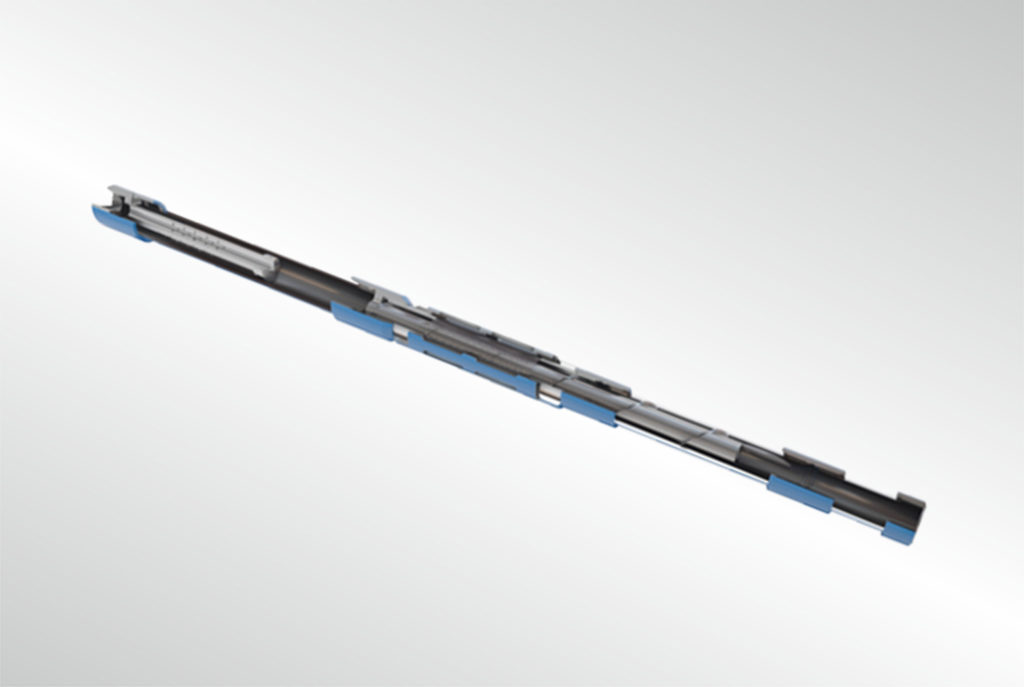

Sucker rods

ELKAM supplies 5/8″, 3/4″, 7/8″ and 1″ sucker rods manufactured in accordance with API-11B standard of K, C, D and D spec. grades. We developed a unique product – sucker rod ShNK-29 of D grade with coupling diameter 54 mm which can be applied with 2 7/8” tubing by contrast with standard sucker rod 29. It allows to produce oil from the depth over 2500 meters.

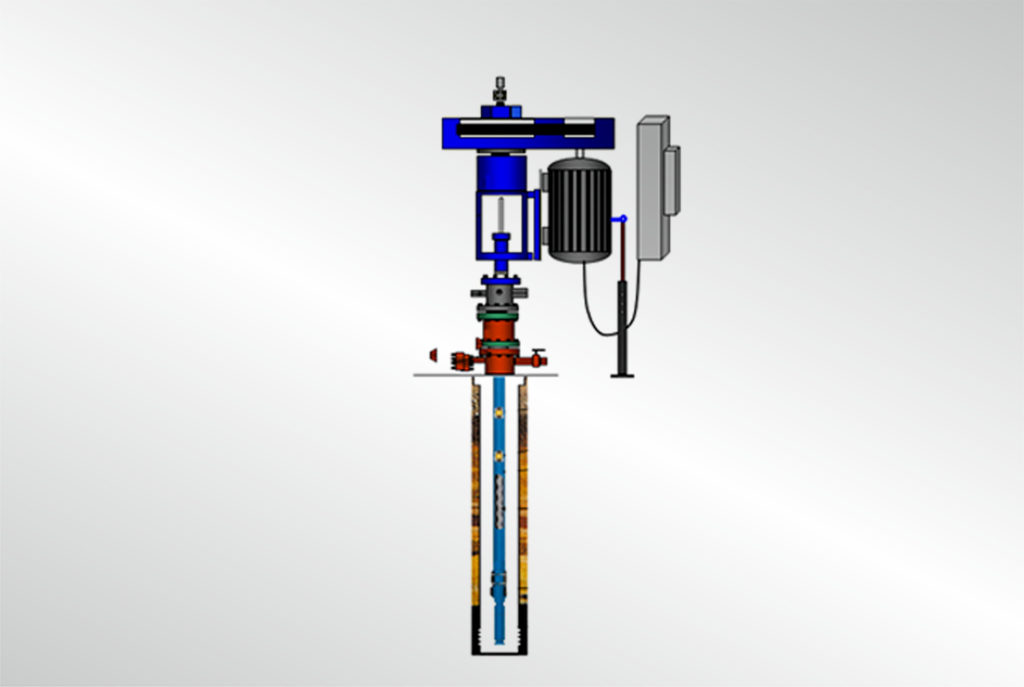

Surface drive

Compact size surface drive is mounted precisely on the wellhead. It is used to transfer rotary movement from electric engine to the sucker rod string as well as to seal wellhead. Surface drive of PCP is used for production of high and middle viscosity oil, oil with high solids content and watercut. At the same time it allows to decrease expenses for energy consumption up to 20%.

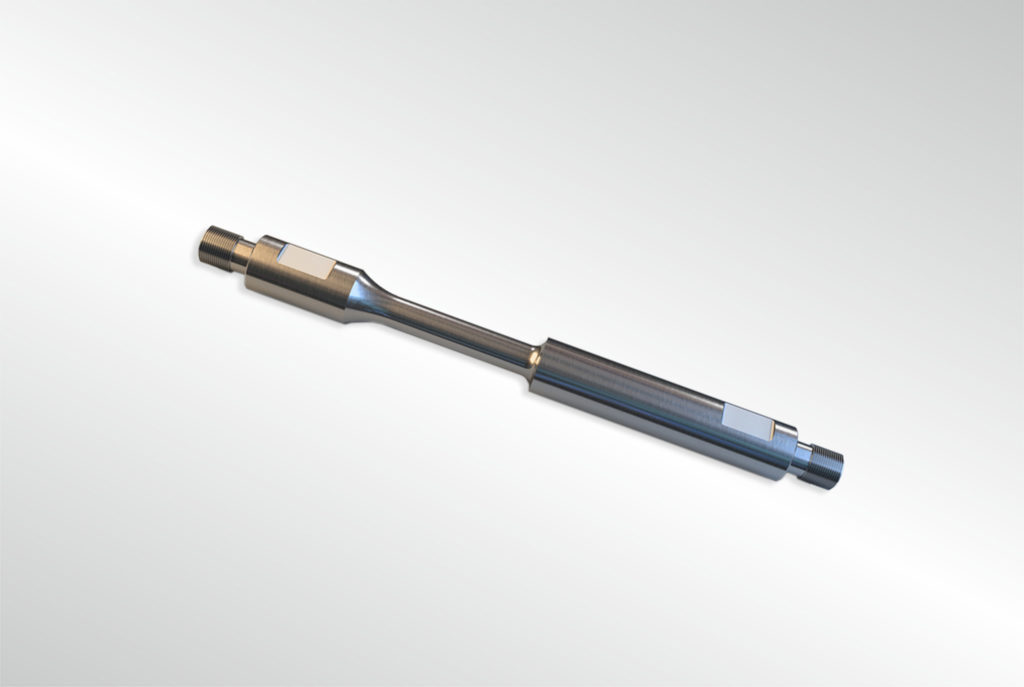

Wellhead polished rods

ELKAM supplies polished rods with nominal diameters 28, 32, 38 and 42 mm with the length from 2.5 to 8 meters. Also we supply hollow polished rods with nominal diameters 32, 38 and 42 mm with the length from 3.5 to 8 meters. To make the surface of our rods wear and corrosion resistant and as the result to increase their runlife our company applies unique technology of flame coating with hard-alloy materials.

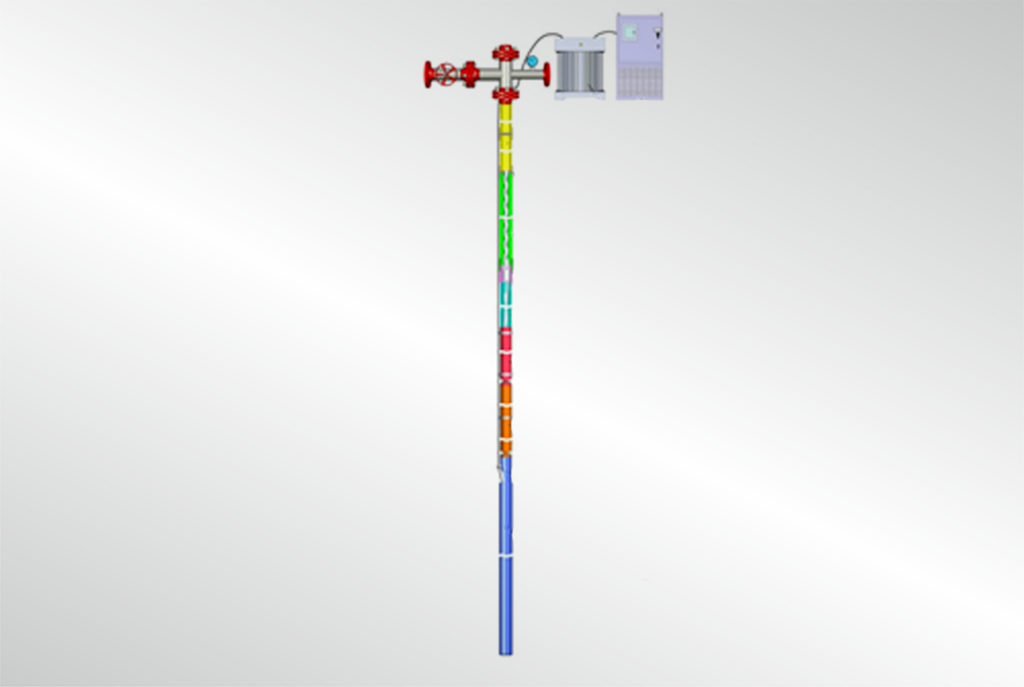

Subsurface drive

Subsurface drive (submersible electric motor) serves as a converter of electric power to mechanical power of pump rotation. Subsurface drive operates in deep, deviated and horizontal wells. It is also efficient for production of high viscosity oil with high solids content. The main advantages of submersible electric motor are: absence of sucker rods parting and unwinding, exclusion of probability of improper fitting of rotor and stator, lower power consumption.

Control box

Control box is used to control operation of PCP electric engine with a capacity from 3 kW to 45 kW. ELKAM provides control boxes with VSD and intellectual control boxes. Operation of control boxes with VSD ensures reliable operation of pumping unit and electric engine protecting from overheating, overloading, short circuiting, etc. Application of intellectual control boxes allows to automatize equipment operation, optimize oil production, remotely control and change the main parameters of system operation.

Progressive cavity pump

Progressive cavity pump (PCP) is used for pumping formation fluid with high viscosity, high GOR and high solids content. PCPs operation principle is rotary liquid displacement. These pumps are applied in such complicated operating conditions as viscous oil (200 cPs), high gas content upon high bubble point, low flow ratio. Also PCPs are adopted for pumping formation fluid with high solids content (up to 400 mg/l).

Protectors

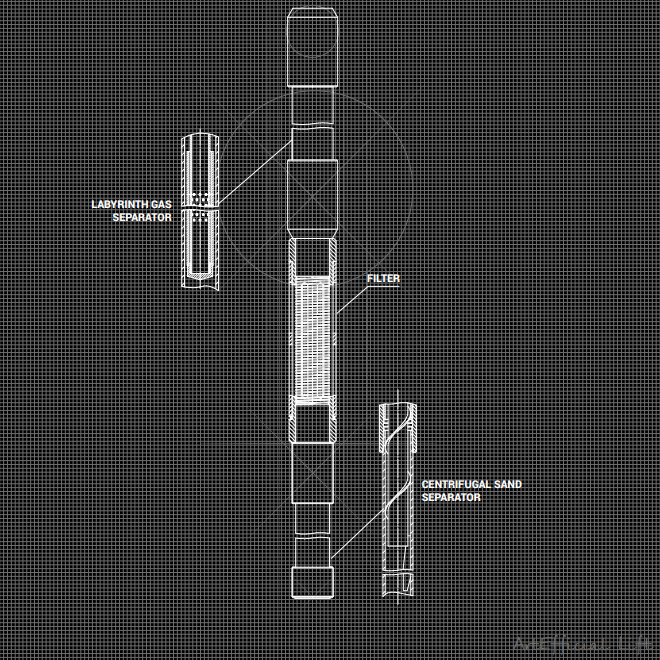

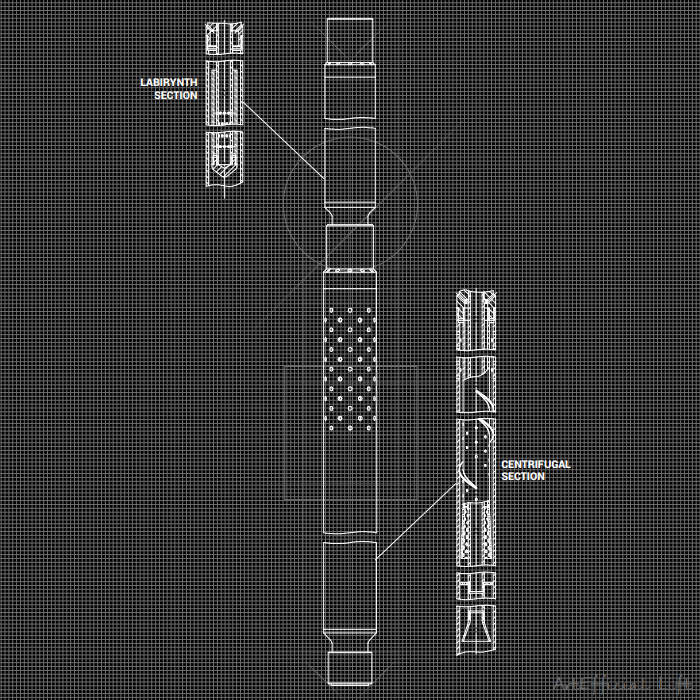

Protectors – gas sand anchor, filter with adjusting clearance, sand prevention pipe, gas separator, etc. are applied for protection and decrease of wearing of pump main parts as well as for increase of pump flow rate in complicated oil production conditions such as high content of solids and gas.

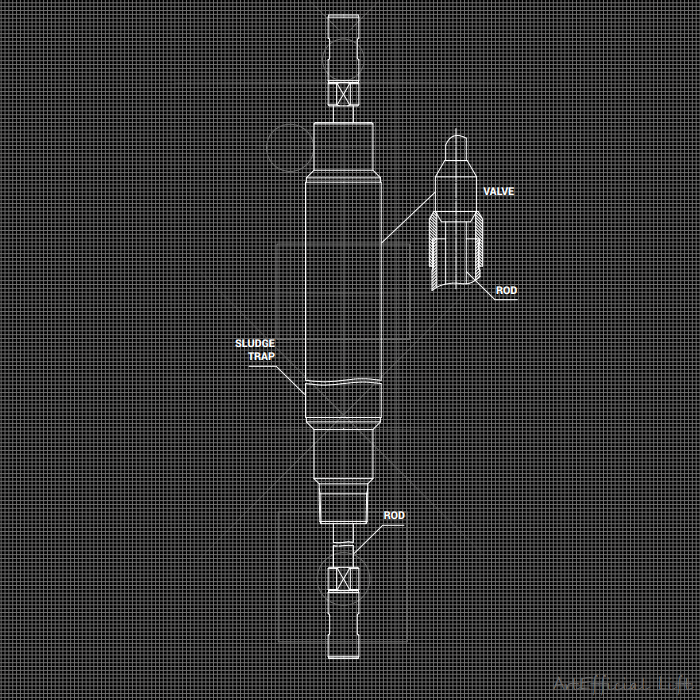

Sand-gas anchor

Sand-gas anchor neutralizes negative effects of solids and free gas at sucker rod pump intake and increases pump MTBF.

Gas separator

Gas separator is designed to substantially reduce concentration of free gas at pump intake.

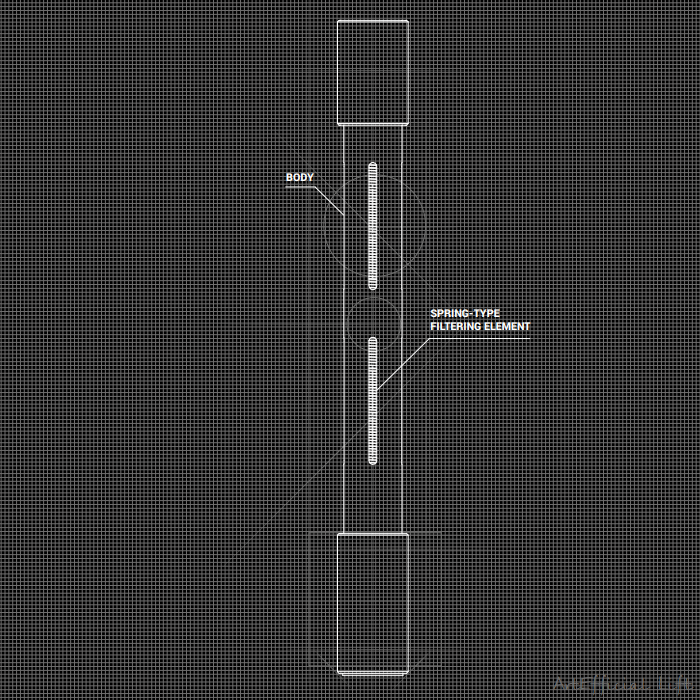

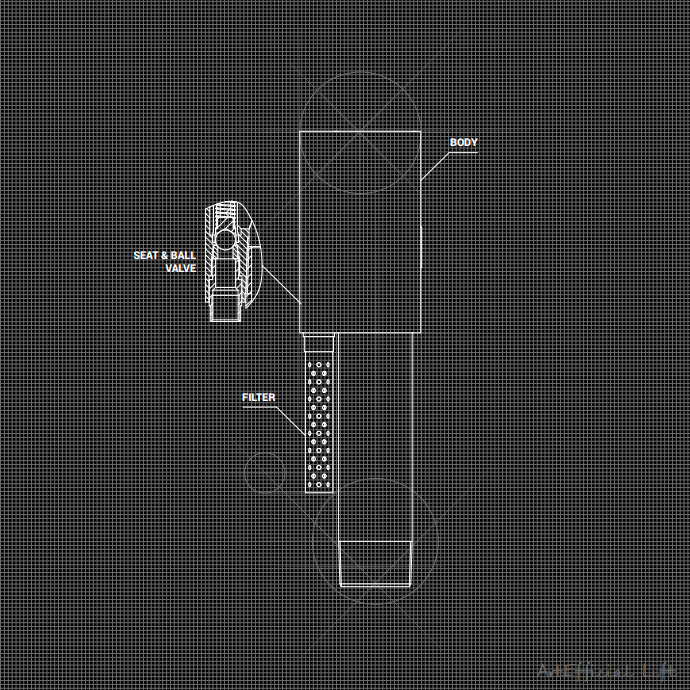

Sand screen filter adjustable

Adjustable sand screen filter neutralizes negative effects of solids on sucker rod pump intake and reduces risk of failure of downhole equipment.

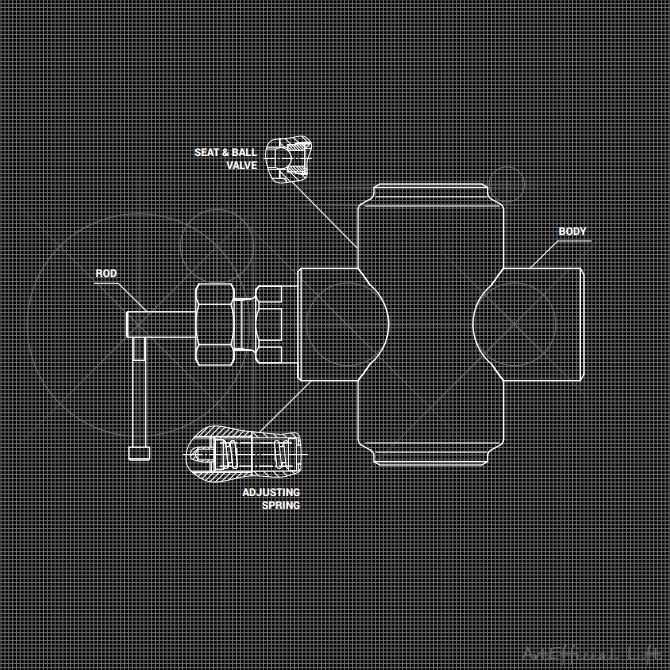

Valves

ELKAM supplies wide range of valves for sucker rod pumps – flush valves for flushing of tubing string using injection of special fluids, well killing and treatment of formation upon tubing string shut on wellhead; valves with breakable plug and membrane valves for fluid draining from tubing string upon pullout.

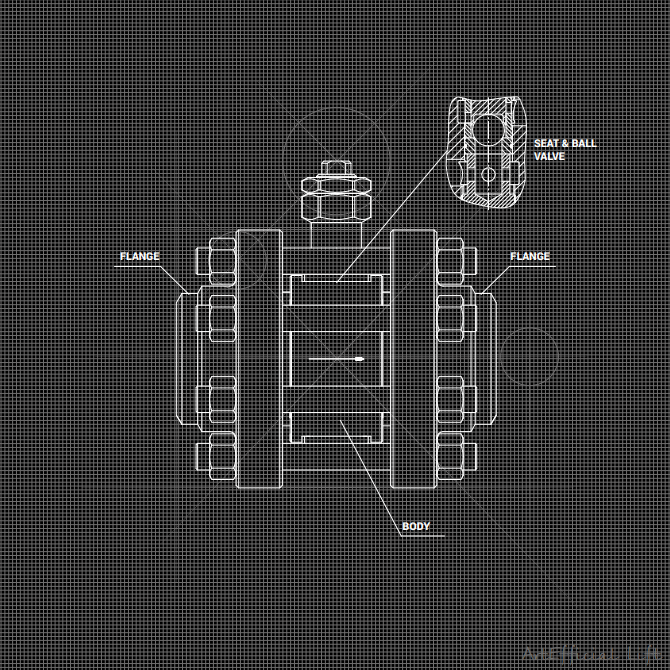

Bypass check valve

Bypass check valve ensures reliable discharge of gas from annular space into production line.

Non-freezing check valve

Non-freezing check valve ensures reliable discharge of gas from annular space into production line.

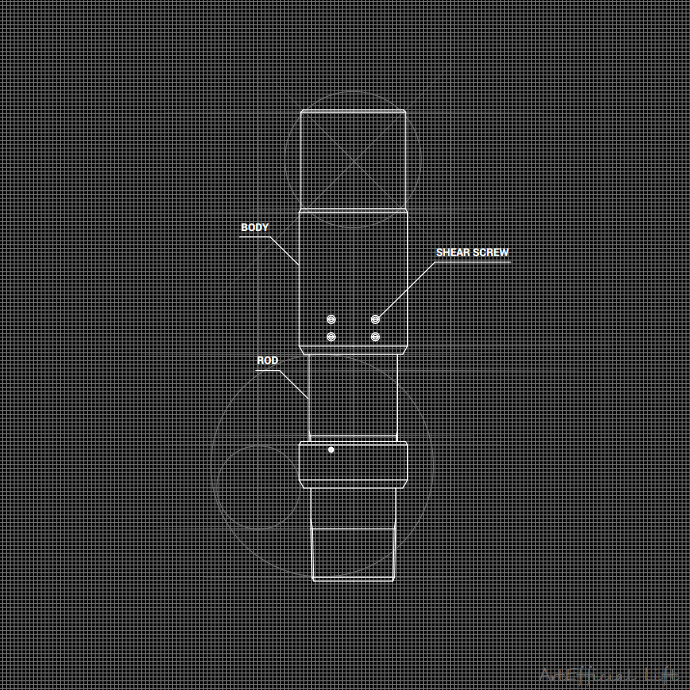

Drain valve with shear screws

Drain valve with shear screws is used as component of various downhole assemblies and is preset at well site right before installation.

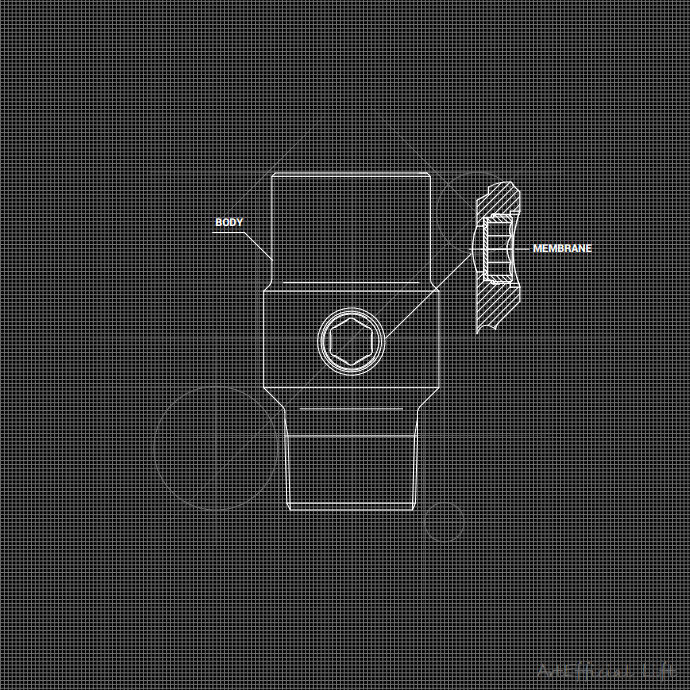

Membrane drain valve

Membrane drain valve can be used with any type of subsurface pump membrane can be replaced at well site.

Bypass gas valve

Bypass gas valve provides stable gas discharge from annular space and doesn’t require any maintenance during operation.

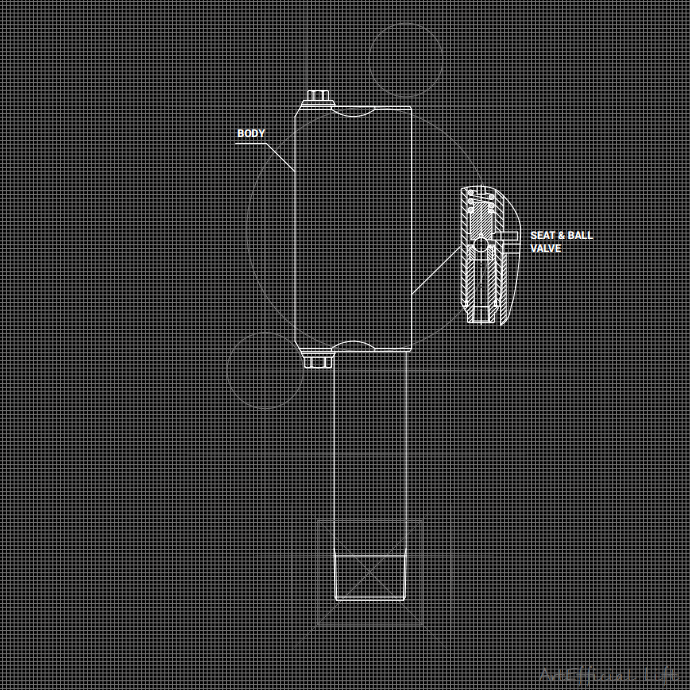

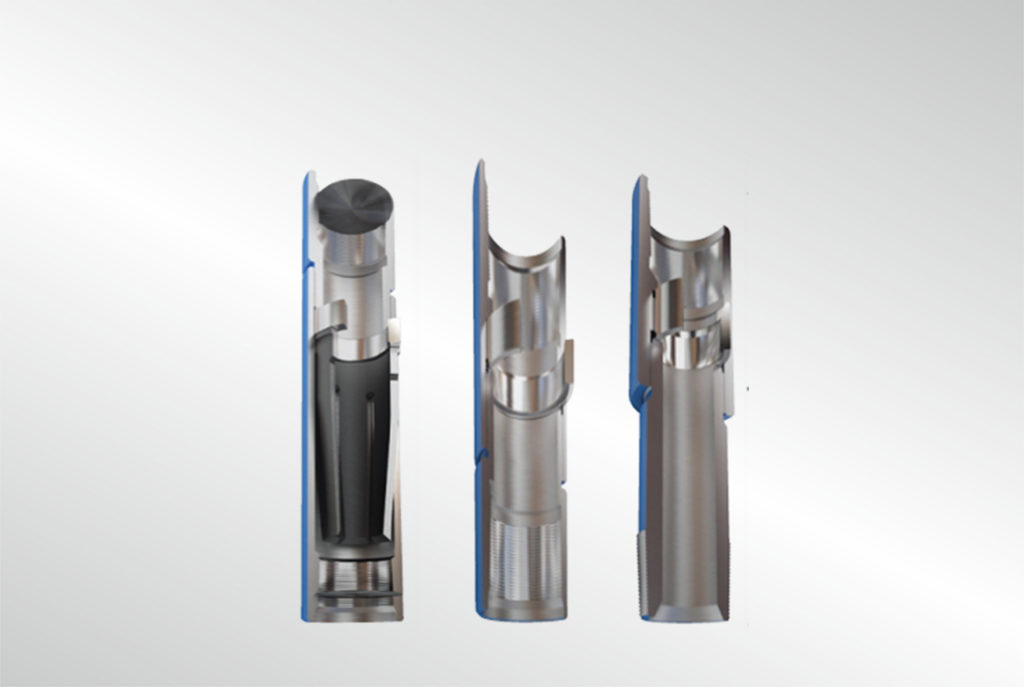

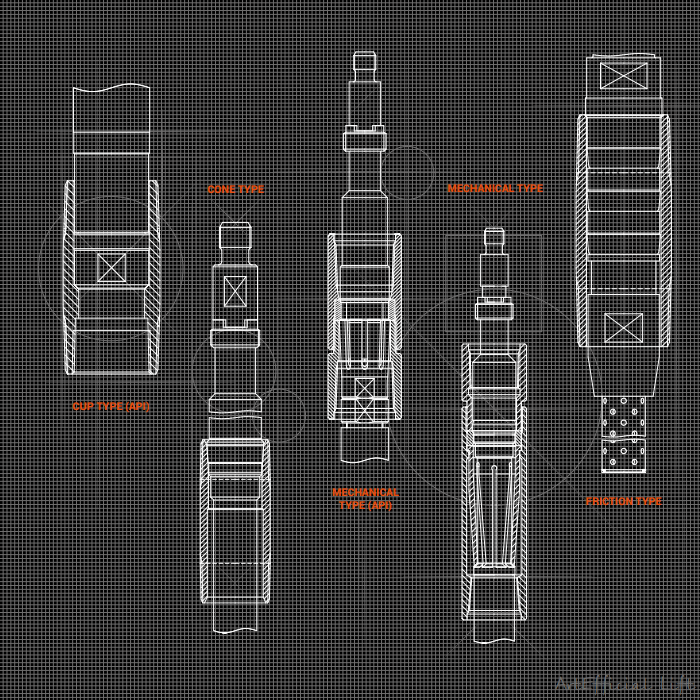

Seating assemblies

Seating assemblies are used for insert pump installation inside tubing and hold of liquid column above the pump. We supply collet seating assemblies designed in accordance with the Russian standard GOST of ОМ-60, ОМ-73, ОМ-89 types; seating assemblies of NМ-60, NМ-73, NМ-89 types manufactured according to API standard; cone in cone type ОА-32, ОА-44, ОА-57; cup type; friction type.

Seating assembly

Seating assembly is integral part of insert sucker rod pumps and is set in borehole at determined depth.

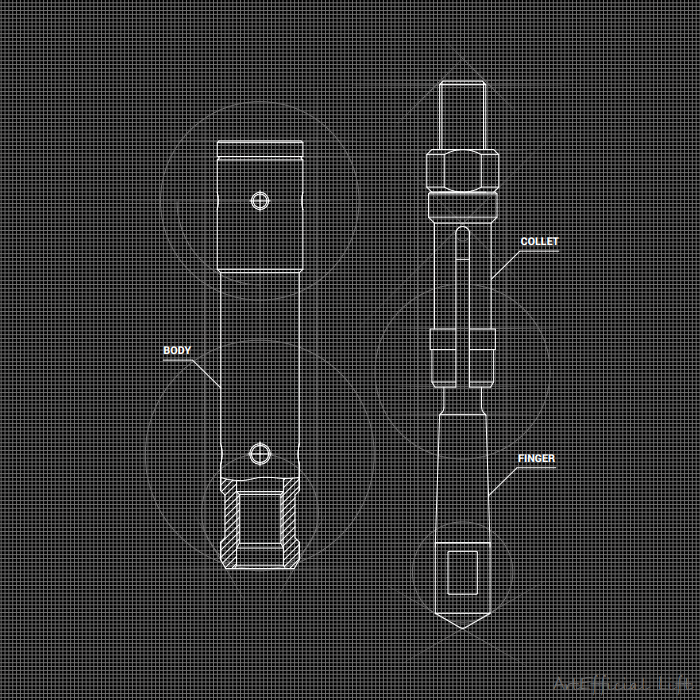

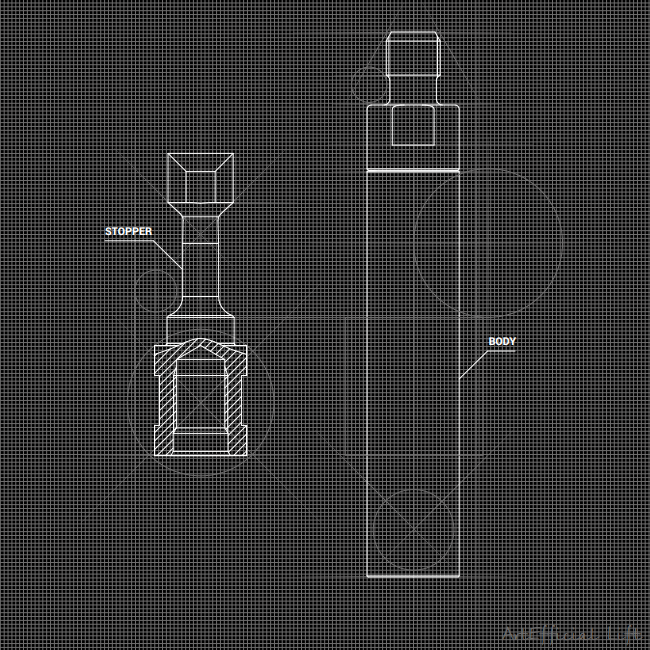

On/off tools

ELKAM manufactures and supplies on/off tools used for connection of plunger of a pump to sucker rod string upon installation of a barrel in combination with plunger as well as on/off tools for connection/disconnection of SRP plunger to/from sucker rod string. It is also used when SRP plunger diameter exceeds tubing string ID.

On/off tool

On/off tool is designed for installation/deinstallation of sucker rod pump when plunger OD exceeds tubing ID.

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia