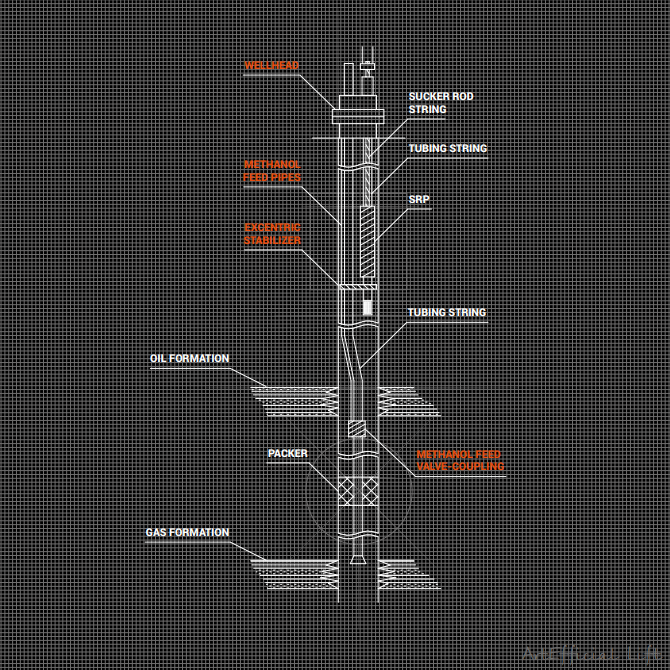

Dual completion GAS-SRP

Dual completion GAS-SRP equipment is used for simultaneous dual oil and gas production from two formations according to scheme: bottom – gas, top – SRP.

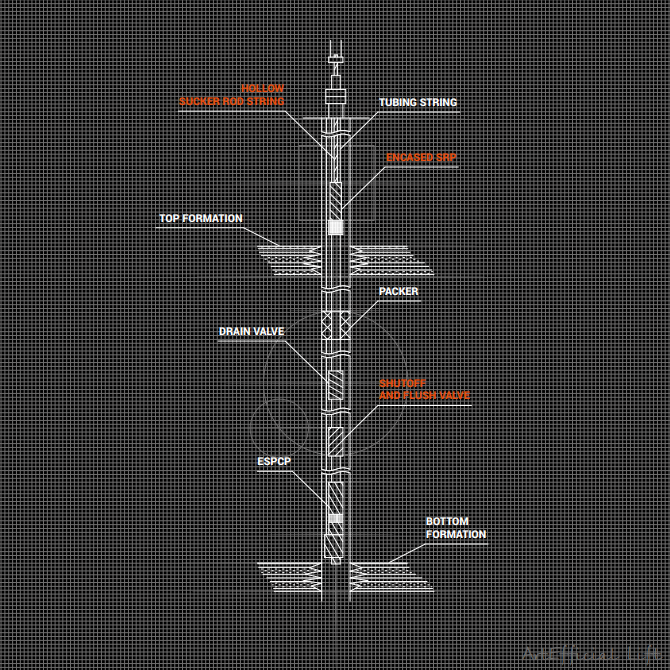

Dual completion ESPCP-SRP

Dual completion ESPCP-SRP equipment is used for simultaneous dual oil production from two formations according to scheme: bottom – ESPCP, top – SRP.

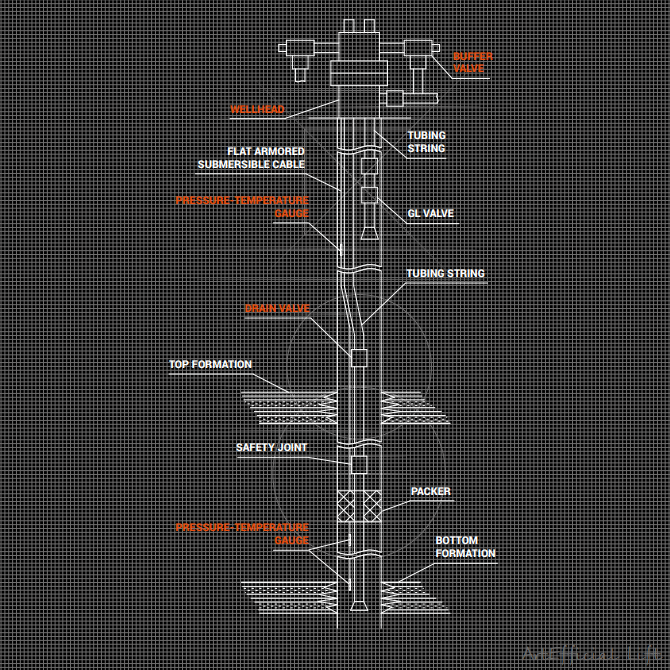

Dual completion natural flow-natural flow

Dual completion natural flow-natural flow is used for simultaneous dual oil production from two formations according to scheme: bottom – natural flow, top – natural flow.

Multiformation production & injection

Dual pumping and bottom-hole agent injection equipment is used upon exploitation of oilfields with such complications as high viscosity and ARWD when bottom-hole formation zone treatment is necessary. Equipment set includes specialized sucker rod pump with hollow rod for agent injection below the pump. Application of flush valve allows, if necessary, valves washing of differential pump and well killing. Overheated steam can be used as an agent for bottom-hole formation treatment (in this case all the equipment should be heat-resistant).

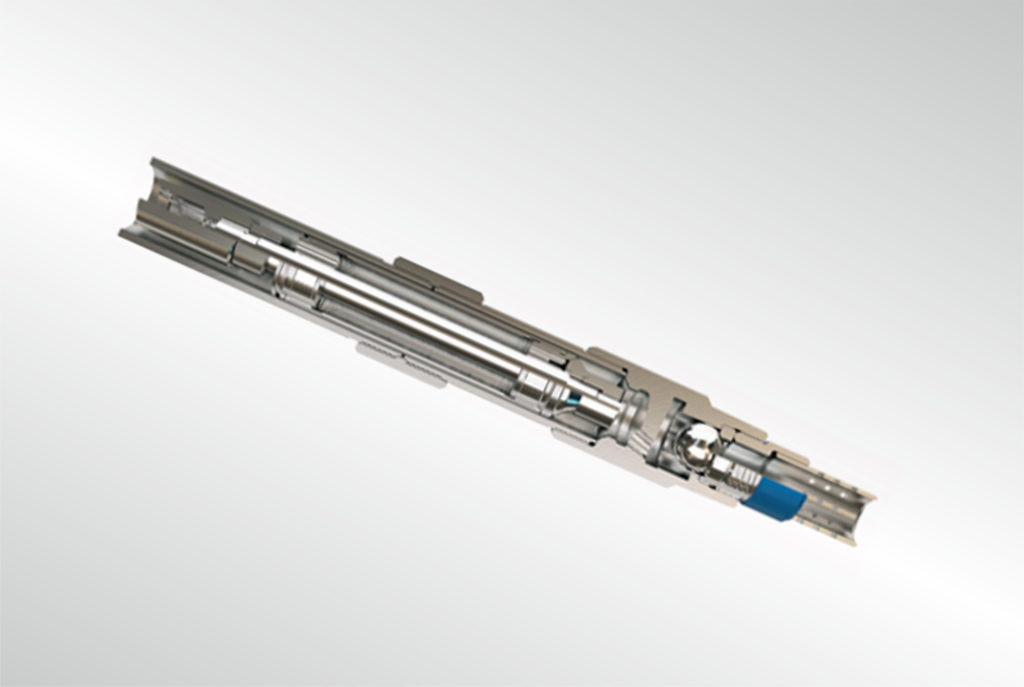

Sucker rod pumps

ELKAM performs full cycle of manufacturing of sucker rod pumps – from workpiece to pump assembling and hydraulic pressure testing.

Workpieces are purchased from certified and approved suppliers both Russian and foreign.

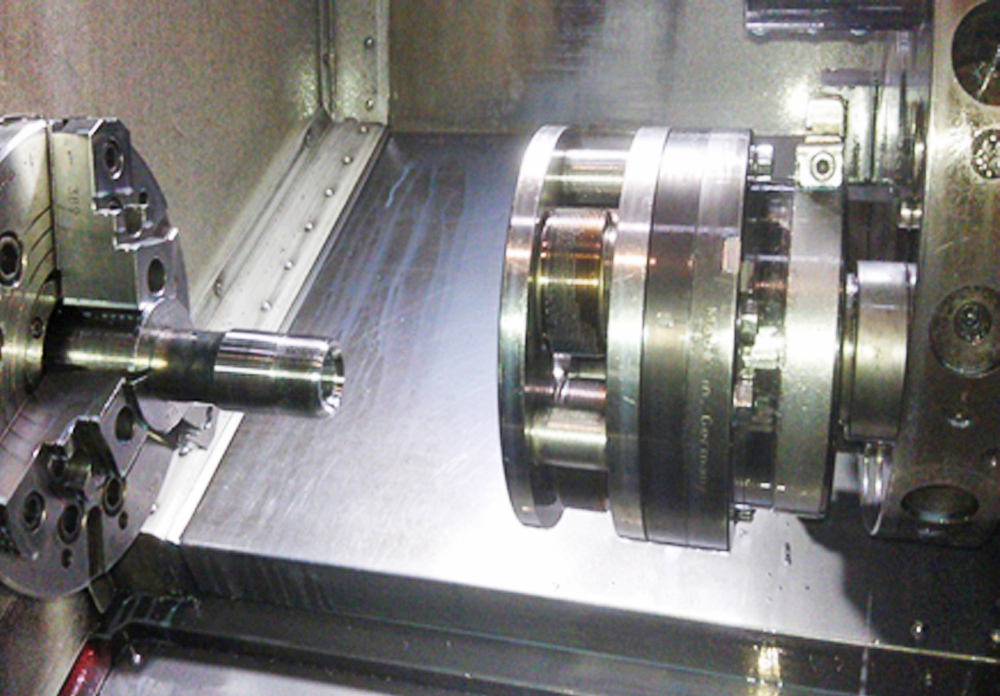

Manufacturing facility of ELKAM is equipped with up-to-date tools and CNC machines.

- Facility surface is 17062 sq. m.

- Surface of warehouse of finished products is 738 sq. m.

- There are 42 machines.

- There are 650 employees.

- Manufacturing volume is 12 thousand pumps per year.

For manufacturing of pumps operating elements we apply up-to-date and unique methods of hardening: ion-vacuum nitriding, carbon nitriding, magnetron sputtering, chrome plating, cold radial forging.

All our products pass 100% quality control.

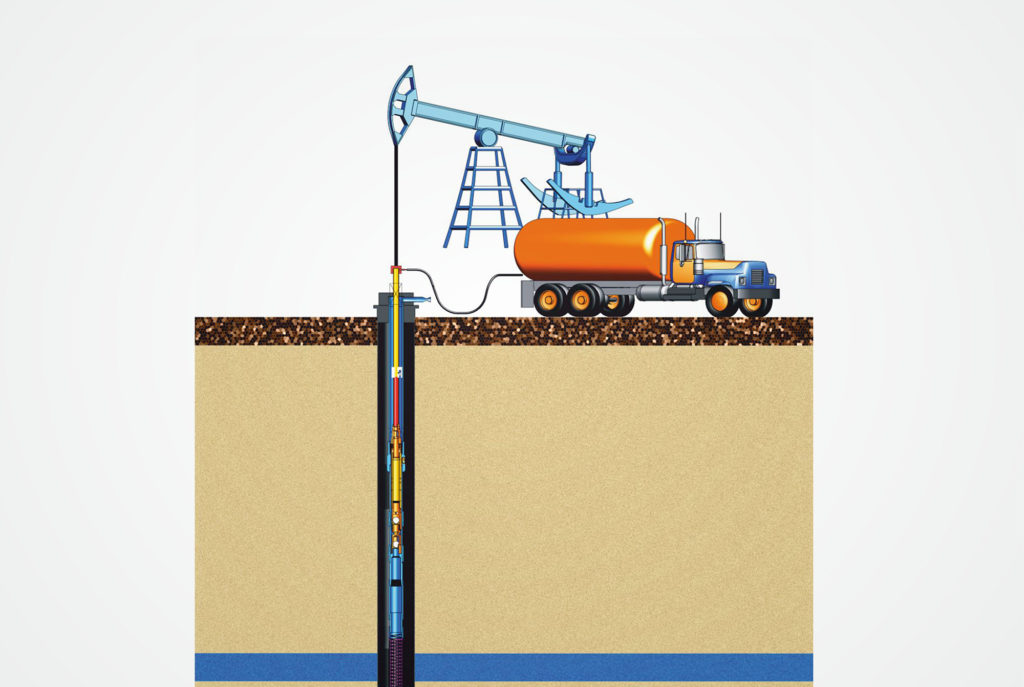

Well warm-up and flushing

Hollow rod warm-up and flush equipment is used for hot flushing of oil wells operated by submersible sucker rod pumps and complicated by asphalt-resin-wax deposits (ARWD) where tubes are used to build production string and hollow rods with couplings used as a heat transfer agent duct. Equipment is mounted once together with pump during well servicing and left in well. There is no clogging of pump operating elements during washover of tubing string.

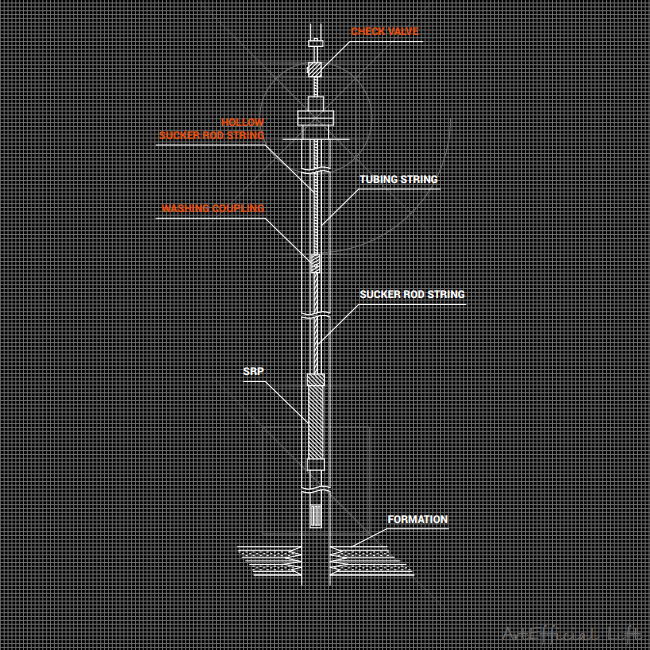

Deparaffination equipment for SRP

The equipment is designed for tubing heating and flushing during SRP operation.

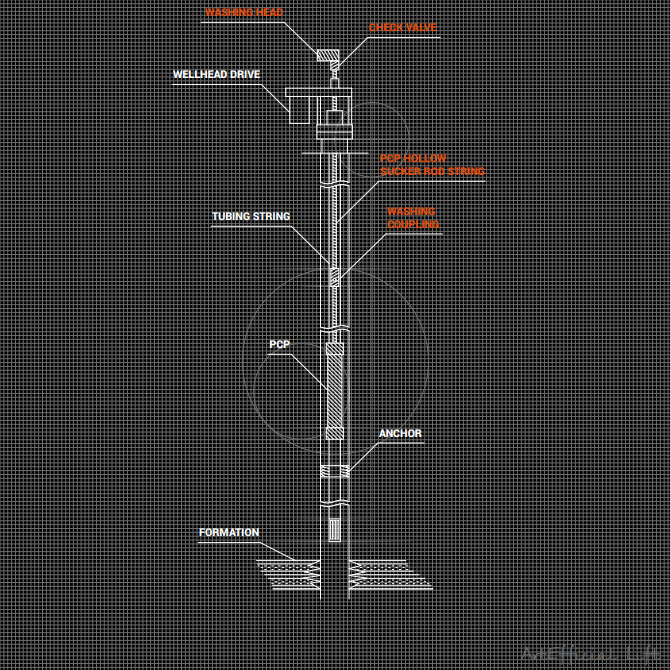

Deparaffination equipment for PCP

The equipment is designed for tubing heating and flushing during PCP operation.

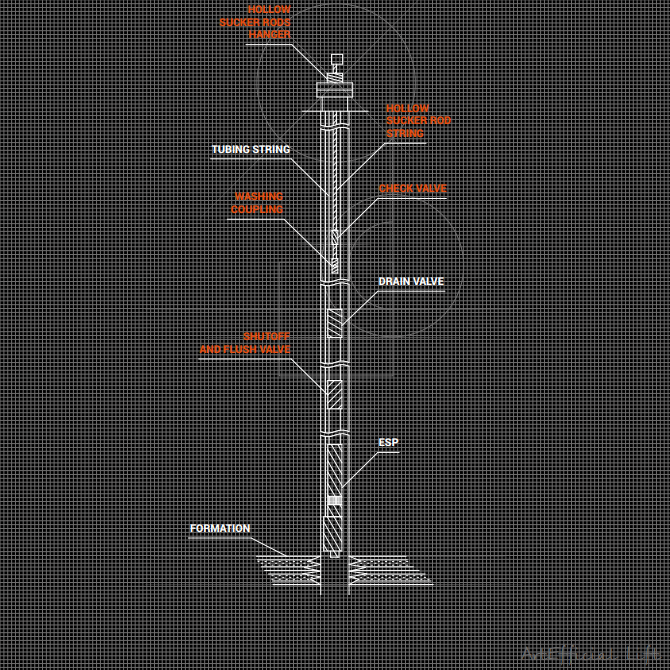

Deparaffination equipment for ESP

The equipment is designed for tubing heating and flushing during ESP operation.

Oil production equipment for simultaneous seal of leakage interval

Technology and set of equipment for simultaneous seal of leakage intervals are used for oil production from old wells with flow rate up to 75 m3/day and defected casing (leaking) without making expensive workover. The main advantage of equipment application is saving time and money for workover of wells with defected casing. Equipment set can be mounted during well servicing with application of conventional tools.

Hollow sucker rods

Manufacturing of hollow sucker rod starts with pipe workpiece. Manufacturing volume is 41 000 of hollow sucker rods per year.

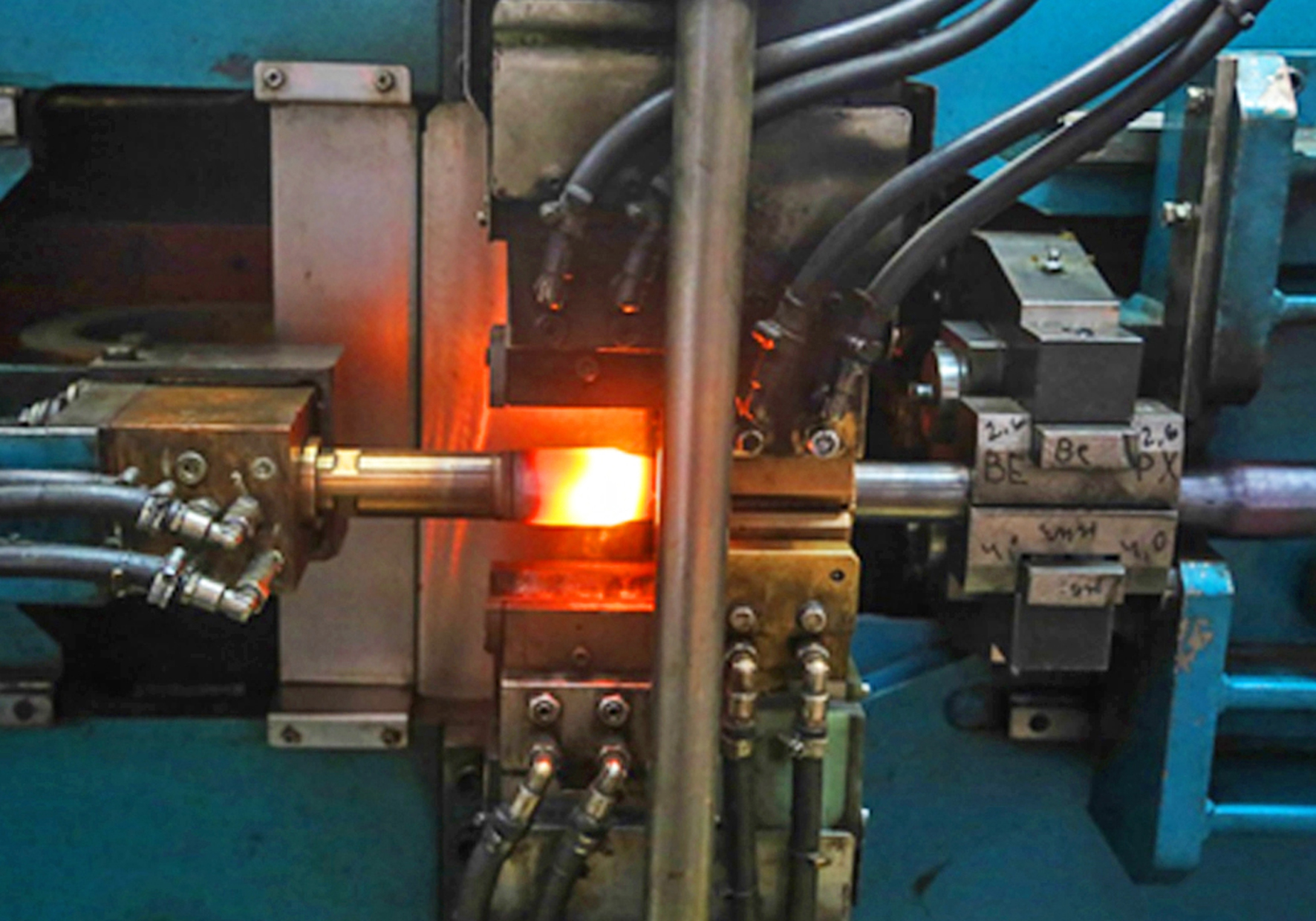

Sucker rod head is hot shaped. Metal workpiece is placed to a special and unique in its way purpose-made machine, «needled» and widened under high temperature and pressure.

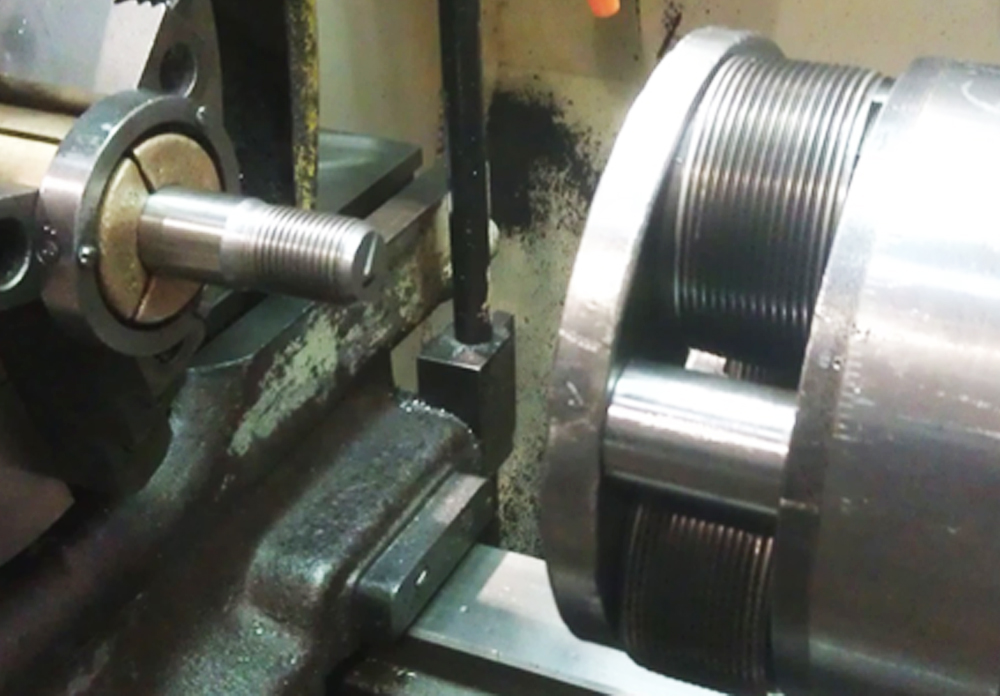

Thread of sucker rods is rolled on – no thread cutting. It allows avoiding sucker rods breaking because of thread failure.

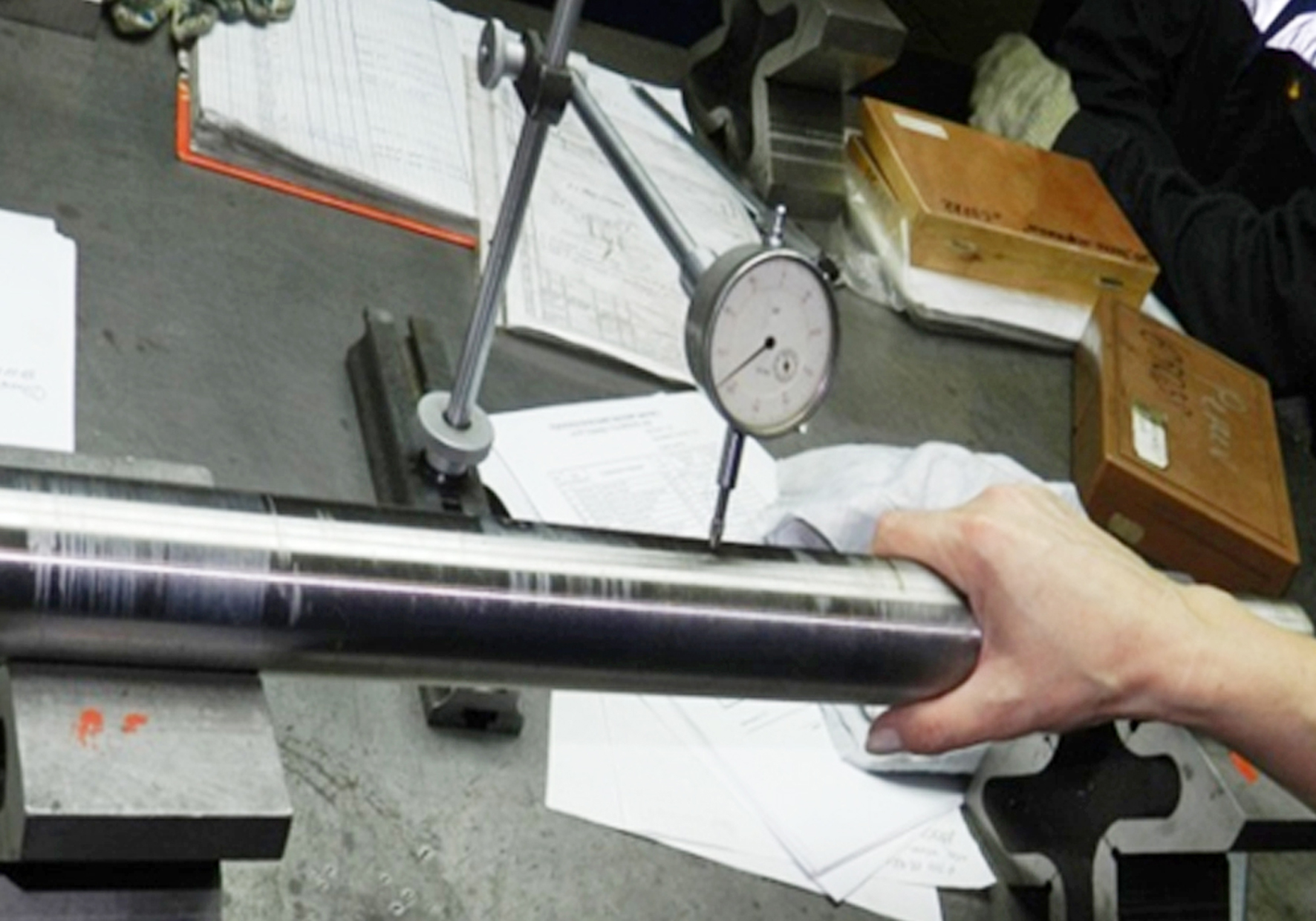

During quality control besides geometrical parameters our specialists check threads and tightening torque of each coupling.

The final stage of sucker rod manufacturing is tension testing. After that sucker rods are conserved and packed for the future shipping or storing.

High Gas-Oil-Ratio

For production of oil with high GOR ELKAM provides the following solutions: 1) specialized two-stage sucker rod pump with additional top valve which allows to shut off hydrostatic fluid column from discharge valve, thus creating low-pressure chamber above the travelling valve; 2) tubing sucker rod pump of THM-G (NNSHG) type plunger of which is made as valve plunger with plate-type seal of hard alloy travelling valve; 3) sucker rod pump with gas discharge tip which is used for the purpose of positive opening travelling valve; 4) gas separator designed for efficient high-capacity formation fluid gas separation.

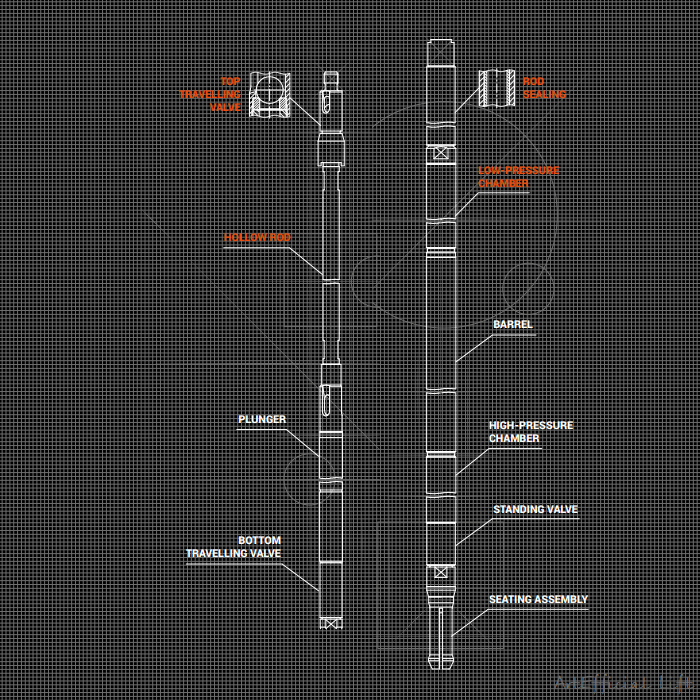

Differential gas pump

Differential gas pump is used for production of high GOR crude to reduce or eliminate negative impact of gas on downhole equipment.

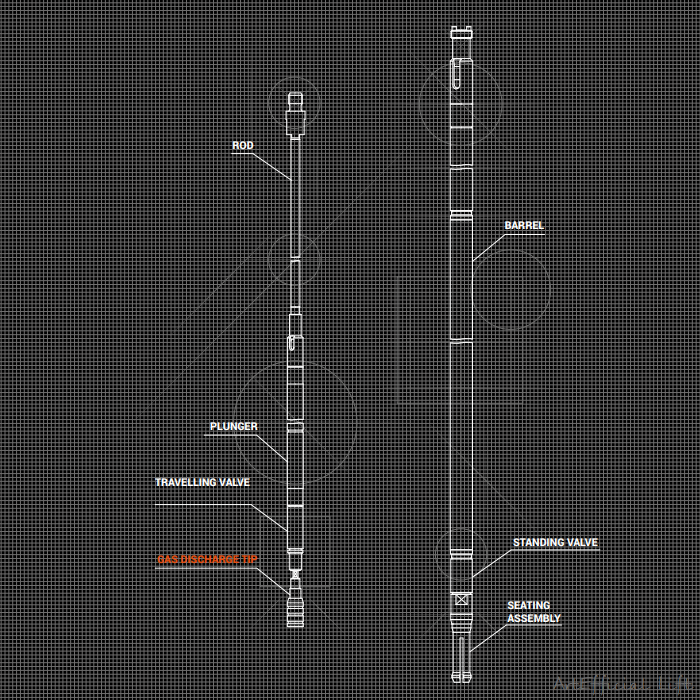

Sucker rod pump with gas discharge tip

Gas discharge tip increases sucker rod pump flow rate in high GOR environment.

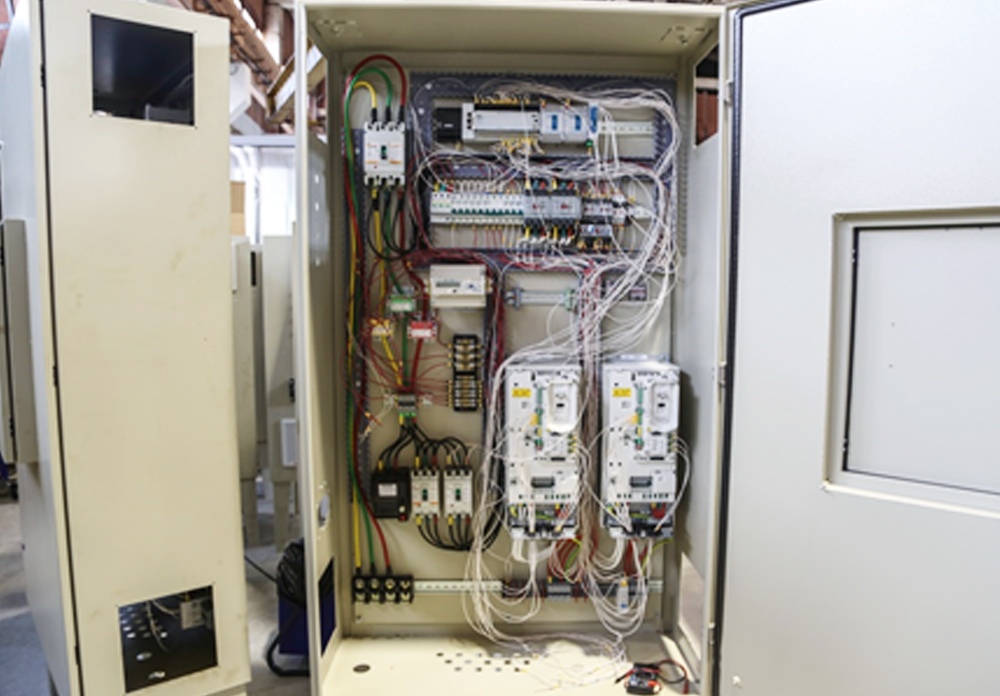

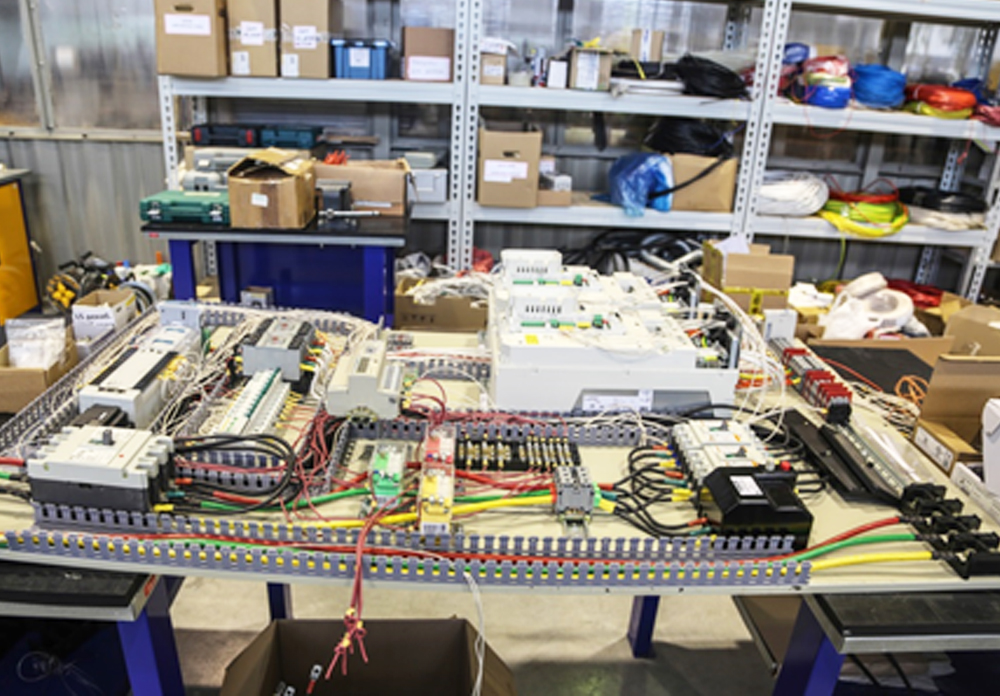

Control boxes manufacturers

The first stage of control box manufacturing is purchasing of the necessary components. We work only with approved suppliers-partners – manufacturers of required components. Mainly our control boxes are completed with driven equipment and controllers by ABB, an official certified business partner of our company.

At the final stage of control box manufacturing we perform electric load testing with the usage of available on the territory of our factory well and relative equipment. All the installation works are performed by qualified personnel completed training in specialized educational centers. For all control boxes supplied to our Customers we provide guarantee, servicing and unlimited technical support.

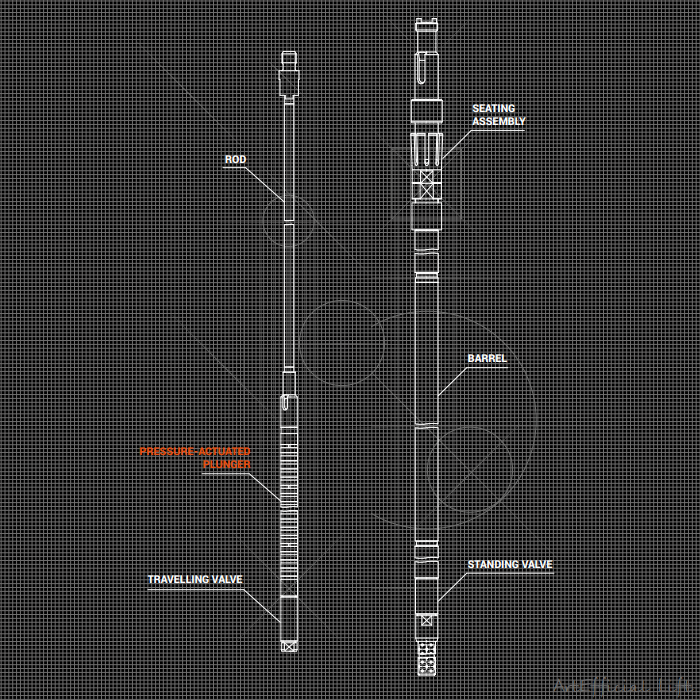

High solids content

For efficient oil production in conditions of high solids content we manufacture and supply specialized pumps with “Sandshaver” plunger, wiper seal plunger or plunger with sealing rings; as well as SRP and ESP accessories: gas-sand anchors, filters, pipe scale collectors. These accessories increase efficiency of oil production unit operation, significantly decrease negative influence of solids on operating pump elements and as the result increase oilfield equipment runlife (prevent blocking and operation stopping).

RHAMZes Pump

Production of fluid with high solids content, up to 30% higher reliability in comparison with conventional SRP.

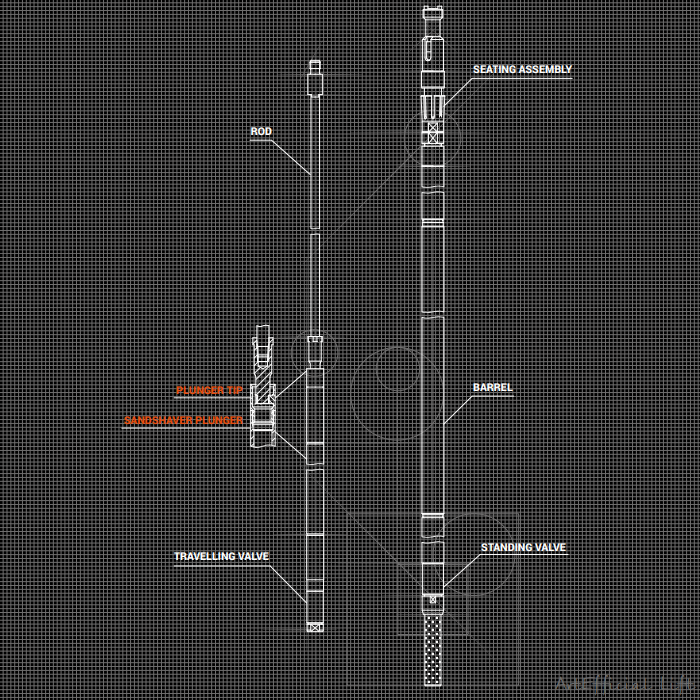

Sandshaver pump

Sandshaver pump significantly mitigates solids influence on operation of downhole equipment and increases its runlife.

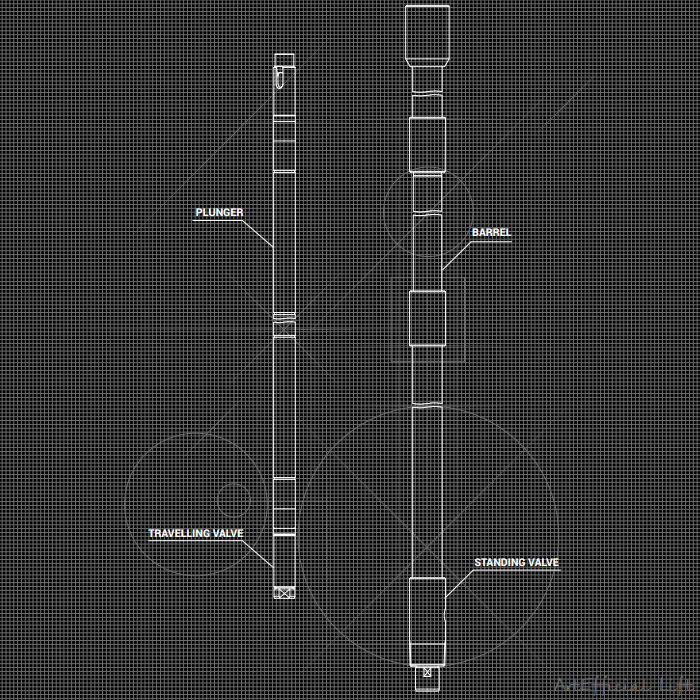

Short-barrel pump

Combination of long plunger with short barrel significantly increases reliability of sucker rod pump operation in high sand production wells.

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia