Polished rod

ELKAM company supplies polished rods with nominal diameters 28, 32, 38 and 42 mm with the length from 2.5 to 8 meters. Also we supply hollow polished rods with nominal diameters 32, 38 and 42 mm with the length from 3.5 to 8 meters. To make the surface of our rods wear and corrosion resistant and as the result to increase their runlife our company applies unique technology of flame coating with hard-alloy materials.

Polished rod

ELKAM produces polished rods up to 11 meters long, with nitrided, spray metal or plain working surface.

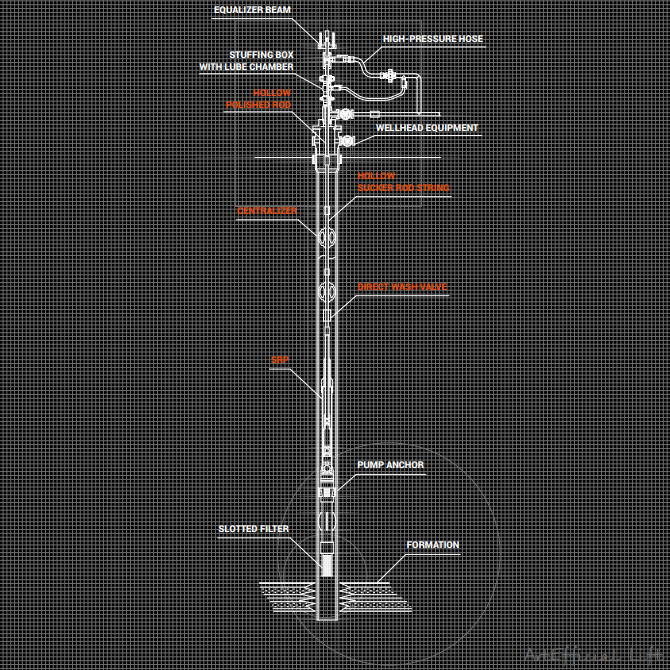

Hollow polished rod

Hollow polished rod is used as component of dual completion, production, heating and washing equipment.

Sucker rod pump set

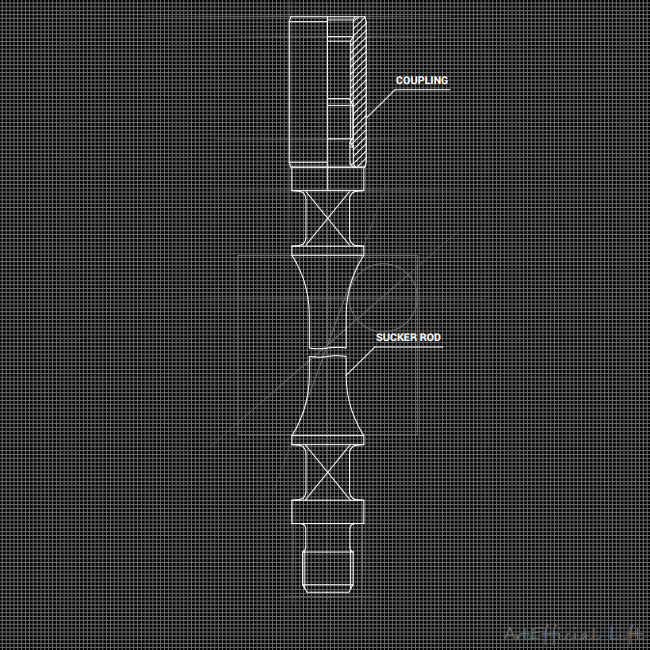

Sucker rods are applied to be round metal stem with hot shaped connecting ends. ELKAM supplies sucker rods manufactured in accordance with API-11B standard with the diameters 16, 19, 22 and 25 mm of K, C, D and D spec. grades. We developed a unique product – sucker rod ShNK-29 of D grade with coupling diameter 54 mm which can be applied with 2 7/8” tubing by contrast with standard sucker rod 29. It allows to produce oil from the depth over 2500 meters.

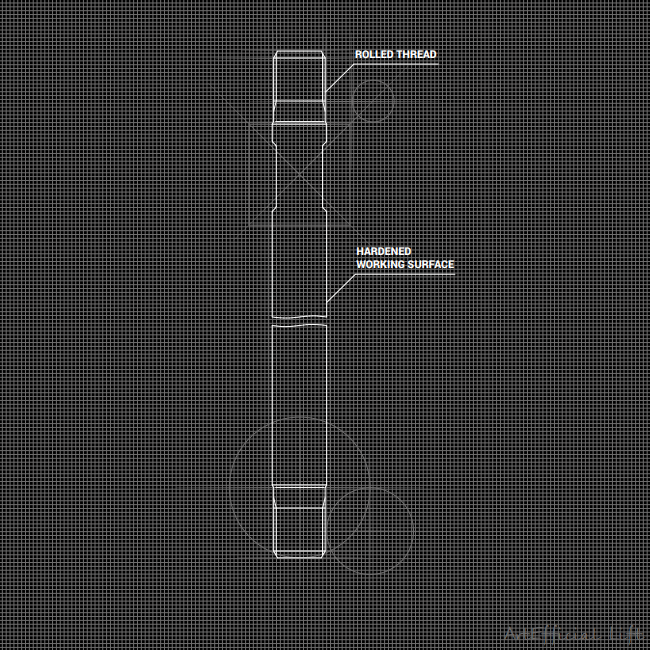

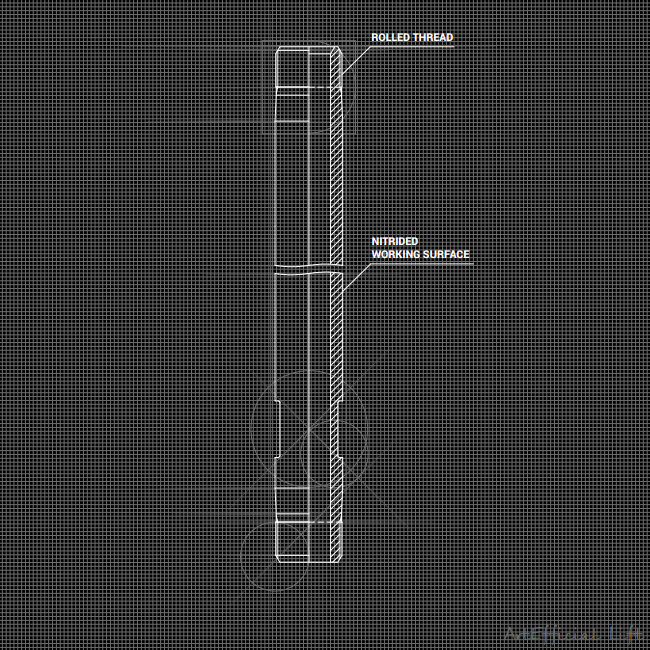

Conventional sucker rod

Solid sucker rod is manufactured in various sizes and grades. Length 20-315 inch (500-8000 mm), clip-on and moulded centralizers are available.

Fiberglass sucker rod

Fiberglass sucker rod has a variety of advantages in comparison with steel sucker rod such as increase of pump setting depth up to 2500 meters, decrease of horsehead maximum load when rods string moves upwards and decrease of ARWD influence on rods string. Line of fiberglass sucker rods supplied by ELKAM includes rods with nominal diameter from 19 to 29 mm of K, C and D grades, manufactured in accordance with API-11B standard.

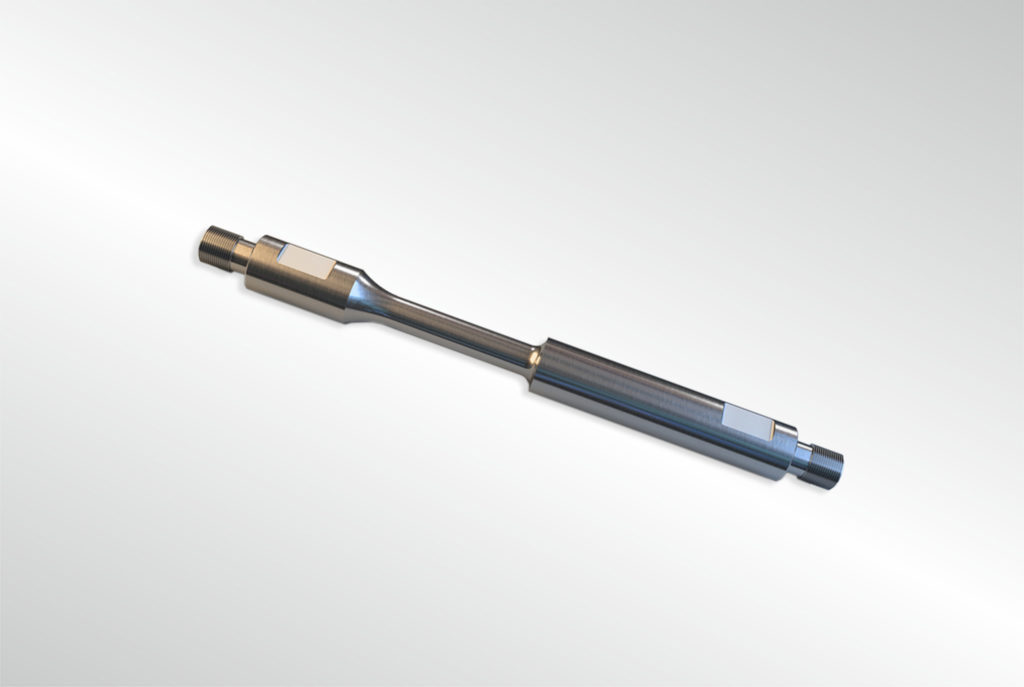

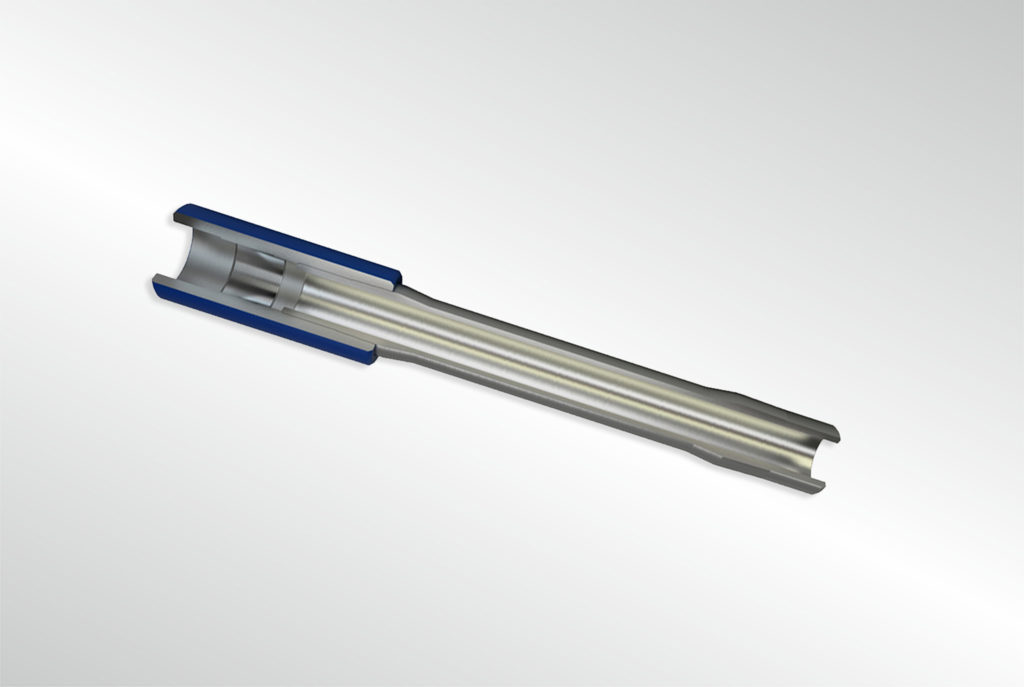

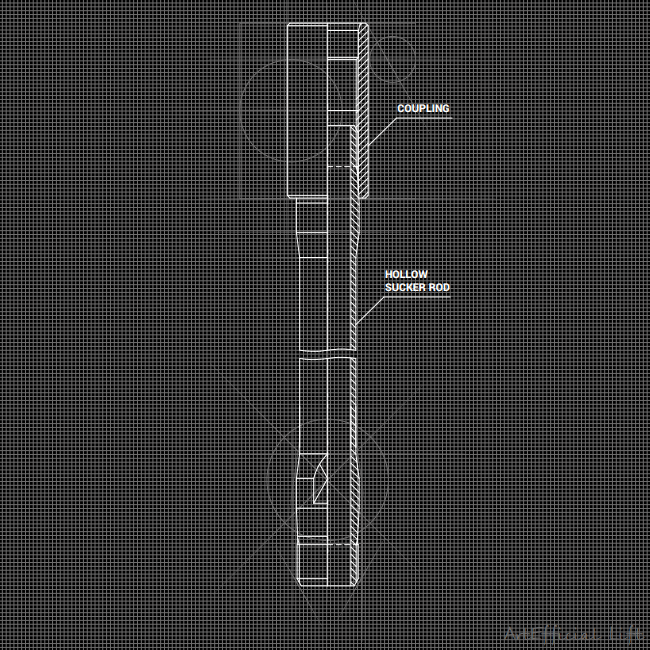

Hollow sucker rod (HSR)

Hollow sucker rods are designed to transfer driving energy from the surface drive to the plunger of submersible pump or PCP rotor. Also they are applied for simultaneous oil production, washover operations of tubing string from ARWD and ice, injection of chemicals and steam during bottom-hole formation zone treatment. Our company manufactures and supplies 5/8″, 3/4″, 7/8″ and 1″ hollow sucker rods from 0.5 to 8 meters.

Hollow sucker rod

Hollow sucker rod is used as component of dual completion, heating and washing equipment.

Tubing-free production set

Tubing-free production set provides efficient operation of wells with small ID casing without tubing strings.

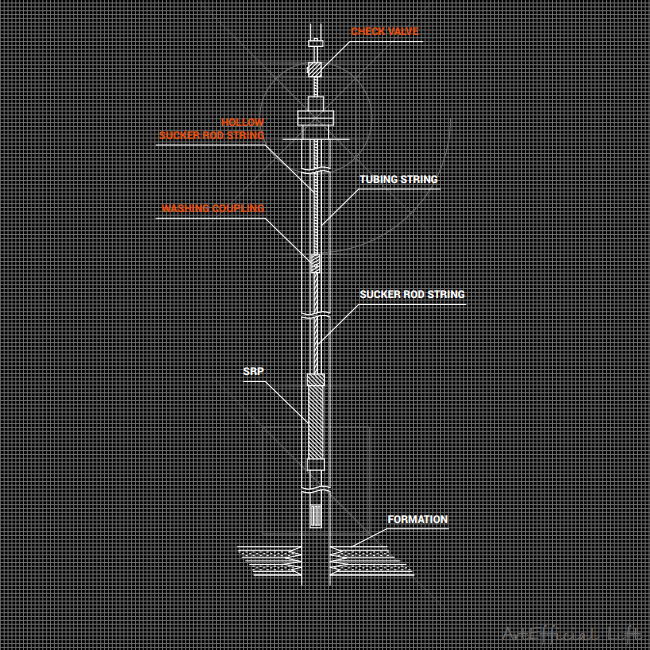

Deparaffination equipment for SRP

The equipment is designed for tubing heating and flushing during SRP operation.

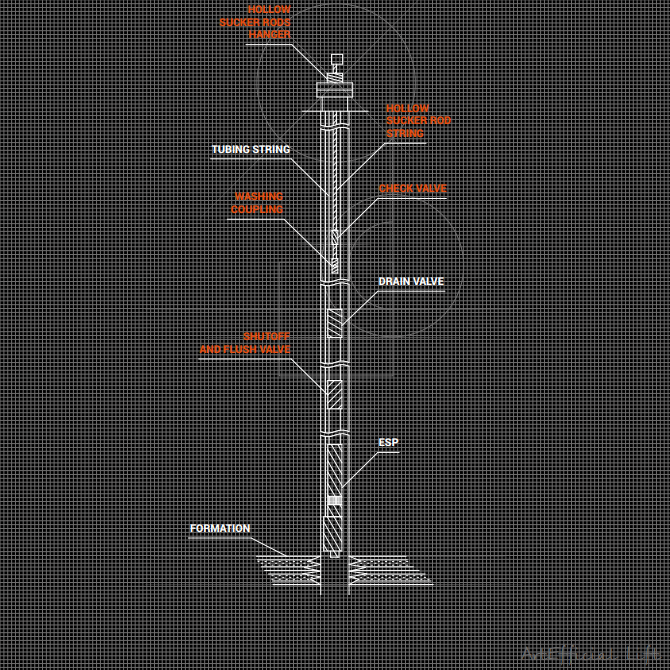

Deparaffination equipment for ESP

The equipment is designed for tubing heating and flushing during ESP operation.

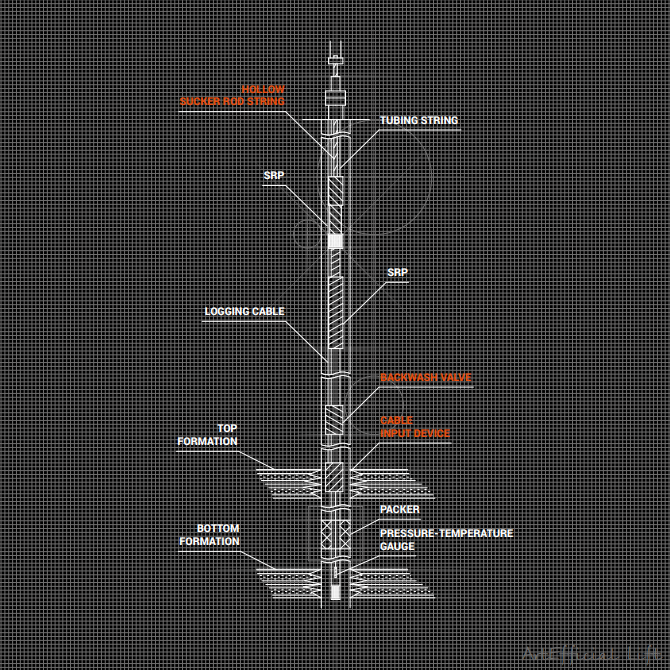

Dual completion SRP-SRP

Dual completion SRP-SRP is used for simultaneous dual oil production from two formations.

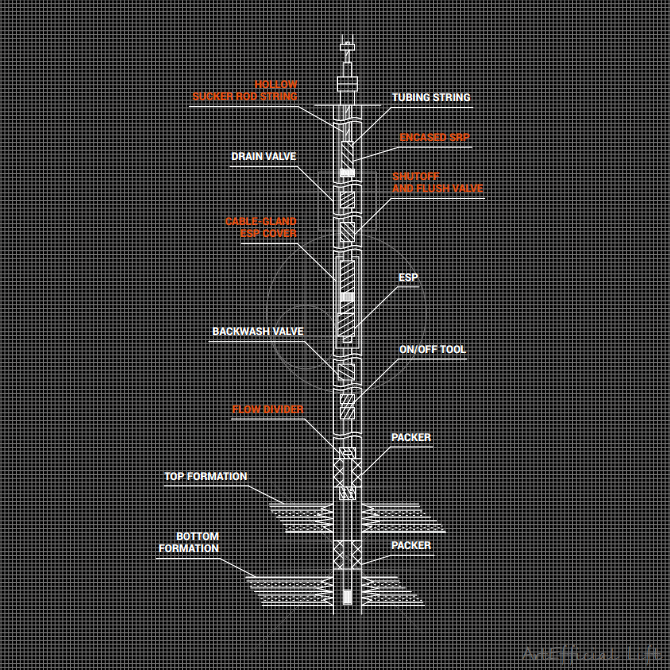

Dual completion ESP-SRP

Dual completion ESP-SRP equipment is used for simultaneous dual oil production from two formations according to scheme: bottom – ESP, top – SRP.

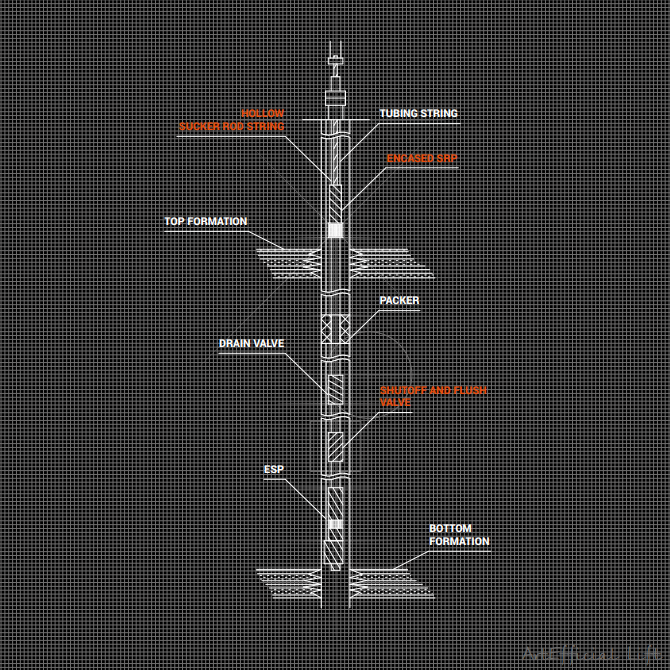

Dual completion SRP-ESP

Dual completion SRP-ESP equipment is used for simultaneous dual oil production from two formations according to scheme: bottom – SRP, top – ESP.

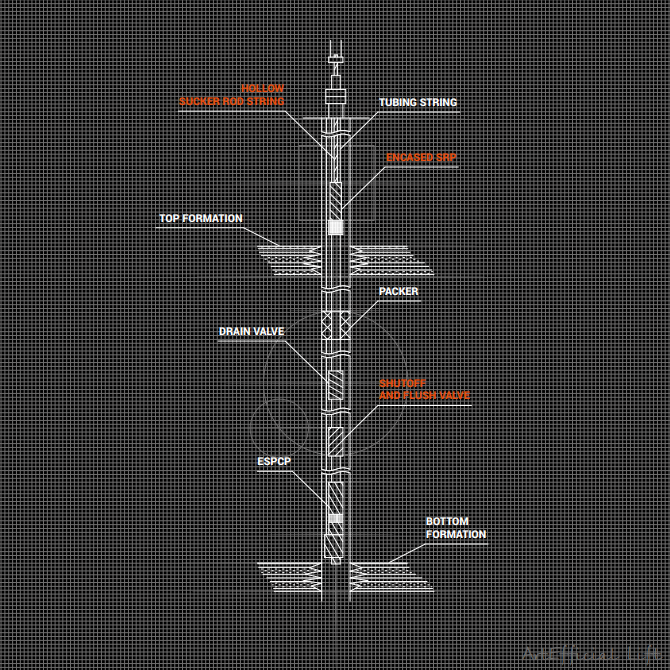

Dual completion ESPCP-SRP

Dual completion ESPCP-SRP equipment is used for simultaneous dual oil production from two formations according to scheme: bottom – ESPCP, top – SRP.

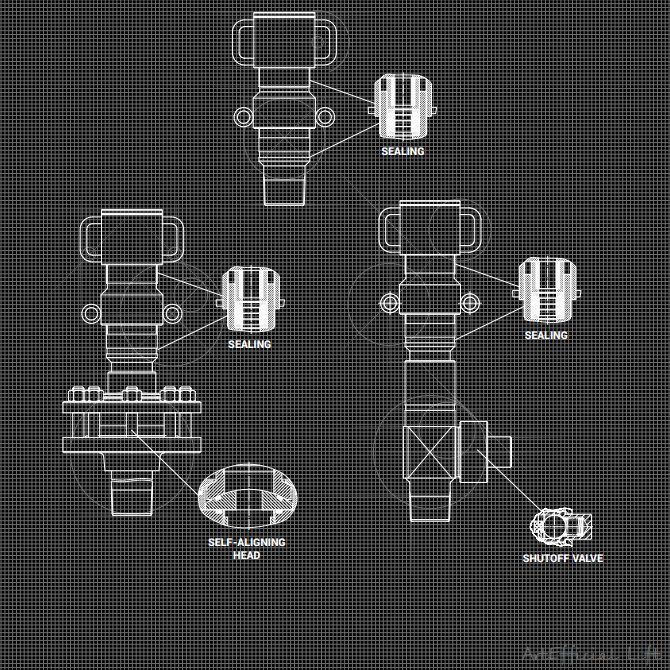

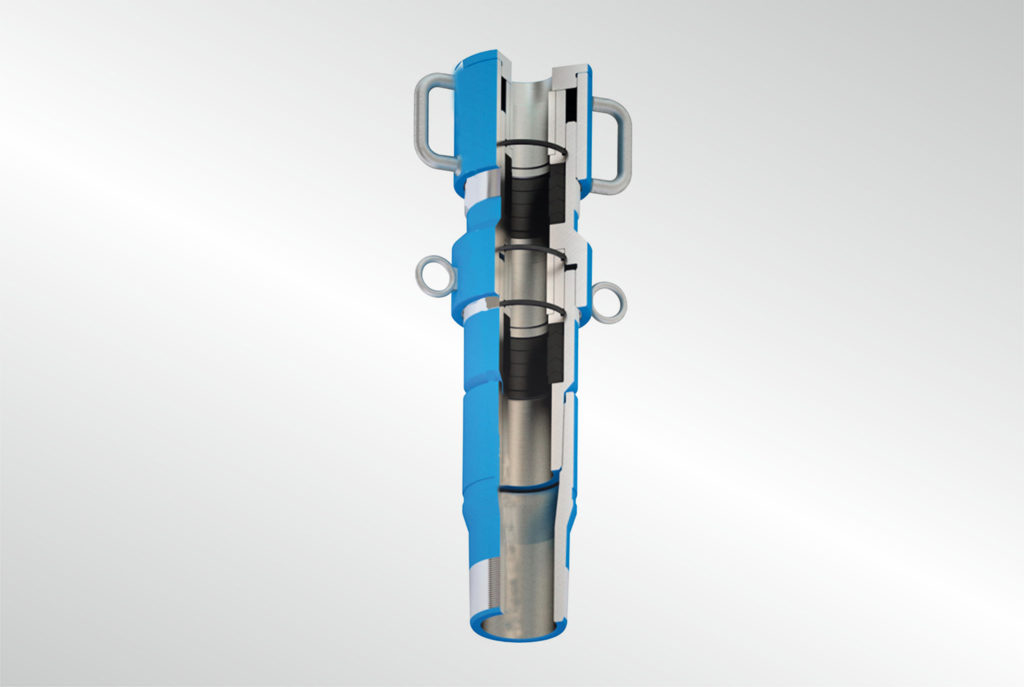

Stuffing box

Stuffing box is applied for polished rod sealing in sucker rod wellhead equipment for oil production by sucker rod pump. Stuffing boxes can be supplied in corrosion-resistant design K1 (well conditions – oil and gas with CO volume content up to 6%) and K2 (well conditions – oil and gas with CO and H2S volume content up to 6% of each of them). At Customer’s requirement we can supply stuffing boxes in high temperature resistant design (up to 300 °C) as well as stuffing boxes with shut-off valve and self-adjusting head.

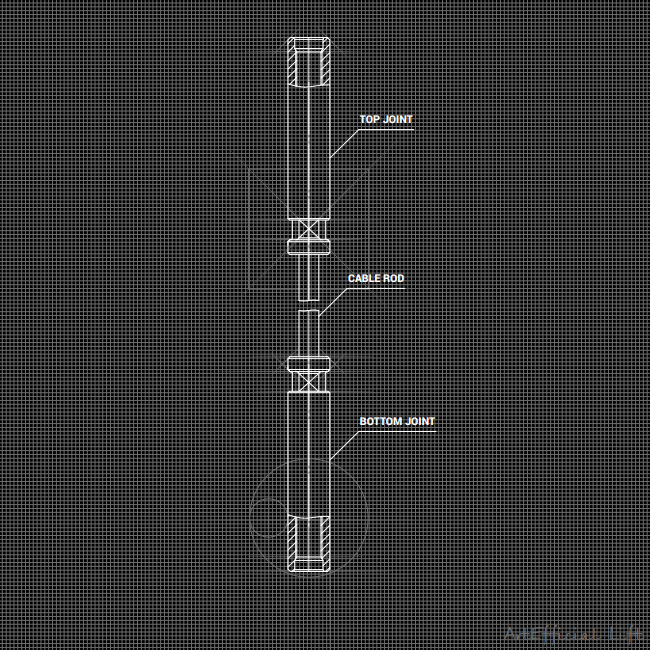

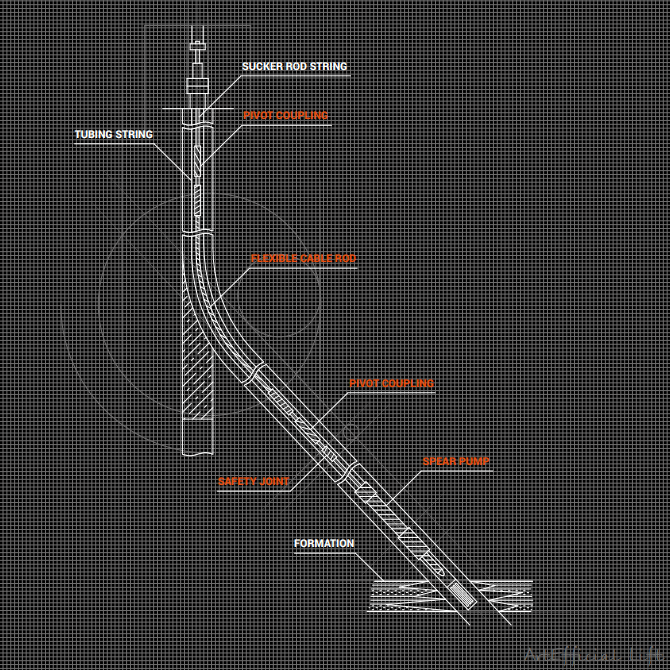

Flexible cable rod

Flexible cable rod equipment set is used for SRP operation in side-holes of small diameter, inclined and highly deviated wells (up to 90°). Equipment set consists of sucker rods string, tubing string, flexible cable rod, crossover coupling, specialized SPeaR pump and slot filter. Application of cable rod at the place of maximum inclination angle allows avoiding wearing of tubing string by sucker rod couplings due to decrease of friction between rods and tubing.

Flexible cable rod

Flexible cable rod is designed for operation of highly deviated wells and small ID sidetracks.

Flexible cable rod set

Flexible cable rod set increases pump setting depth in sidetrack and provides additional oil production.

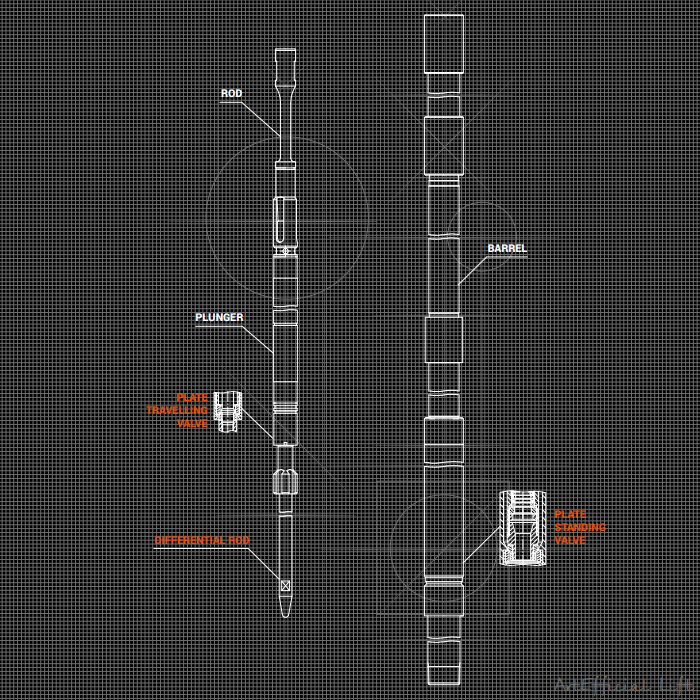

SPeaR pump with plate valves

SPeaR pump with plate valves provides operation in wells with highly viscous oil, deviated wells up to 90° and sidetracks. It is also widely used in combination with flexible cable rod for highly deviated wells.

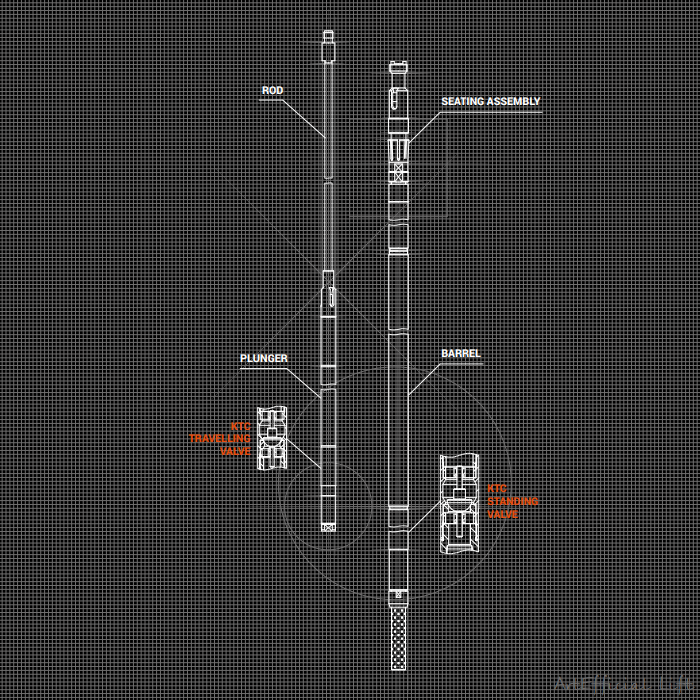

Sucker rod pump with KTC hemisphere valves

SRP with KTC hemisphere valves provides oil production in wells with deviation angle up to 70 degrees and high viscosity oil.

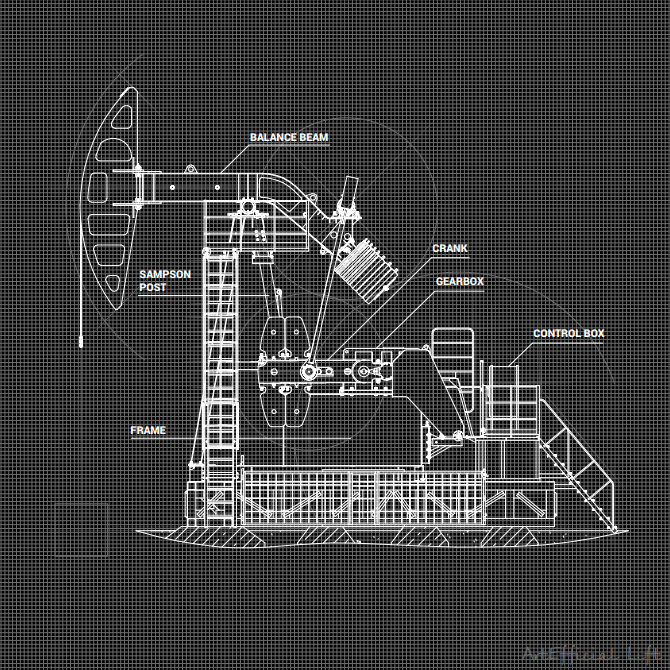

Beam pumping unit

Beam pumping unit is a mechanism which puts a downhole pump into operation during artificial lift. It turns rotary movement of engine shaft into reciprocating movement of sucker rods and sucker rod string. Our company supplies beam pumping units with load capacity 6, 8 and 12 tons and stroke length from 1.2 to 5 meters. These beam pumping units allow efficient oil production from the depth up to 2000 meters.

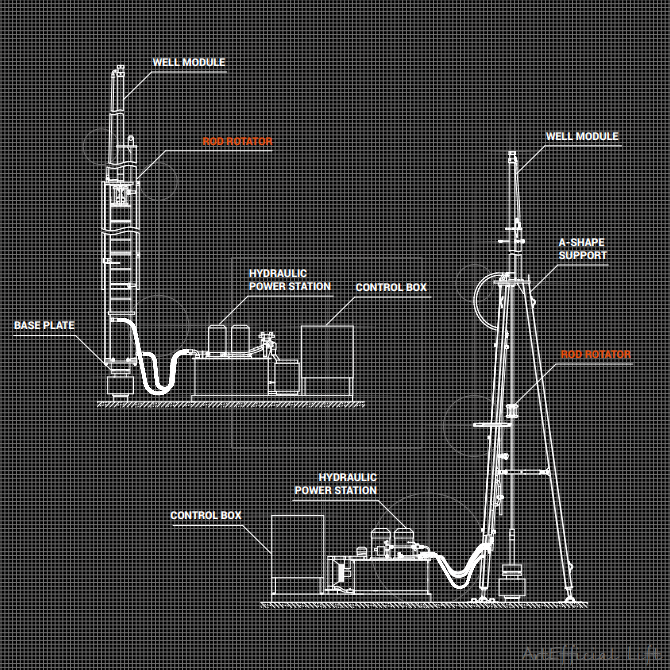

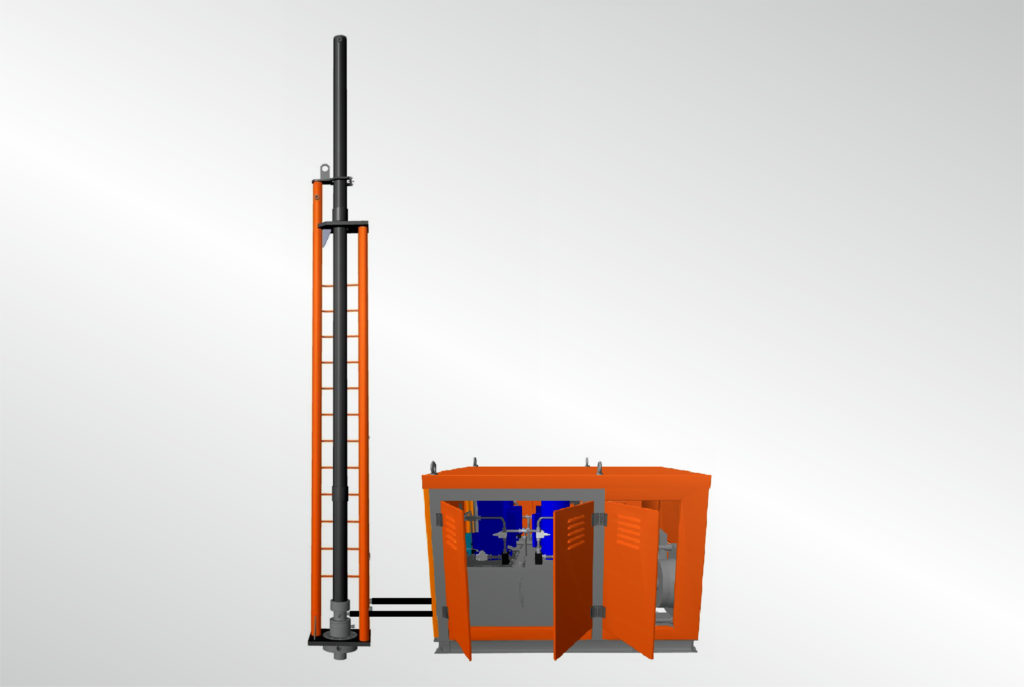

Hydraulic pumping unit

Hydraulic pumping unit (HPU) is an alternative to beam pumping unit used for oil production by SRP. It is installed on the well site and can be applied for dual operation of wells, implementing simultaneous double lift. We supply HPUs – modular, closed-type and mobile – with loading capacity 6, 8, 12 and 16 tons, stroke length of polished rod up to 6 meters and 3-5 strokes per minute.

Belt drive

Belt drive is used for putting sucker rod pump into operation during well fluid production. It allows operating high rate wells including those with high viscosity oil, and wells with additional casing strings of small diameter without efficiency loss. Belt drives line of our company includes drives with loading capacity from 8 to 20 tons and stroke length of polished rod up to 8 meters.

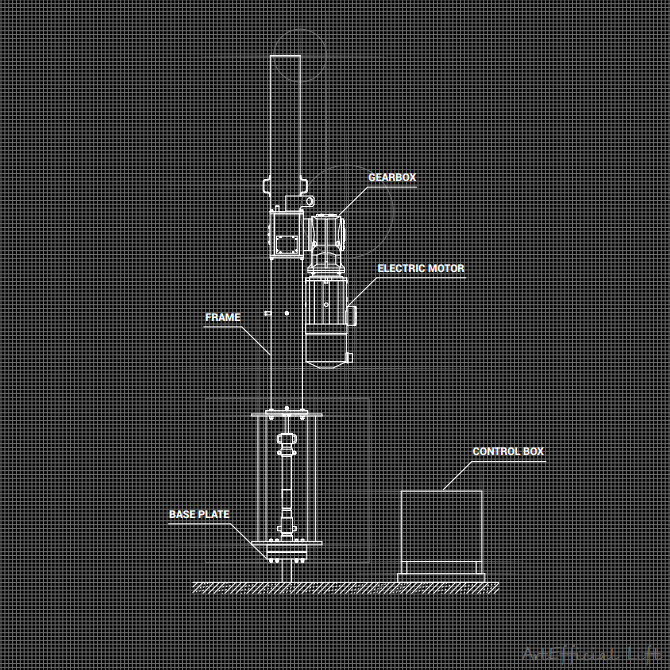

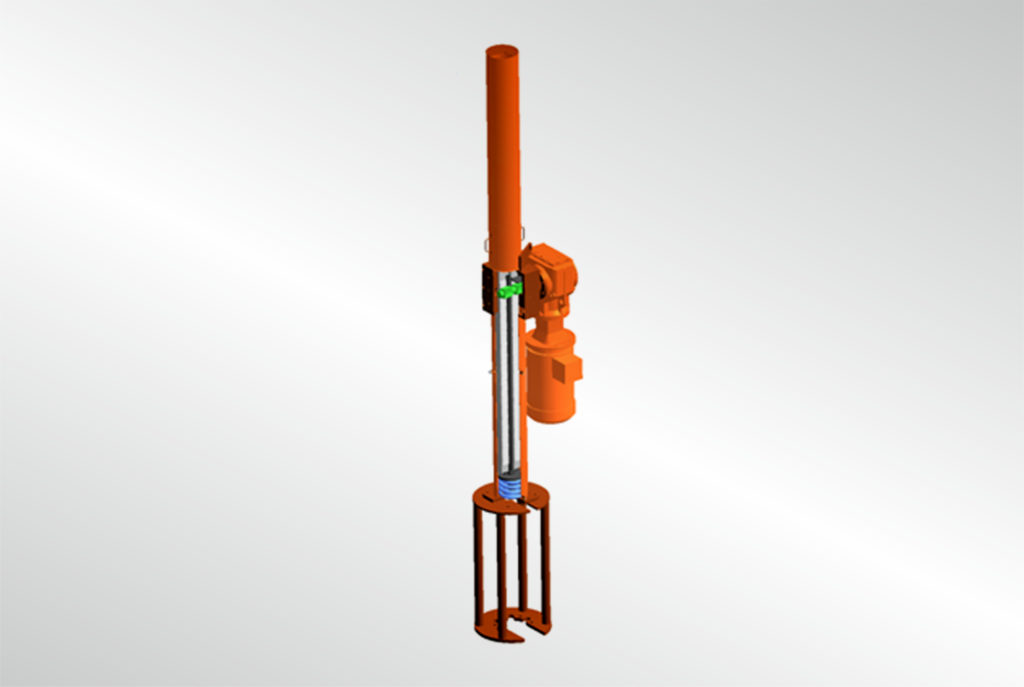

Linear rod pump

Linear rod pump (LRP) of SRP is a rack-and-pinion drive which ensures reciprocating movement of downhole pump in a well by rotating of induction motor back and forth. The drive consists of mounting base, electric engine, gear box, gear, pillar (body), removable cover, rod clamp and control box. Linear drives manufactured by ELKAM have stroke length up to 1.6 meters, loading capacity 8 tons and explosion-proof design.

15b, Usolskaya Street, Perm, Russia

15b, Usolskaya Street, Perm, Russia