Control box drive sucker rod pump set

For optimization and automatization of oil production process and also for decreasing of expenses for power consumption our company develops and manufactures control boxes which are able to ensure full protection of the whole pumping set preventing accidents. Also they ensure full independence of operations even in the simplest package. ELKAM’s line of control boxes include VFD and intellectual control boxes with the ability of connection of additional control devices (telemetry systems; sensors of pressure, vibration, temperature, rod position; etc.)

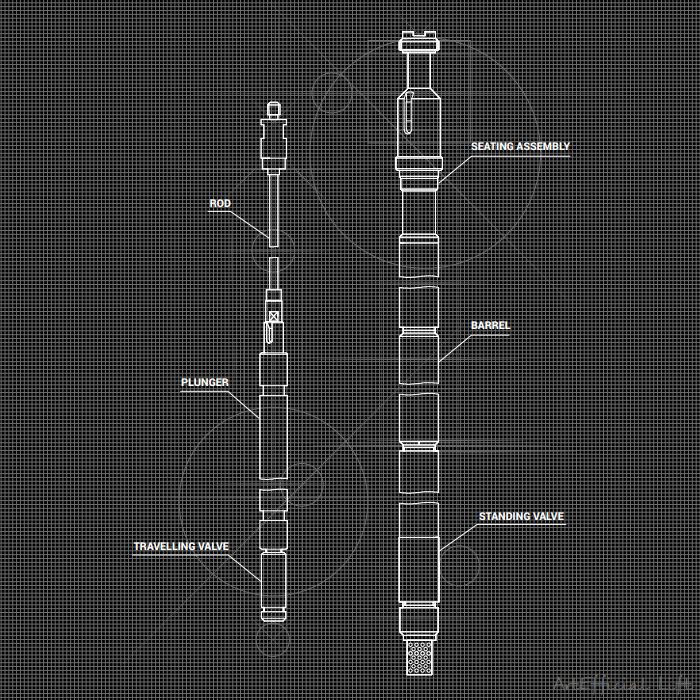

Insert SRP

Insert SRPs are lowered inside the tubing as an assembled unit with sucker rods. They are anchored in mechanical, cup or friction type seating nipples. Depending on the barrel type (thin/heavy wall, travelling/non-travelling) and seating nipple placement (top/bottom) these pumps have special designations: according to Russian standard GOST: NB1B and NB2B , according to API 11-AX: RHAM, RHBM, RWAF, RWBF, RHTFS, RHAC, RHBC. Insert pumps manufactured by ELKAM have nominal size from 1 1/16” up to 2 1/4” and can be customized according to the customer’s requirements.

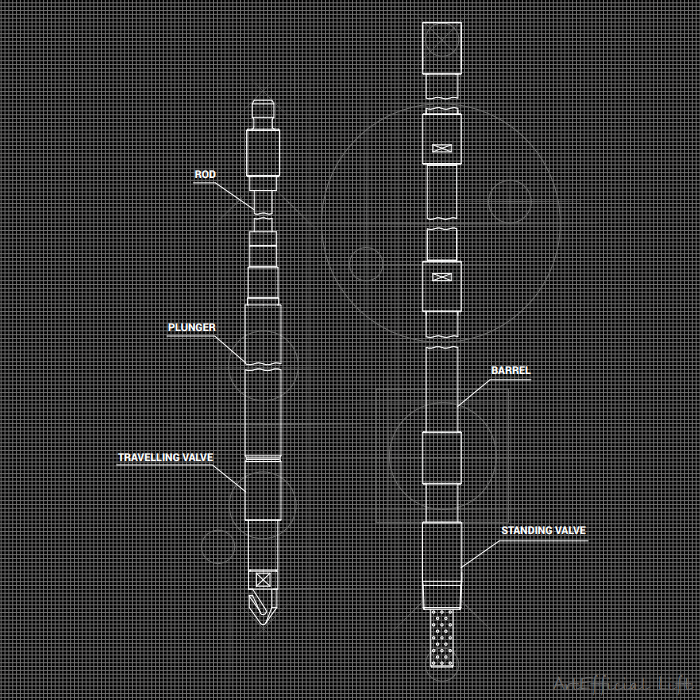

Insert sucker rod pump

Insert sucker rod pump is set in borehole on sucker rod string and fixed in tubing string with the help of seating assembly, which ensures leak-tightness.

Tubing SRP

ELKAM manufactures tubing SRPs with nominal size from 1 1/4″ up to 4 3/4″. These pumps can be fitted with retrievable plunger (catcher) or drain valve (membrane or with breakable plug). Depending on availability of catcher and type of drain device tubing SRPs have the following denomination: according to Russian standard GOST – NN2B, NNSh, NNB, NNBA, according to API 11-AX – THM-S, THM, THC. At customer’s order pumps can be completed with barrels, plungers and valve pairs of various materials and additionally fitted with on/off tool, gas-sand anchor or sand prevention pipe.

Tubing sucker rod pump

Tubing sucker rod pump barrel is set in borehole on tubing string to determined depth, while plunger is run-in separately on sucker rod string or together with pump connected by on-tool.

Specialized SRP

Specialized sucker rod pumps are insert and tubing SRPs with nominal size from 1 1/6” up to 4 3/4″ specially developed for complicated oil production conditions when application of conventional SRPs becomes inefficient or impossible. Presently we offer solutions for high GOR; high solids content; high viscosity and emulsions; asphalt-wax-resin deposits (ARWD); deviated, low and deep wells.

Adaptation of young specialists

Any new employee needs time to integrate into the company and get used to the new place of work

For quick and efficient adaptation we use a mentoring method

A young specialist is assigned an experienced, qualified and competent employee who acts as a mentor and transmits the knowledge necessary for the quality performance of the work to the novice and shares his practical experience

Each new employee has its own mentoring, which involves not only the introduction to the position, but also the study of the production cycle of the factory

Today we’d like to share with you some photos and videos how young specialists get acquainted with the production cycle of oil production equipment

We have started 2021 with set sights

Last year brought us lots of “surprises”, rapidly changed our plans, taught us to find solutions and make decisions quickly, and be more attentive to each other

Yesterday our team together with business coach Alexey Sementsov had been working on finding opportunities for greater professional efficiency, as the result we learned how to form useful habits in sales

Inspired, active, with positive emotions and new knowledge we have started 2021. Let’s go!

Summing up the results of 2020

There are only a few days left until the new year, and summing up the results is an integral part of the company’s development strategy

You can sum up the results in the traditional and usual way – in the form of written reports and plans from each employee

But we always try to find new non-standard solutions in everything, so our summing up was held in the format of a training session outside the company’s walls

We analyzed our strengths and weaknesses, determined what hindered us in achieving the goal, and what helped us, what team skills we acquired and how we can maintain and develop them in the new year

Now we are fully prepared for super results and new victories

ELKAM at Almetyvsk triathlon

As You know, ELKAM is not ready to rest

On the 8th of August in Almetyevsk city, the Oil Capital of the Republic of Tatarstan, the Russian Triathlon Championship took place as part of the selection for the European Championship. “Almetyevsk Triathlon” has always been considered the prestigious and main competitions of the country in the season, that’s why the strongest participants in this discipline gathered there

Teams from TATNEFT, ROSNEFT, as well as some small independent oil production companies of the Russian Federation took part in the competition. The total number of participants was 340 people, including our specialists

According to the results of the relay race, ELKAM team overcame 3 stages (750m of swimming, 20 km of cycling, 5 km of running) in 1 hour 2 minutes and 1 second, showing the best result among the participating teams and setting a new record for the Almetyevsk triathlon track, improving the previous result more than 3 minutes

Almetyevsk hosted the Russian Championship for the second time and showed an excellent level of organization and running the competition

ELKAM in rating of reliable partners

Expert analysis which includes analysis of dynamics and structure of business, analysis of financial solvency, scoring, analysis of business activity and assessment of efficiency of usage of company resources was carried out among 531 companies of Privolzhsky Federal District

According to the results of an expert assessment of the financial and economic indicators of the companies in the industry (OKVED 28.12), ELKAM was included in the list of recommended companies and, according to the ranking, was included in the Rating of reliable partners

For a significant contribution to the socio-economic development of the region, priority in the industry, as well as good results within its segment, ELKAM was recommended for the regional program “The Best Enterprise of the Industry 2019”

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia