Quality control

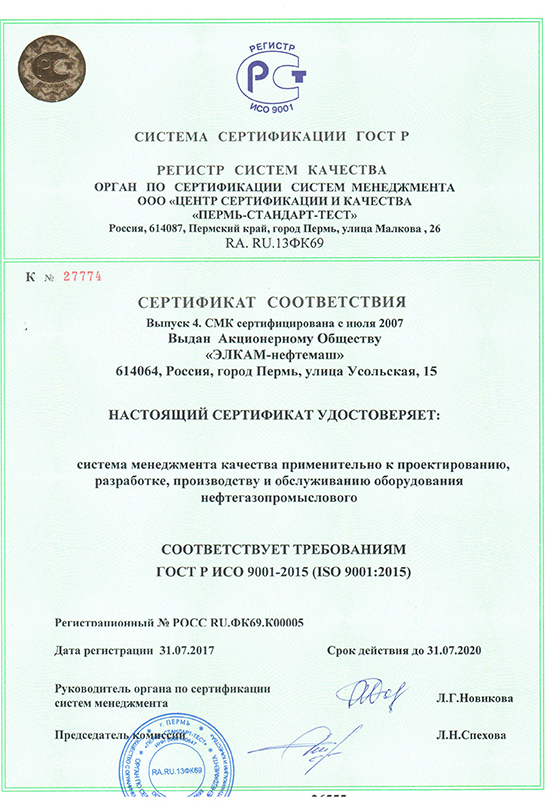

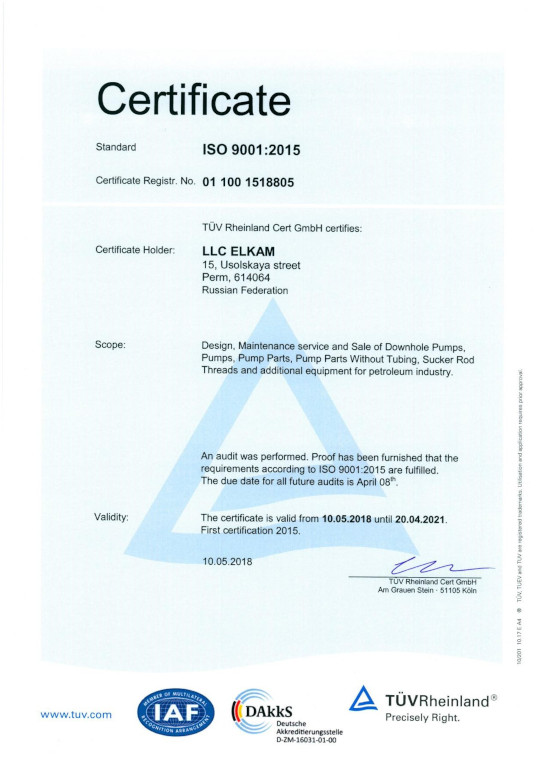

Our company has strong quality management system (QMS) both referring to manufacturing products and company management, including all the departments. QMS referring to the main activity areas of ELKAM corresponds to the requirements of ISO 9001 standard since 2007 and successfully passes regular inspections. Quality strategy of ourcompany is aimed at constant improvement of business processes in all the activity areas using high-efficient advanced methods. Our quality policy is aimed at improvement of quality of manufacturing products, increase of Customer’s satisfaction and improvement of quality management system. In 2011 we got ISO 14001 certificate.

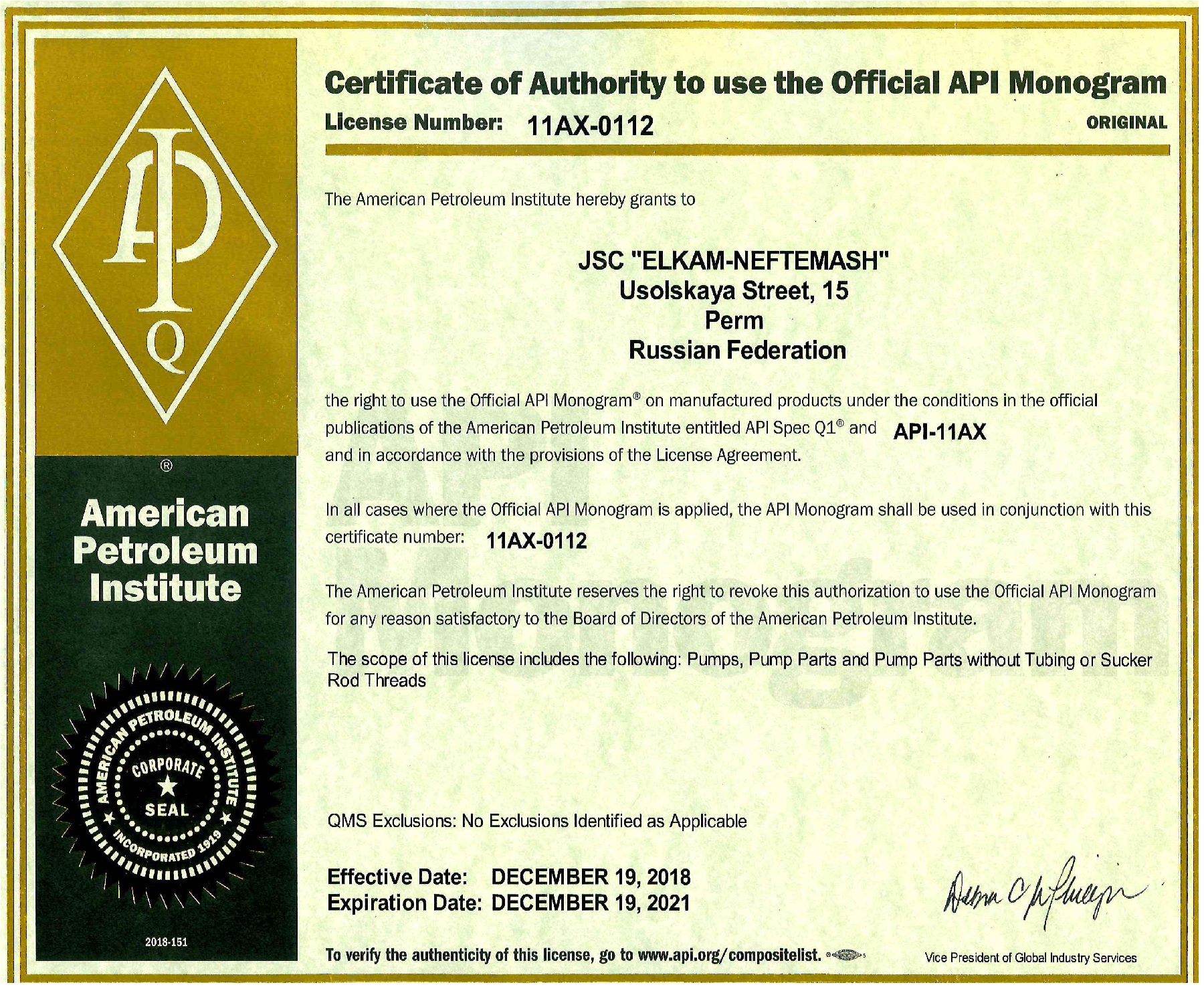

In 2012 we successfully passed the first certification audit for compliance of quality management system of our company with the standards of American Petroleum Institute – API Q1. That time we got a license for stamping API-11AX monogram. In December of 2018 again ELKAM proved compliance of QMS and manufacturing goods with API standards. Attestation was successfully passed; the license was prolonged up to the end of 2021. In 2015 we successfully passed certification audit for compliance with the requirements of occupational health and safety management system according to OHSAS 18001 standard.

To achieve high quality of manufacturing products our quality control specialists perform all the types of control: incoming, operational and final. These types of control are performed at all the stages of manufacturing. Approval testing is performed before quality control inspector, the results are recorded in test log and supporting documents for the products.

Approved goods together with supporting documents are delivered to the warehouse of finished products where according to technical documents they are conserved, checked for completeness, packed and prepared for shipping to the Customer within the contract terms.

Our personnel regularly complete training on QMS and have individual certificated confirmed their competence and professionalism.

In 2019, our company passed the procedure of voluntary certification of “Made in Russia”. This program guarantees the integrity of certified manufacturers, the safety and quality of their products. Thanks to the strict rules of the “Made in Russia”, only safe and reliable products that meet high international standards are peer reviewed with a positive result.

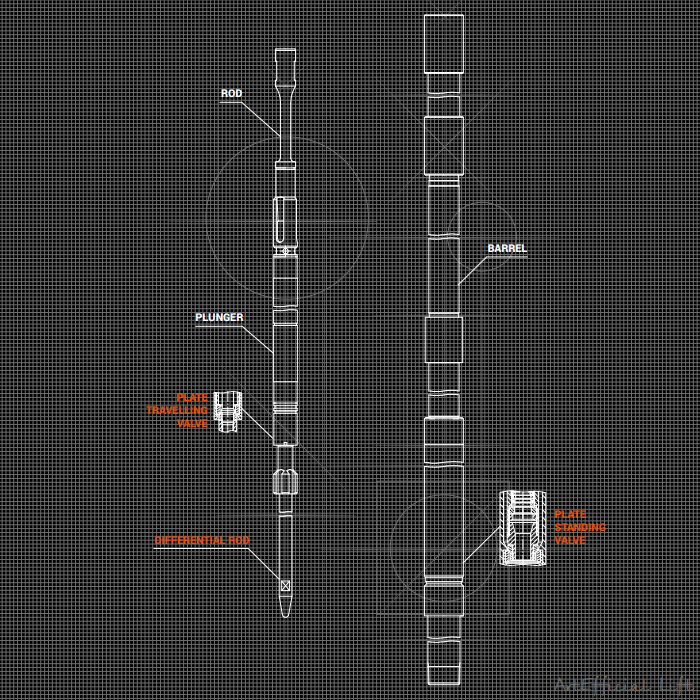

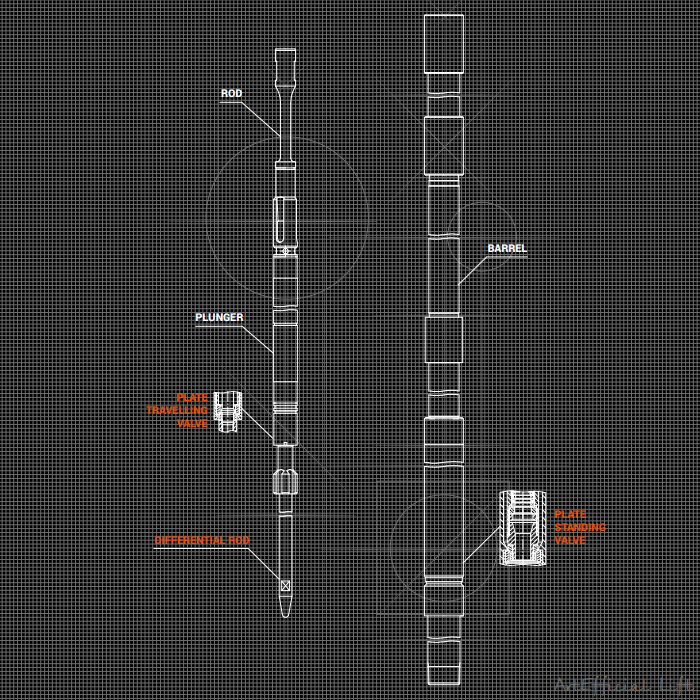

Viscous oil

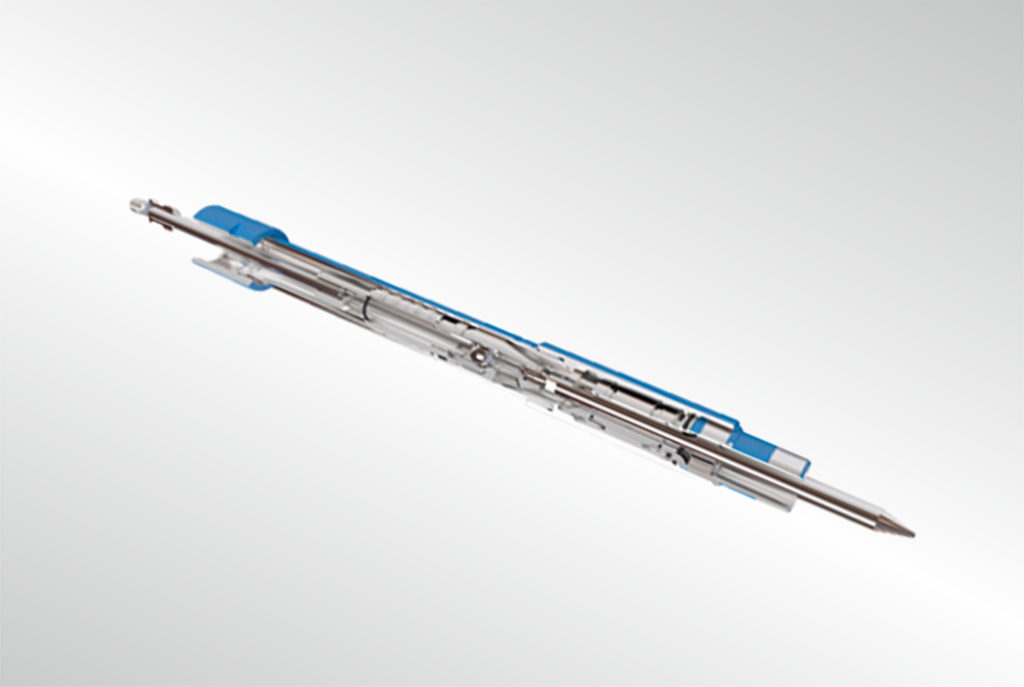

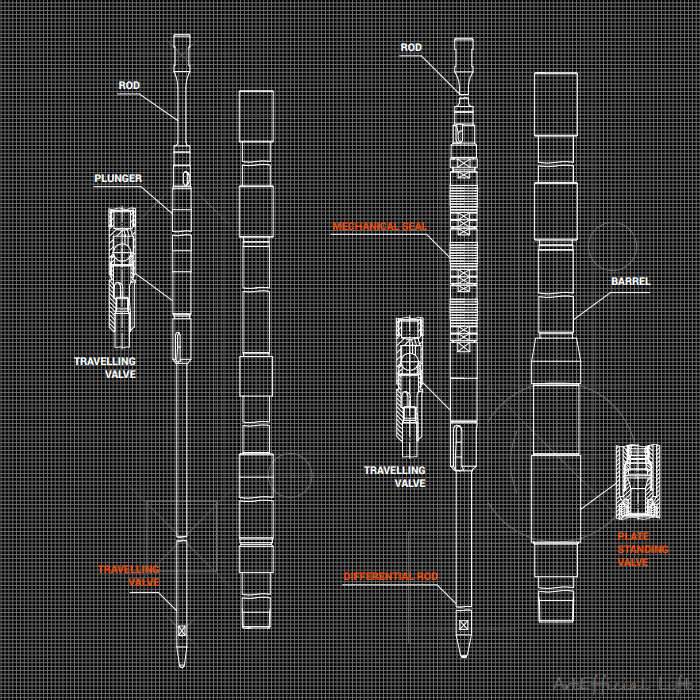

The most widespread problem of viscous oil production is leakages which appear as valves cannot be closed on time. As the solution of this problem our specialists developed specialized sucker rod pump SPeaR. It has the nominal size from 1 3/4″ to 2 3/4″, plunger stroke length up to 6000 mm (19,7 ft), mechanical sealing with eccentric rings and positive opening plate-type standing valve. Besides SPeaR pump is operated together with flexible cable rod for oil production from deviated wells.

SPeaR Pump

SPeaR differential pump is used for production of highly viscous oil and emulsions, prevents floatation of sucker rod string and improves pump efficiency.

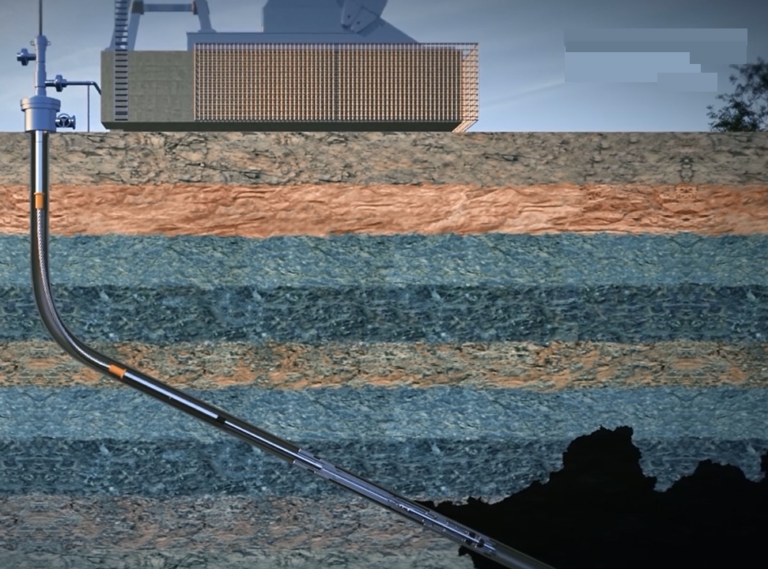

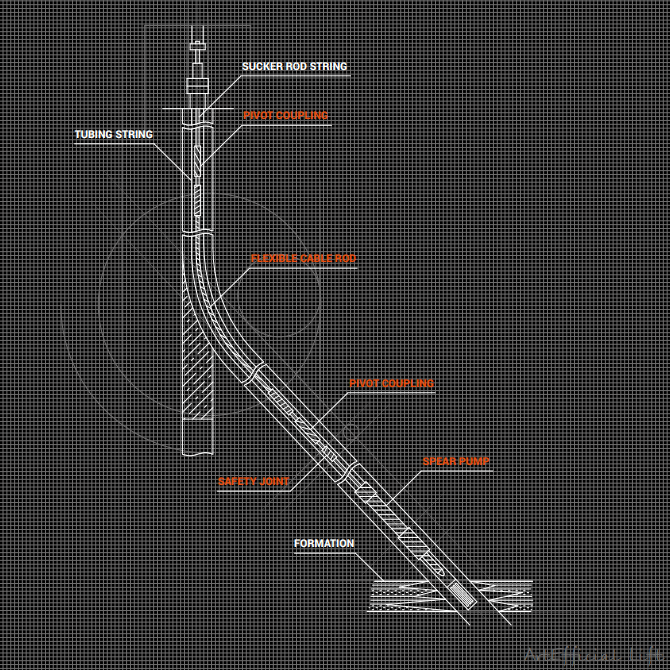

Lateral holes and deviated wells

Equipment set with flexible cable rod (specialized sucker rod pump SPeaR + flexible cable rod) is used for operation of wells with lateral holes of small diameter (pump is located directly in lateral hole below dynamic fluid level) as well as deviated wells for decrease of friction between sucker rods and tubing string. Lateral hole deviation angle at pump setting place is up to 62 degrees. Pump setting depth is up to 2200 meters. This equipment avoids problems with rod couplings joints (loose or tighten connections; swabbing effect; breakings because of ends defects and corrosion).

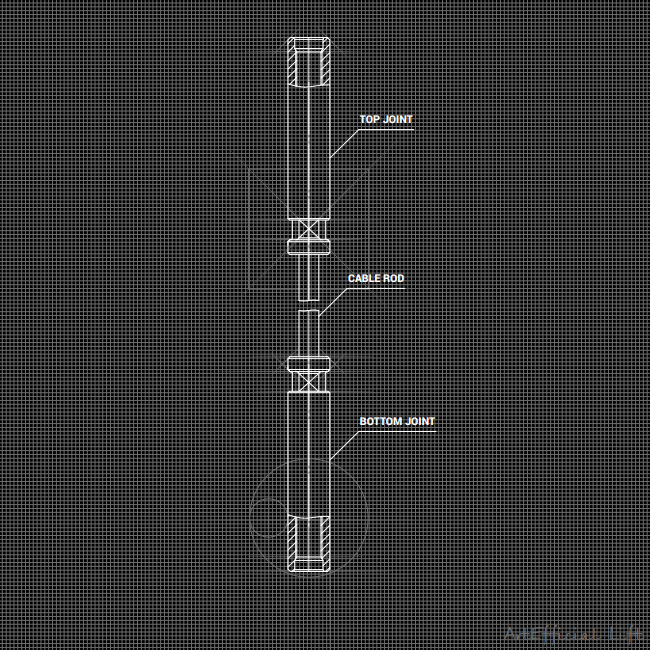

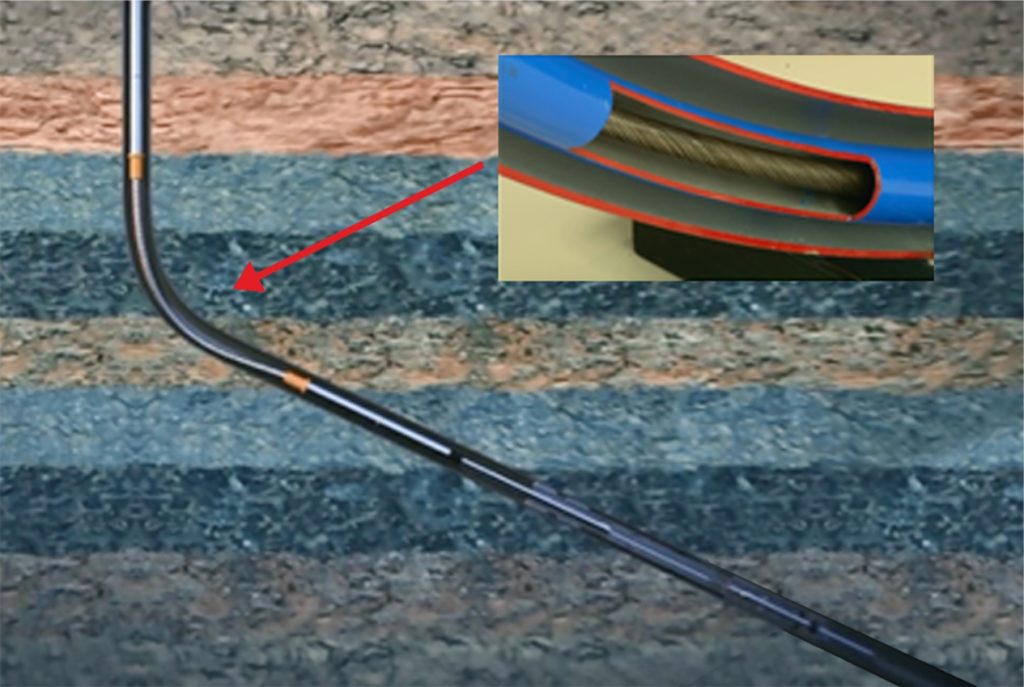

Flexible cable rod

Flexible cable rod is designed for operation of highly deviated wells and small ID sidetracks.

SPeaR pump with plate valves

SPeaR pump with plate valves provides operation in wells with highly viscous oil, deviated wells up to 90° and sidetracks. It is also widely used in combination with flexible cable rod for highly deviated wells.

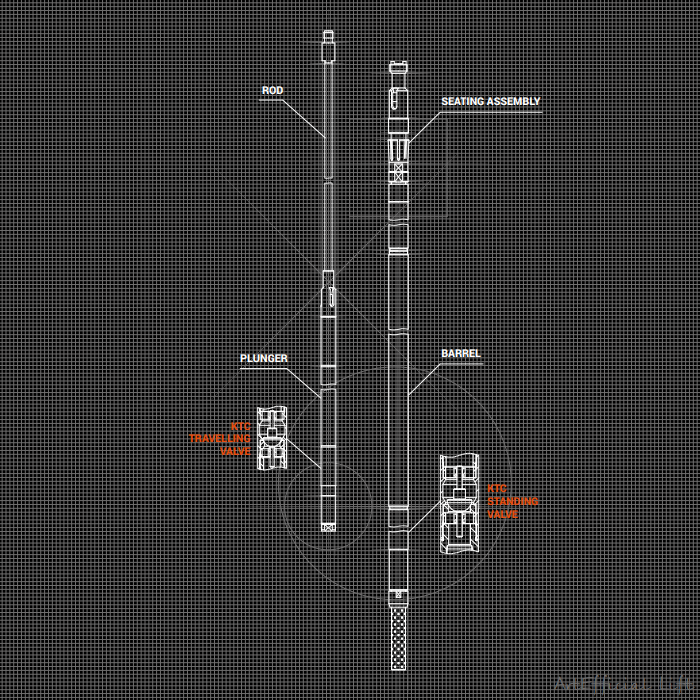

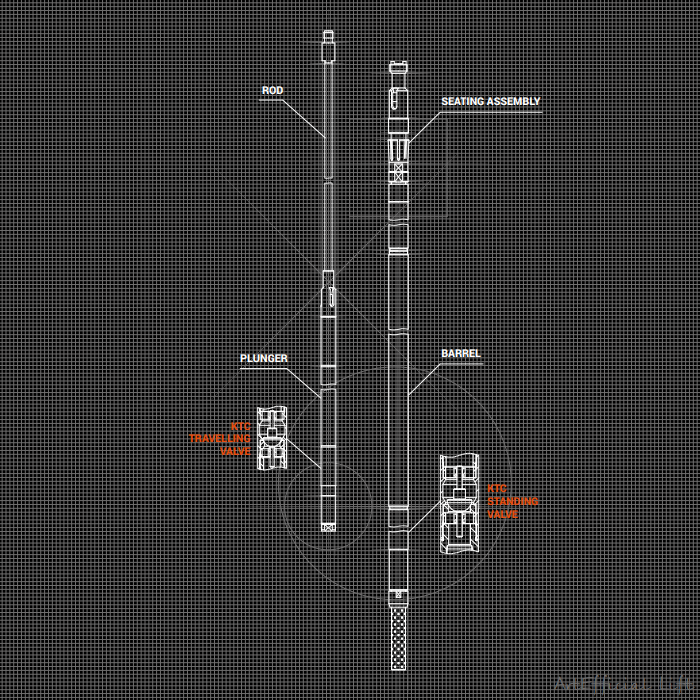

Sucker rod pump with KTC hemisphere valves

SRP with KTC hemisphere valves provides oil production in wells with deviation angle up to 70 degrees and high viscosity oil.

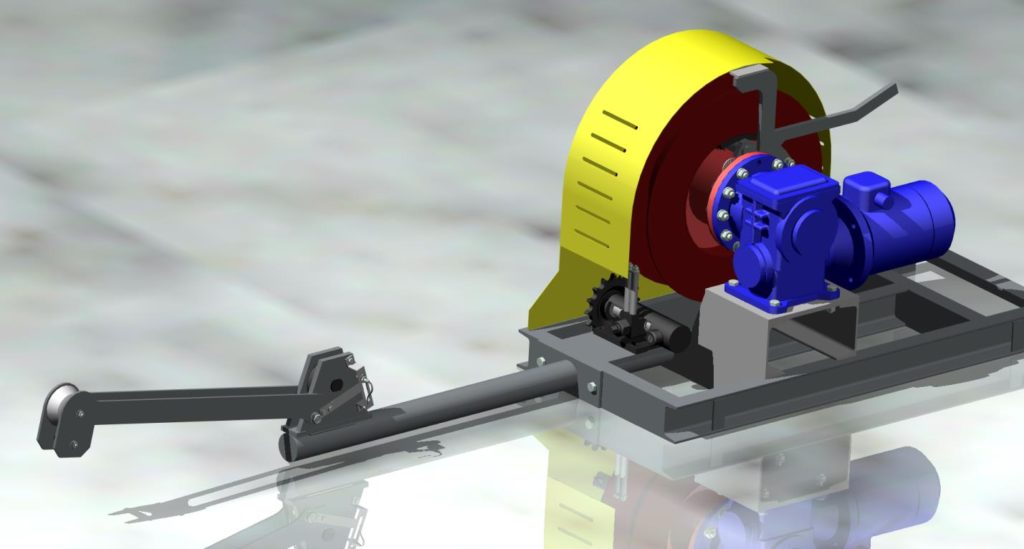

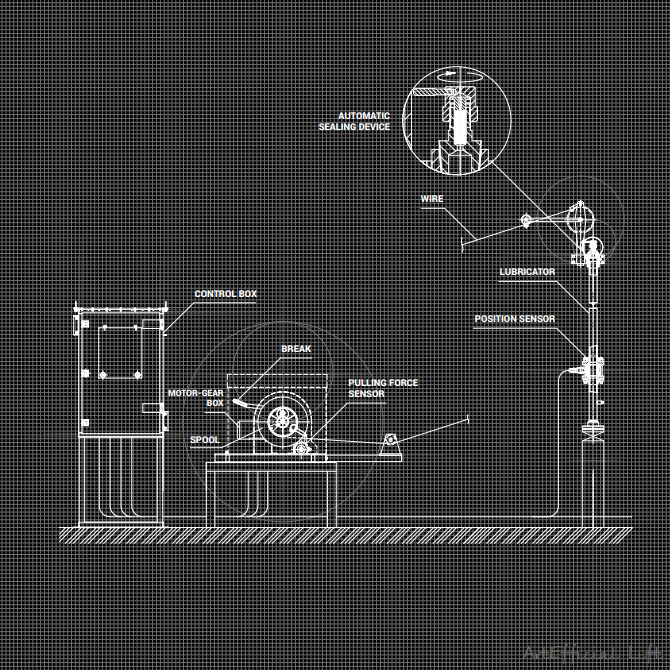

Well deparaffination unit (WDU)

Well deparaffination unit (WDU) is used for mechanical cleaning of oil-well tubing inner surface from asphalt-resin-wax deposits (ARWD) in the course of oil recovery by ESP and natural flow. WDUs differ by the way of setup on wellhead – they can be placed on wellhead using lubricator or on basement at 25-30 meters from the wellhead. WDUs also vary on control type – they can be semi-automatic or automatic. ELKAM supplies both onshore (including mobile) and offshore well deparaffination units.

Well deparaffination unit

Onshore semi-automatic and automatic, wellhead and cluster, mobile and offshore modifications are available.

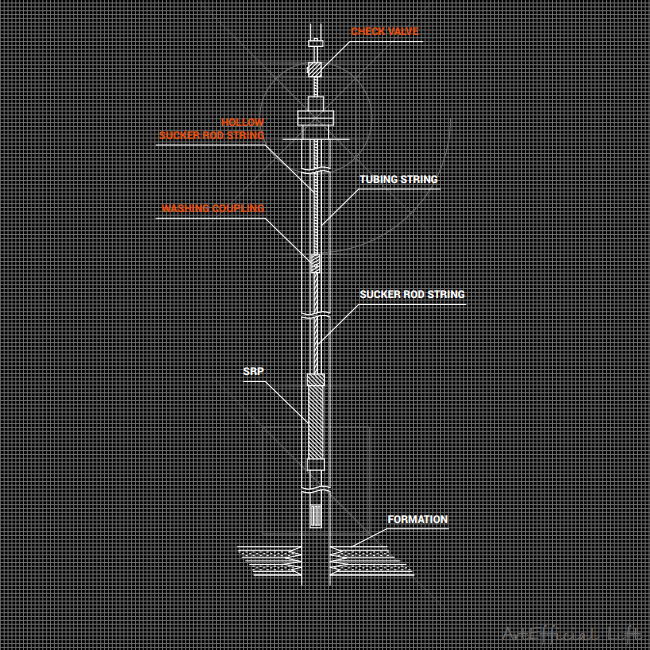

Deparaffination equipment for SRP

The equipment is designed for tubing heating and flushing during SRP operation.

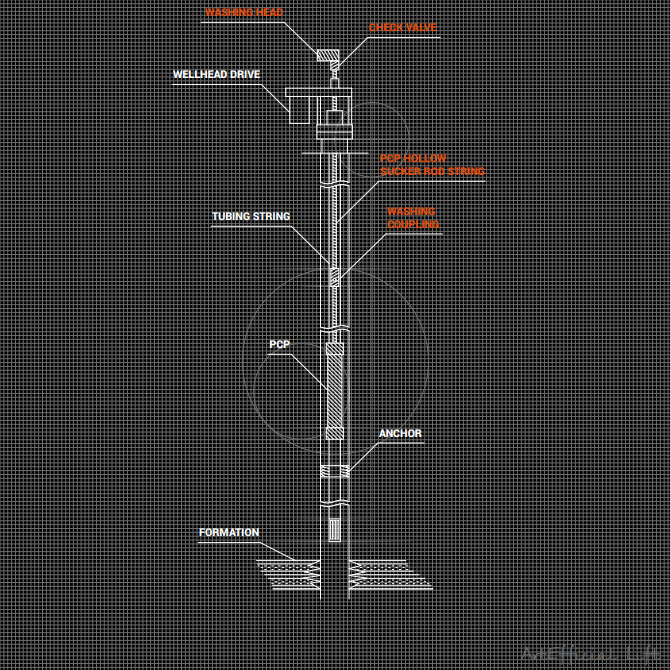

Deparaffination equipment for PCP

The equipment is designed for tubing heating and flushing during PCP operation.

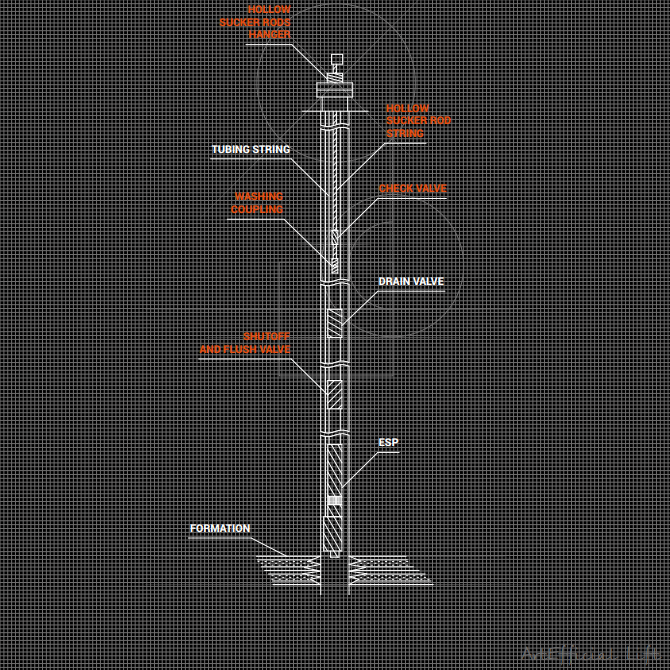

Deparaffination equipment for ESP

The equipment is designed for tubing heating and flushing during ESP operation.

Electric submersible pump

Electrical submersible pump (ESP) for oil production has a multi-stage design. Each stage consists of the following parts: body, shaft, stage rotors, top and bottom guide bearings, centerline support, head, base. ESPs design differs by materials of operating pump parts, body parts, friction couple; configuration and quantity of guide bearings.

Sucker rod displacement pump NNVD

Sucker rod displacement pump NNVD differs from conventional one by its design – it has a plunger with hollow rod and leak-proof seal of hollow rod. In contrast with conventional SRP plunger of NNVD has no impact of tubing fluid column, fluid from plunger flows in hollow rod but not in the space above the plunger. If compare NNVD pump with conventional SRP or ESP it has the same drive, quantity of strokes and flow rate but its setting depth is up to 2700 meters.

Protector

Protector is a device designed to prevent entering of formation fluid into inner cavity of electric motor and oil leakages (serves as sealing); to transfer rotary moment to the shaft of ESP; to accommodate temperature expansion of oil volume inside inner cavity of electric motor (surplus of oil is thrown out to annular space of the well through the valves) and to equalize pressure inside engine cavity with pressure of formation fluid in a well.

High-rate SRPs

ELKAM manufactures and supplies specialized pumps for high rate wells. Dual operation pump: having equal size and flow rate as conventional tubing pump Ø70 mm it ensures decrease of maximum impacts on beam pumping unit and specific energy consumption for 30% by means of energy of pulling down rods. “Tandem” pump is specialized SRP with two plungers, hollow rod and plate type valves. It can operate in casing of small diameters from 114 mm and has smaller overhaul dimensions in comparison with conventional tubing pump of Ø70mm.

Downhole motor

Downhole motor is ESP drive used for conversion of electric power supplied across the wire to mechanical power of pumps rotation. This is a motor of special design which poses induction, three-phase, bipolar, motor. It is full of low viscosity oil which serves as lubricant for rotor bearings. Besides it transfers heat to engine body washed by production fluid stream.

Flexible cable rod Esp alternative

Flexible cable rod equipment set is used for oil production from horizontal wells or rat holes with casing of small diameter and drift angle up to 90 degrees. Equipment set consists of sucker rod string, flexible cable rod, crossover coupling, specialized sucker rod pump SPeaR and slot filter. Usage of cable at the interval of intense drift deviation allows avoiding friction between tubing string and rods due to less friction force.

Flexible cable rod set

Flexible cable rod set increases pump setting depth in sidetrack and provides additional oil production.

SPeaR pump with plate valves

SPeaR pump with plate valves provides operation in wells with highly viscous oil, deviated wells up to 90° and sidetracks. It is also widely used in combination with flexible cable rod for highly deviated wells.

Sucker rod pump with KTC hemisphere valves

SRP with KTC hemisphere valves provides oil production in wells with deviation angle up to 70 degrees and high viscosity oil.

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia